PRODUCT DETAIL :

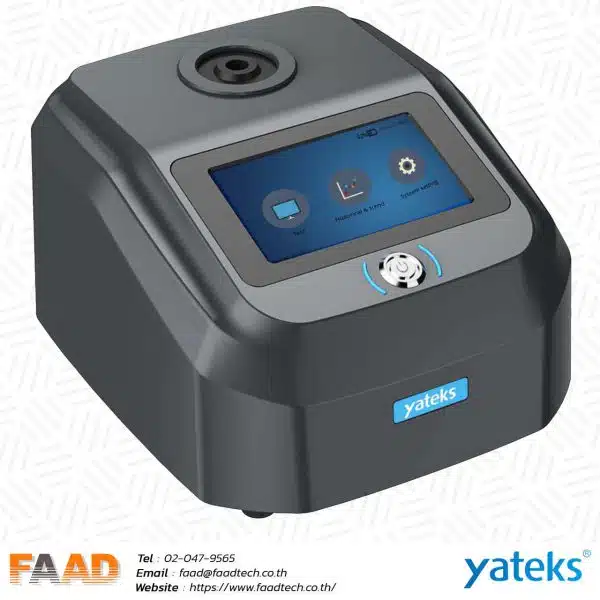

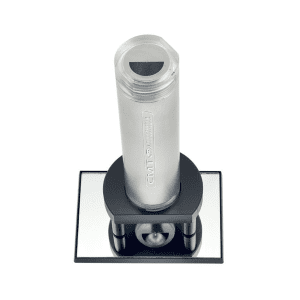

Online monitoring sensor Viscosity and Density YTS31 applies the world advanced piezoelectric resonant MEMS components. With the internal integration of high-precision signal sampling and processing unit as well as the advanced algorithm, it can automatically provide real-time fluid density, viscosity and temperature data. The 20 ℃ density, kinematic viscosity, viscosity index and viscosity of 40 ℃ and 100 ℃ can also be acquired through the interior powerful calculating program.

YTS31 3-in-1 oil condition sensor is easy to use and requires no operator intervention. All tests are done automatically by the sensor. The user can simply install it on the pipe to measure the density, viscosity, and temperature through the productive process.

Features :

- Capable of achieving accurate measurements of the viscosity, density and temperature of up to 8 parameters with the imported probe and interior powerful algorithm analysis.

- The density measurement accuracy :0.001g / cm3, viscosity measurement range:0.3~400mPa·s, measurement accuracy: 2%, temperature measurement range:-40~120℃.

- Fast response, data refresh rate for only 1s.

- Stainless steel material, excellent resistance to chemical corrosion and stress characteristics.

- Measurement is not affected by external vibration, suitable for online monitoring of robustness requirement.

- Effective service life of more than 10 years, none moving parts and consumable parts.

- Compact structure, fit for system integration.

- CE, ASTM1657 and other certifications and testing standards.

Specification :

| MEASUREMENT INDICATORS | DENSITY(KG/M³),DYNAMIC VISCOSITY (MPA·S),TEMPERATURE (℃) |

|---|---|

| Optional Indicators | Kinematic viscosity, 40°C viscosity, 100°C viscosity, viscosity index, 20°C density |

| Measurement Range | Density 0.6 g/cm³~1.3 g/cm³ or 600 kg/ m³~1250 kg/ m³ Viscosity 25~400mPa·s(500mm²/s) Temperature 0℃~100℃ |

| Measurement Accuracy(typical @23℃) | Density 2% or 3 kg/ m³ Viscosity 5% or 1 mPa·s (the larger value) Temperature 0.3℃ |

| Resolution | Density 0.0001g/cm3 or 0.1 k/.m3 Viscosity 0.1mPa·s Temperature 0.1℃ |

| Response Time | < 30 seconds (for the first time), data re fresh once per second |

| Digital Output | RS485 MODBUS RTU (RS232 optional) |

| Analog Output | 4~20 mA, resistive load <500Ω. (optional) |

| Alarm node | 2 channels 250VAC/3A or 30VDC/3A (optional DDU350) |

| Working Voltage | DC 9V‐32V |

| Power Consumption | < 30mA@24Vdc RS485 |

| Probe Pressure Range | max 10 bar |

| Fluid Temperature | 0℃~ 100℃ |

| Environment Temperature | ‐40℃~ 85℃ |

| Material | 316 stainless steel Hastelloy |

| Structure Size | φ32×57 mm |

| Weight | 360g |

| IP Rating | IP66 |

| Cable Jumper | M8;6pin; 2 meters |

| Max Flow Velocity | ≤ 0.3 m/s |

| Standard | CE certification, ASTM1657, EN61326‐1、 EN61326‐2‐3, ICES‐003 B. |

Application :

Online monitoring sensor Viscosity and Density YTS31 is widely applied to online monitor the viscosity and density of lubricating oil, hydraulic oil, gear oil, gasoline, diesel oil, jet fuel, kerosene, biodiesel, ethanol, chemical reagent and coating ink.

Online monitoring sensor Viscosity and Density YS31 is applied to food processing, laboratory, fuel oil storage and transportation ; Oil refining, wind power and other power industries; Aviation, navigation, railway and other transportation industry;Drilling platform and other maritime engineer, mechanical engineering equipment,transportation vehicle,fuel storage and transportation vehicle, oil handling equipment, chemical test and analysis,oil handling and filter system; Coating, painting and other printing industry, medical equipment,etc.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.