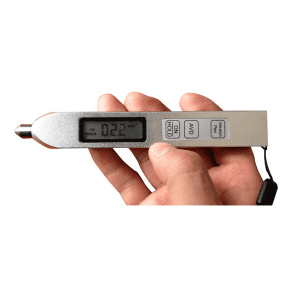

TI-25MXT Thru-Paint Ultrasonic Wall Thickness Gauge

The new CHECK-LINE TI-25MXT Wall Thickness Gauge accurately measures wall thickness and the extent of corrosion of all metals, ceramics, glass and most rigid plastics from one side. When operated in E-E Mode (Thru-Paint Mode), the coating is eliminated from the reading and the gauge will display only the thickness of the metal wall.

TI-25MXT Features include Automatic or Manual Probe Zero maximizing accuracy, 5-position Gain Adjustment to help located the correct backwall echo and to penetrate the walls on sound-attenuating materials such as cast metals and thick materials. It also features Differential mode, Hi-Low Alarms with audible and visual indicators and Scan mode that captures the minimum thickness at 100 measurements per second (100 Hz). It also includes a special Velocity Mode to measure in terms of velocity for nodularity testing.

The gauge and probe have a protection rating of IP67, is impact-resistant and environmentally sealed to provide trouble-free operation under the toughest field conditions The TI-25MXT can be used with any of the following hi-damped dual-element transducers specifically designed for use with E-E Thru-Paint Mode.

Measuring Range on Steel (with standard T-102-2700 probe)

Pulse-Echo (PE) Mode (Pit & Flaw Detection) – 0.040 to 8.00 inches / 1.00 to 199.9mm

Echo-Echo (EE) Mode (Through Paint & Coatings) – 0.100 to 1.000 inch / 2.54 to 25.40 mm

Total Measuring Range (Probe Dependant)

Pulse-Echo (PE) Mode (Pit & Flaw Detection) – 0.025 to 36.000 inches / 0.63 to 914.4 mm

Echo-Echo (EE) Mode (Through Paint & Coatings) – 0.100 to 1.000 inch / 2.54 to 25.40 mm

Features

- Includes NIST Traceable Calibration Certificate

- Includes both Pulse-Echo Mode (Pit & Flaw Detection) and Echo-Echo Mode (Through Paint & Coatings Mode)

- Using the standard probe T-102-2700, the gauge will read thru 0.040″ coating thickness (1 mm)

- Using one of the optional probes T-104-2700, the gauge will read thru 0.075″ coating thickness (1.9 mm)

- Calibrate to a sample of known thickness which automatically calculates the optimal acoustic velocity

- 2-Point Calibration to optimize linearity over a wide measurement range, automatically calculates the optimal acoustic velocity

- Scan mode, 100 readings/sec. Probe is slid over a large measuring area, the minimum thickness during the “scan” will be displayed

- Adjustable GAIN in 5 steps to fine tune the gauge for use on challenging materials or applications

- Differential mode, Hi-Low Alarms with audible and visual indicators

- User-selected Manual or Auto Zero of Transducer

- The extruded aluminum housing is impact-resistant and environmentally sealed (IP 65)

to provide trouble-free operation under the toughest field conditions - Special-purpose probes are offered for a variety of applications (1 to 10 MHz)

- Selectable Backlight ON/OFF/AUTO

- Resolution of 0.001 inch (0.01 mm)

Measuring Limits

| Minimum Radius for Convex Surfaces | 0.350″ (8.89 mm) |

| Minimum Radius for Concave Surfaces | 3″ (76.2 mm) |

| Minimum Headroom | 1″ (25.0 mm) |

| Minimum Sample Diameter | 0.150″ (3.8 mm) |

| Minimum Substrate Thickness – F | na |

| Minimum Substrate Thickness – NFe | na |

Specifications

| Range in Steel | Pulse-Echo Mode (Pit & Flaw Detection) measures from 0.025 to 19.999 inches (0.63 to 500 millimeters) Echo-Echo Mode (Through Paint & Coatings) measures from 0.100 to 1.000 inch (2.54 to 25.40 millimeters) (range depends upon probe selected) – five probes to choose from |

| Resolution | 0.001 inch (0.01 mm) |

| Velocity Range | 0.0120 to .7300 in/μs. 305 to 18,542 meters/sec |

| Probe (Standard) | 1/4″, 5 MHz Hi-Damp Dual Element Transducer, actual wearface is 5/8″ (17mm), p/n T-102-2700 |

| Probes (optional) | 1 to 10 MHz, 3/16″ up to 1 inch (custom probes available) |

| Probe Wearface | PEEK (Polyethylethylkytone) |

| Cable | 1.2m (4ft.) waterproof cable with non-polarized, quick-disconnect connectors |

| LCD Display | Multi-function 7 segment 4.5 digit liquid crystal display with 0.500″ digit height. Two 0.125 in14 segment fields for labels and values, and one 7 segment field for labels and values. Additional icons to indicate features and modes |

| Display Backlight | Backlight is selectable on/off/auto, and selectable brightness (Lo, Med, Hi) options |

| Display Update Rate | 10 Hz (10 updates/sec) |

| Temp. Limits | Ambient: -30 to 75° C (-22 to 167° F) Material: -20 to 100° C (0 to 200° F) High temperature probes available |

| Battery Type | 2x AA batteries (rechargeable batteries can be used) |

| Battery Life | 45 hours continuous use |

| Weight | 308 grams (11 ounces) |

| Dimensions | 63.5 x 131.3 x 31.5 mm (2.5″ x 5.17″ x 1.25″) |

| Accessories | Probe/cable assembly, 4 oz. bottle of coupling fluid, NIST Calibration Certificate, 2 AA batteries, operating instructions, hard-plastic carrying case. |

| Housing | Extruded aluminum body with nickel-plated aluminum end caps (gasket sealed) |

| Housing Rating | IP65 |

| Certifications | NIST Traceable and MIL-STD-45662A |

| Keypad | Sealed membrane that is resistant to both water and petroleum products Seven or eight tactile-feedback keys |

| Pulse Repetition Frequency (PRF) | 200 Hz (200 pulses/sec) |

| To Lock Settings | With gauge powered off, press and hold the “+” key while powering on the gauge The LOCK icon will be illuminated on the Display |

| To unLock Settings | With gauge powered off, press and hold the “-” key while powering on the gauge The LOCK icon will turn off |

| GAIN Adjustment | Adjustable GAIN 5-position (VLOW, LOW, MED, HIGH, VHI), in 3dB steps, 40-52dB |

| Time Dependent Gain (TDG) | Used in both pulse-echo (P-E) and Echo-Echo (E-E) modes depending on transducer and frequency selected |

| Measuring Mode | Pulse-Echo (P-E), Echo-Echo (E-E, Thru-Paint Mode), Scan, Differential, Alarm and VX-velocity |

| Pulser | 150 volt square wave pulser |

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set [HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set](https://www.faadtech.co.th/wp-content/uploads/2024/07/HS-AA031-600x600.jpg.webp)