LubeRight

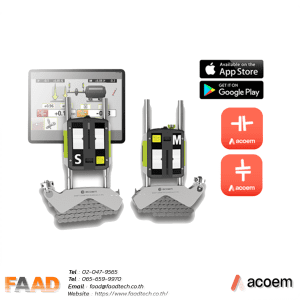

Smart hand lubrication system LubeRight is directly connected and controlled by a computer. It checks and records every round of bearing lubrication with the correct amount of grease as per the manufacturer's specifications, which helps extend the lifespan of bearings. All historical data is stored for future reference.

Each bearing has a stainless steel grease fitting with an embedded signal code (RFID). The chips have unique identifiers, allowing the system to identify the lubrication points of each bearing.

Once the lubrication round is completed, the communication equipment and charger are connected to the grease meter, which is then connected to the computer to download the recorded data. Any missed lubrication points will be highlighted, and bearings that receive excess or insufficient grease will be recorded.

It can be seen that in businesses, there are multiple points where lubricating oil is used for machinery, just as it is essential to prevent machinery from running dry. Over-lubrication, however, is also an erroneous practice. Currently, these lubrication processes are carried out either automatically or manually. With automatic systems, the required amount of lubricating oil can be precisely adjusted. Hence, when utilizing such systems, it is known which points receive lubrication and in what quantity. However, this level of precision is not achievable with manual systems. In manual systems, it becomes necessary to keep a record of which points received lubrication, how much lubricating oil was applied, and when it was applied. Sometimes, excessive lubrication may occur, while other points may be overlooked due to human error.”With the computer-aided manual lubrication systems of Assalub, which specializes in lubrication, all of these problems are eliminated. In this system, which is used together with a computer program, a nipple is mounted at each lubrication point and this point is introduced to the program for once. During this introduction to the computer, the lubrication point is displayed in a group and the number of days and/or how many grams of grease to be applied to this point is entered into the program. In the next step, the lubrication schedule is created by the computer program. Nipples (transponders) have unique numbers defined by the greasemeter. They consist of a hardening plate and an acid-proof steel locking ring. The lubricating nipple is zinc plated. That is, when the person who will lubricate takes the grease gun and goes to the lubrication points in the business, the nipples will be recognized by the antenna grease gun and the lubrication amount (if it is the lubrication day) will appear on the digital greasemeter. If it is not the lubrication day yet The number zero (0) will appear on the greasemeter. That is, when lubricating oil is applied, the counter will count backwards and will not allow any errors. The predefined name of the lubrication point and the required amount of lubricating oil will be displayed on the screen. The amount of lubricating oil fed to the lubrication point is also recorded by the greasemeter. When lubrication is completed that day, a connection will be established between the computer and the greasemeter, and the information will be entered into the computer program. Thus, it will be possible to track how many grams of lubricating oil are applied to which points, which points are skipped, and which points are lubricated even though it is not the scheduled time. During this installation, the program will automatically notify the greasemeter of the next lubrication. The lubricating oil is transferred from the greasemeter to the computer, and it can be easily tracked which points are lubricated or not, how much, and when they are lubricated.

Step 1 : Install

Install the 'LUBERIGHT®' software on the computer. The program management involves data related to each lubrication point, such as name, group, lubricant quantity, lubrication frequency, and job number for that round. Each lubrication point is connected to a specific signal code slot. Then, install the grease fitting along with the signal code slot on the bearing. At this point, the system is ready for use

Step 2 : How to use

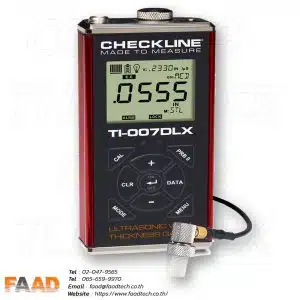

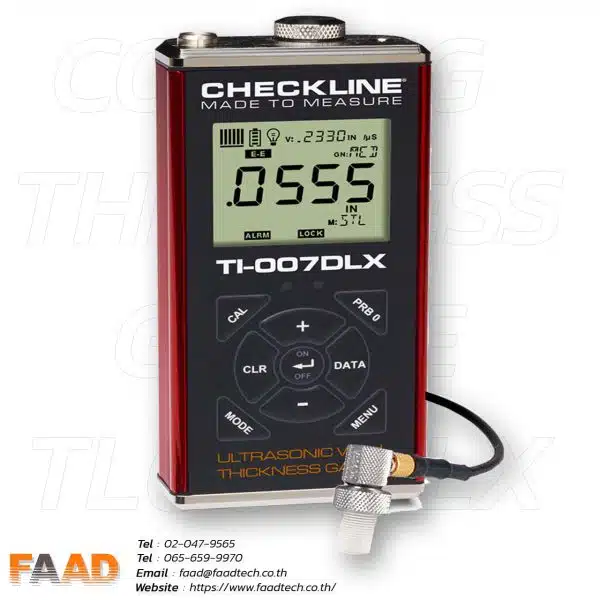

To start a lubrication round, connect the communication equipment and charger of the grease meter to the computer. Then, download the program for the scheduled lubrication round to the grease meter. When connecting the grease meter's grease fitting to the lubrication point's fitting, the grease meter will identify the point's name and advise the operator on how much grease needs to be applied at that point

Step 3 : Report

When the lubrication round is completed, connect the communication equipment and charger of the grease meter to the computer and transfer the data to the software. Once the data transfer is completed, all completed lubrication tasks will be displayed in green, including clear indications of any incomplete tasks

Electric grease gun Ecolube : E890

Electric grease gun Ecolube : E889

Smart hand lubrication system | LUBERIGHT

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.