Water is the biggest threat any oil lubricated system faces. Depending on the application water can cause serious problems for the equipment or safety. Maintain and protect your equipment by monitoring the water content.

Most parameters can be trended well by offline laboratory oil tests. This is not the case when it comes to water ingress. Water is not a by-product of the aging of oil or a result of the usage of the oil. Water ingress can come quickly and without any prior warning. Once established water levels may rise very fast. Therefore a trend analysis in a shore based laboratory does not allow a close enough monitoring of the water content to avoid problems due to a sudden water ingress.

Your benefits:

All parts (sensor, display, battery pack etc.) can be exchanged when needed

Now 30% bigger backlit display for better visibility

Solid rugged metal housing for higher durability

Multiple ranges for exact readings

Multilingual software

No hazardous reagents needed

Undercut in the bottom to assist dosing the chemicals for all tests

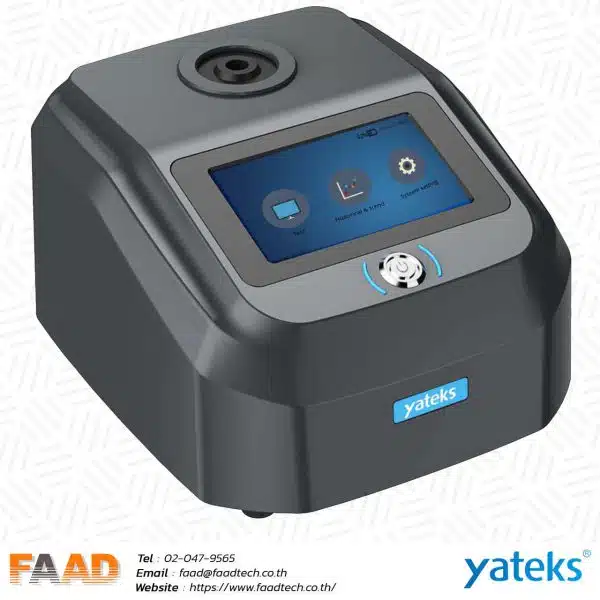

The newly developed Electronic Water in Oil TouchCell does provide highest accuracy on site when testing Water in Oil giving results after a few minutes.

Prevent corrosion, cavitation or failure of your machinery by detecting water in oil, before any damage occurs.

Minimize instability of additive packages and damaging microbe growth by monitoring your oil.

Ordering Information

OTK-CT-11201

Electronic Water in Oil Test Kit

| Range: | 0 – 1500 ppm, (lowest reading 100 ppm) |

| 0 – 6000 ppm, (lowest reading 200 ppm) | |

| 0 – 1 %, 0 – 5 % | |

| Accuracy: | +/- 0.01 % free water |

| Weight: | 490 g |

| Test time: | 5 minutes |

| Reagents: | non hazardous |

| Memory: | last 10 readings for each individual oil |

OTS-CT-13001

Water TouchCell

OTS-CT-13004

Set of O-Rings for TouchCell

SW-C00004-CT

Download Option TouchCell

License for data download