Kiln Axis Alignment

Introduction

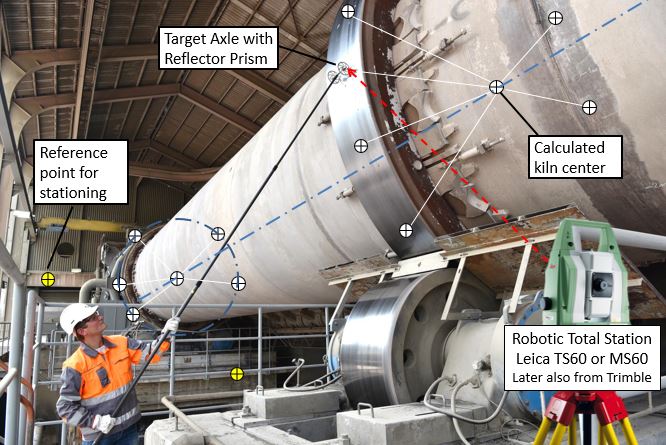

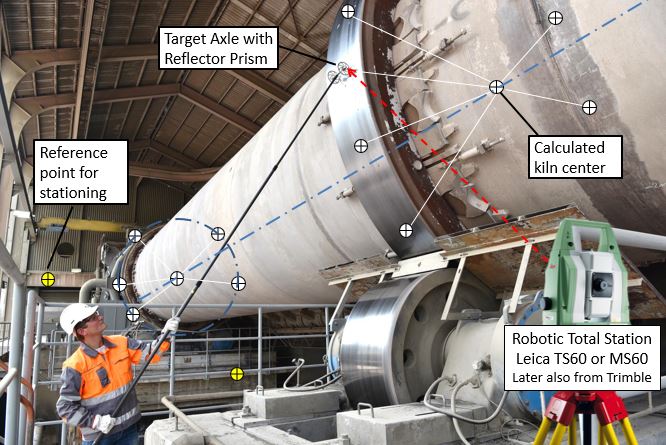

The Kiln Axis Alignment system is to determine the axis deviation on a kiln or dryer or any other slowly rotating, large cylinders. The system is independent if the equipment is in operation or stopped. The steel shell of rotary kilns is exposed to elevated mechanical stresses in case of misalignment. In case of excessive deviations, the shell might suffer from circumferential cracks and in extreme cases up to a kiln collapse.

