Belt drive alignment

The Precision Alignment Tool (PAT) ensures you won’t waste time dealing with misaligned belt drives or encountering issues. By using it as a reference mark, you’ll receive precise alignment, reducing belt wear and tear significantly.

Pulley & Belt Laser alignment

Pulley & Belt alignment | PAT 2

PAT – the final solution to all your belt alignment needs!

The Pulley Alignment Tool (PAT) is a device used to adjust the position of belts and inspect the alignment of pulleys in drive systems, such as machinery or equipment that utilize pulleys and belts. Proper pulley alignment is crucial as it affects the overall efficiency of the system and reduces potential damage to the machinery.

Laser Belt Alignment Tool

The Acoem PAT a dual-beam laser transmitter: comes with two line lasers. These lasers emit visible red light to aid in visibility and facilitate the assessment of pulley alignment, making it easier to see and evaluate the positioning of pulleys

Spring-Loaded Guides: Each laser transmitter is equipped with two spring-loaded guides. These guides are designed to attach to the pulley grooves, ensuring precise alignment by securely fitting against the pulleys.

Locking Legs in Various Sizes: The tool comes with interchangeable locking legs in different sizes to accommodate various standard pulley groove sizes ranging from A to E, typically with centerline distances between 6mm to 40mm. This feature enables the Acoem PAT to be adjustable and compatible with different pulley alignment setups.

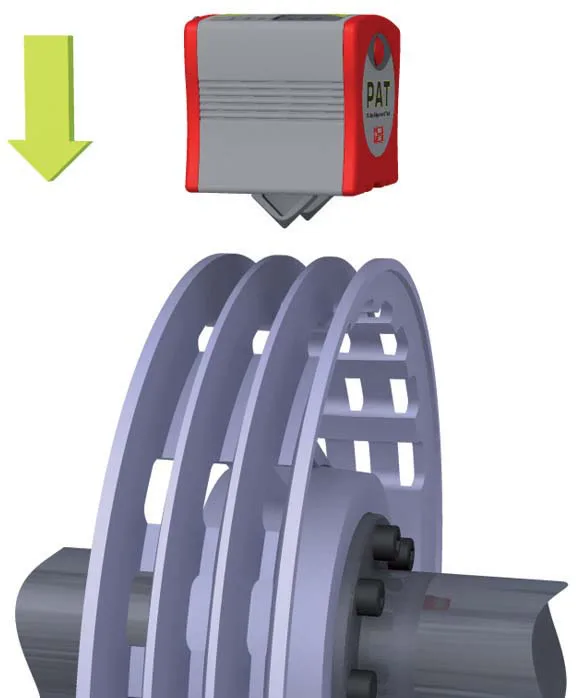

Fixturlaser PAT is easily installed onto pulleys. The spring-loaded probing device locates the center of the belt groove, while magnetic feet are precisely engineered to attach to the pulleys. These magnetic feet install snugly and without gaps, ensuring quick and straightforward installation with optimal positioning accuracy.

How to use

The easily visible red laser light makes it easy to identify the position of your belt-driven machinery.

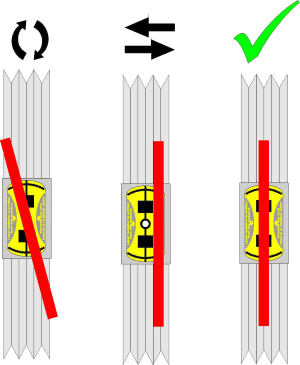

The belt alignment process is as easy as the installation steps. Simply turn on the laser and check the alignment of the unit mounted on the opposite side. The laser will project a line down onto the target perpendicular to the unit mounted across. If necessary, adjust your machinery's position until the laser line aligns with the center mark of both units.

Technical specifications

| PAT – package with case* | |

|---|---|

| Weight (incl. all standard parts): | 1,5 kg (3,3 lbs) |

| Storage Temperature: | -20 to 70°C (-4 to 158°F) |

| Case | |

|---|---|

| Material: | High Impact ABS Plastic |

| Sealing: | Dust, water (5m/16 feet), and air tight with air pressure compensation valve |

| Drop Test: | 3 m (10 feet) on to concrete floor |

| Dimensions: | 250 x 180 x 80 mm (9,84 x 7,09 x 3,15 inch) |

| Measuring units | |

|---|---|

| Housing Material: | Extruded aluminum (molded PA cover) |

| Operating Temp: | 0 to 40°C (32 to 104°F) |

| Relative Humidity: | 10 – 90% |

| Weight: | 340 g (12 oz) |

| Dimensions: | 61 x 77 x 61 mm (2,4 x 3 x 2,4 in) |

| Environmental Protection: | IP 65 |

| Laser: | 630 – 675 nm class II diode laser |

| Laser Line Fan Angle: | 90° |

| Laser Power: | < 1 mW |

| Measurement Distance: | 50 mm – 6000 mm (1,97 – 236,22 in) |

| Measurement Accuracy: | Better than 0,5 m (0,02 in) or 0,2 degrees |

| Pulley Diameter Range: | From 75 mm (2,95 in) and larger (standard) |

| Pulley Belt Groove Width: | 6 mm – 40 mm (0,23 – 1,57 in) (standard) |

| Power Supply: | 2 pcs of LR03 (AAA)1,5 V per unit |

| Operating time: | 20 hours of continuous operation |

| Laser Safety: |  |

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set [HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set](https://www.faadtech.co.th/wp-content/uploads/2024/07/HS-AA031-600x600.jpg.webp)