ACOEM : Laser shaft alignment AT400

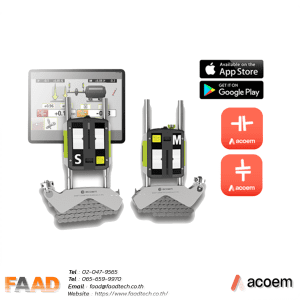

Laser shaft alignment AT400

Maximize machinery performance with our 2-axis shaft alignment tool. Achieve precise alignment, minimize vibration, and extend equipment lifespan

- Unleash productivity and efficiency with advanced sensors and precise 2-axis measurement, delivering superior results across diverse applications.

- Intuitive and user-friendly interface for simplified navigation and an enhanced user experience.

- Introducing the market’s thinnest 2-axis sensor, weighing 306 g. With a 20-meter measurement range, it revolutionizes precision applications with its compact design and exceptional accuracy.

The large detector features a 20×20 mm2 size and offers a high-resolution of 0.001 mm, making it ideal for precise position sensing and different measurement applications.

Feature : Laser Shaft alignment AT 400

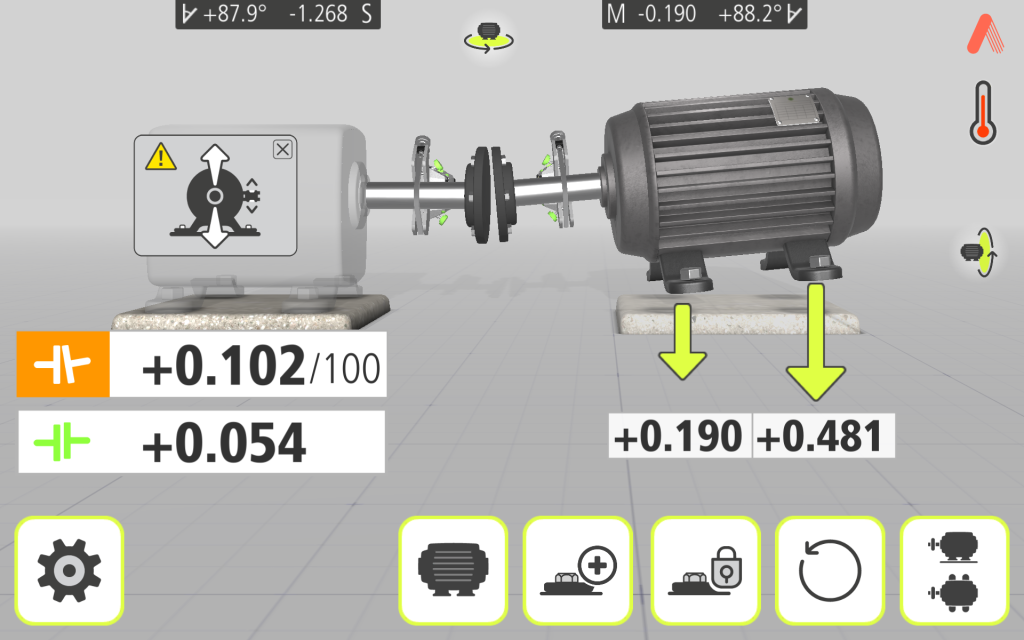

SoftCheck™

Easily verify the presence of soft foot with the SoftCheck™ feature to make a reliable alignment

Softfoot : is the state of the machine on all 4 sides are not at the same level caused by the legs or stands that are damaged or worn by use Come to learn more easily from the VDO clip.

Target values

Easily control the temperature of the machine. with cold and hot lines Target values

FeetLock™

Get better automatic guidance for a base-bound or bolt-bound situation with the FeetLock™ function

Spacer Shaft Function

The spacer shaft function is used when the alignment is performed on machinery using membrane coupling.

Multiple Feet

Some machines have more than two pairs of feet. To perform proper alignment in these cases, the Multiple Feet function comes handy

VertiZontal™

Align machines in horizontal and vertical direction in only one move with Acoem VertiZontal™ feature and save time

Measuring methods.