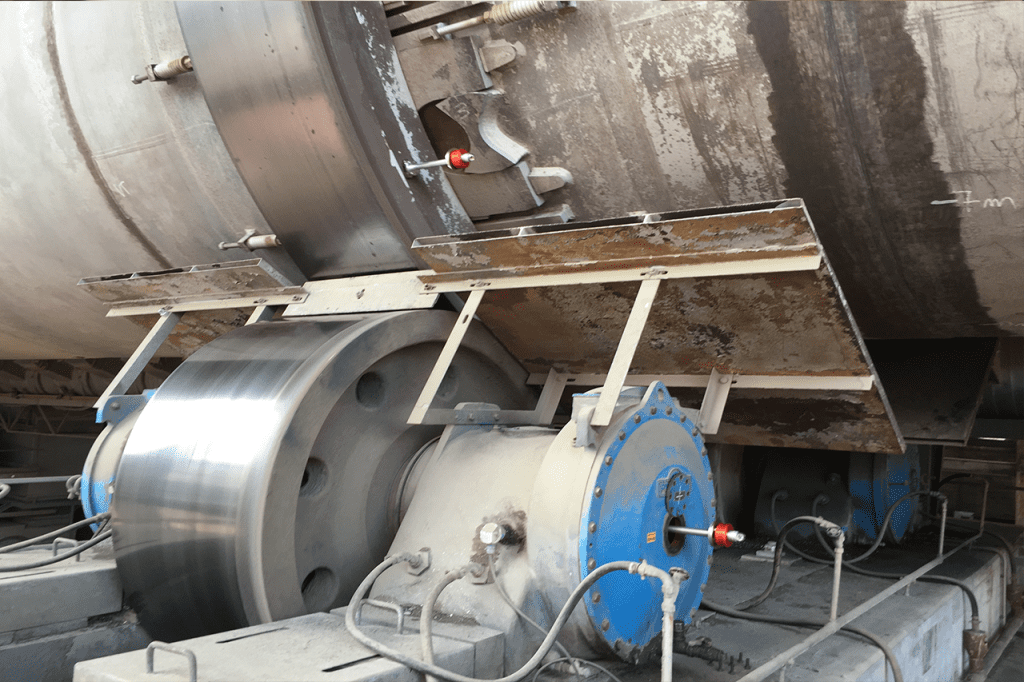

The thrust rollers on a rotary kiln need to be positioned in line with the kiln axis or only a few millimetres towards the in-running side.

This new method allows one to measure the position precisely and fast while the kiln is in operation.

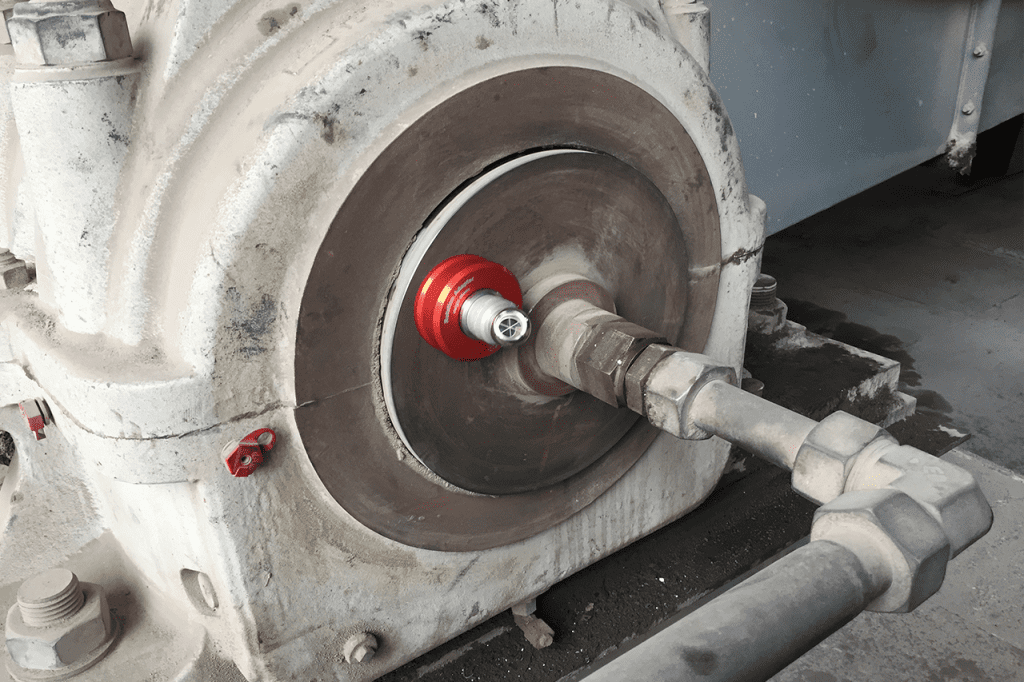

The specially made 360° prism is tracked and measured by the theodolite while it is rotating on the roller.

The software, the Measurement Studio, fits a circle into the measured points and calculates the centre position of the thrust roller.

The new method for kiln axis measurement brings several advantages

Independent if kiln is in operation or stopped

Easy to measure

- no specialized geo surveying knowledge required

- 1…2 days training is sufficient

- Low number of sources for errors

- The operators are in contact via the hand free intercom

Fast

- A kiln with 3 piers can be measured easily within halve a day, traditional methods require up to several days

- Diameter of rollers and tires have not to be measured

- Typically only two positions of theodolite are required

Easy to analyze

- The results are immediately visible in the PC

- Possible erroneous measurements can be repeated at the spot

- No transfer to other software required

- Unmistakable visualization in 3D

- The data can easily be shared and distributed via e-mail