Wireless Vibration Sensor | Sparrow

We understand that each industrial operation is different, and your factory may consist of various types of machinery. The importance of each machine may vary, but every piece of equipment, no matter how important, plays a role in helping you work efficiently and effectively. Downtime and maintenance disruptions can be costly and pose safety risks for your employees.

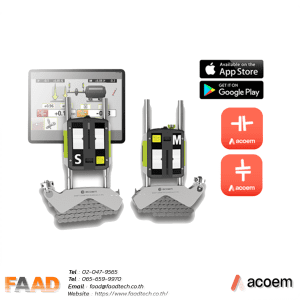

The Wireless Vibration Sparrow is a new model of vibration monitoring sensor offered by ACOEM. It provides a comprehensive inspection solution, from portable models to real-time and wireless data acquisition. You can choose which sensor system to use with your assets, whether you invest in Sparrow, Eagle, Falcon, MV-x, Machine Defender, or a combination of all. Your data can be easily connected and managed in one place for smooth diagnostics and analysis with Nesti4.0

Features

FLEXIBLE SOFTWARE & HOSTING PLATFORM

FLEXIBLE SOFTWARE & HOSTING PLATFORM

Connect all your data-collecting tools on one software platform with either on-premises or cloud-based storage. Seamless big data integration lets you easily link your machine health information with your data lake via OPC UA (Nesti4.0, Gateway), Modbus TCP (Gateway) or MQTT (Gateway).

COMPACT, DURABLE & EFFORTLESS DEPLOYMENT

COMPACT, DURABLE & EFFORTLESS DEPLOYMENT

At only 33mm high, the Sparrow sensor can be deployed anywhere. Dust, water and solvent-resistant for greater longevity. Operational in ambient conditions of -40 °C to +80 °C. Simple and straightforward to install and operate with your precision data available within minutes.

24/7 ACCESS TO ACTIONABLE DATA

24/7 ACCESS TO ACTIONABLE DATA

Simplifies your decision-making process and enhance your operational efficiency with information from every machine in your network available in one place at any time thanks to the Acoem WebPortal.

LOW COST OF OWNERSHIP

LOW COST OF OWNERSHIP

As the Acoem reliability range’s entry-level solution, Sparrow makes monitoring more affordable, especially for large-scale projects. Standard replaceable battery extends your sensor’s lifecycle, meaning no technology redundancy.

ADVANCED DIAGNOSTICS CAPABILITIES

ADVANCED DIAGNOSTICS CAPABILITIES

With the benefit of the Acoem Machine Health Matrix & Shock Finder™ Filter, quickly assess the health of your machines with professional vibration analysis data available on a single screen on any enabled, secure device. Access displays of shocks in the time waveform automatically.

ACCESS TO EXPERTISE

ACCESS TO EXPERTISE

Remote support via our Acoem Advisor service whenever needed. An individually tailored, custom-designed condition-based maintenance program can be developed with data analysis and certified reports from Acoem experts worldwide.

Sparrow providing a good experience for you.

Wireless Vibration Sensor : Sparrow Enhancing the potential of the industry by eliminating limitations, improving visibility, and emphasizing the necessity of proactive maintenance through the Wireless vibration sensor: Sparrow. You have received real-time in-depth data about your BoP, which helps you make proactive decisions and enhance operational efficiency.

By surpassing the boundaries of the past and embracing a world of seamless monitoring, efficiency, and accessibility for everyone, we have incorporated advanced vibration measurement sensors into our system with the Sparrow sensor.

Keep an eye on your machine with Acoem's system.

Our systems, which include diagnostic tools such as Portable vibration Meter, Wireless vibration measurement, real-time vibration measurement. Positioning solution Multiple sensors and more bring together all your asset data in one platform with NESTi4.

Our integrated systems streamline inspection of your machines. It allows you to adjust your strategy based on your priorities. of machinery Save time and ultimately increase efficiency.

Applications

Prepare your maintenance team with comprehensive diagnostic tools for all machines in your factory. Sparrow is designed to save time, energy, and resources, making it suitable for use in all types of industrial work. Whether it’s a small single machine or a larger one, Sparrow offers you more options in terms of inspection capabilities. It is particularly well-suited for assets with a balanced factory inventory, including

- electric motors

- pumps

- fans

- stationary machines without gearboxes (or small gearboxes)

- non-critical assets that were previously monitored by first level data collection vibration meters

- machinery that may have been monitored via basic 4-20mA sensors.

Resources

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.