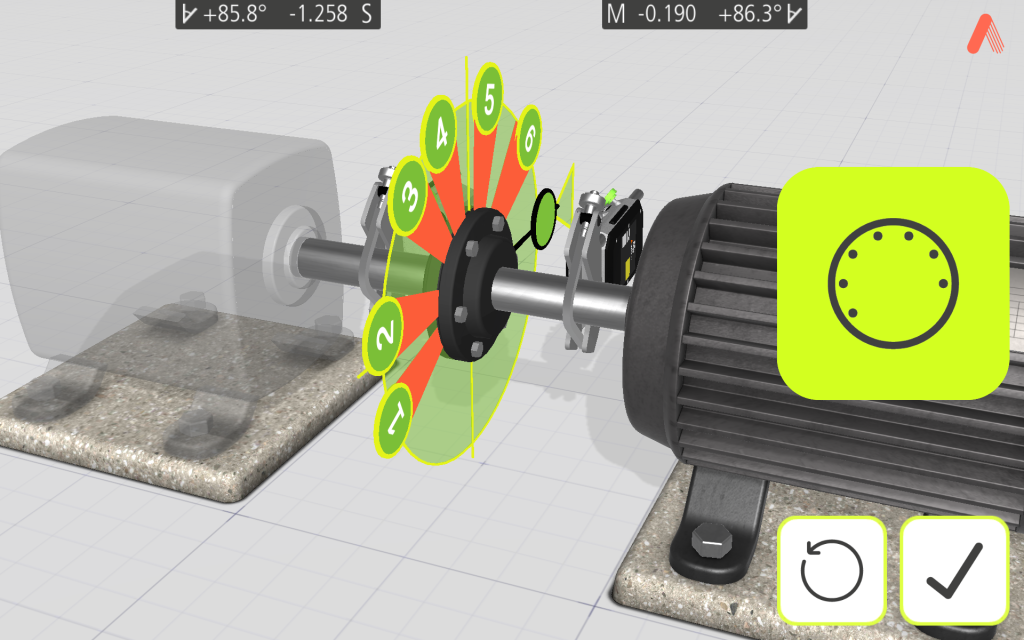

Tripoint™ method

In the Tripoint method, the alignment condition can be calculated by taking three points while rotating the shaft at least 60°. In this method, all points are taken manually.

TRIPOINT Express™ method

This method seamlessly incorporates the Tripoint approach, offering the added advantage of fully automated measurements throughout the process.

Clock™ method

Clock™ In the Clock method, machinery positions are calculated by taking three points with 180° of rotation.

Multipoint method

This function enables measurement initiation from any position on the rotation, allowing recording of multiple points for optimized calculations. Ideal for turbine and sliding bearing applications.

Multipoint Express method

Our method follows the classic Multipoint method approach, but with the advantage of automated measurements for greater convenience.

GuideU™,

Effortlessly navigate through our user-friendly interface, GuideU™, designed to make it a breeze to follow and understand.

True Live™

Get the position of both the shafts in real time with Acoem True Live™ feature

PDF EXPORT

Once the measurement is finished, you can generate a comprehensive PDF report that includes graphs and measurement data, providing detailed documentation of the measurement object.

Camera

Take pictures of your machines and setup to illustrate automatically in the report

Sync

Centralize and share your reports with your team, consolidate your plant’s alignment status, and assign alignment workorders to team members.

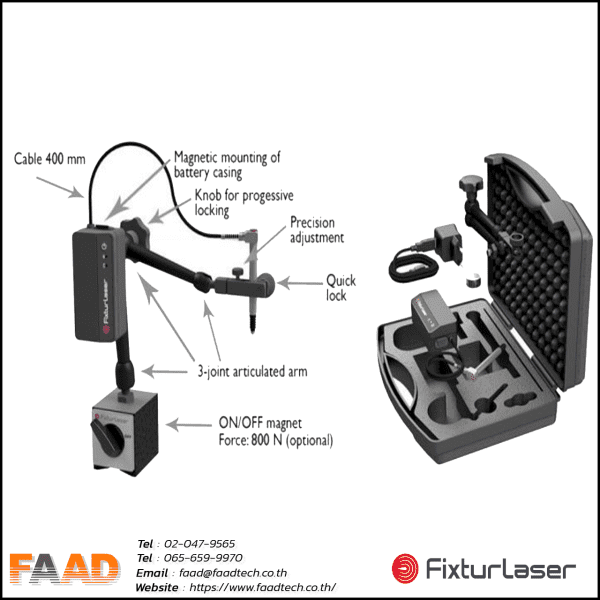

Packaging & Deliverables

Laser shaft alignment : AT-400

Each ACOEM AT-400 D is delivered with the following package:

• Acoem M9

• Acoem S9

• Acoem AT DU

• Rod kit

• Magnetic base ON-OFF

• Extension fixture 49mm

• Chain 8 mm 60 links (L=970 mm)

• Magnetic v-bracket 2

• Tape measure 5 m

• Acoem usb

• V-bracket complete 2

• Angled universal tool 2

• USB-cable A-mini B 2m

• Power supply 4 USB-ports 5 VDC

• Quick Guide AT

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.