Rapid screening of oil samples for ferrous wear debris using a PQ Index instrument has become an established method in most used oil laboratories. It is a brilliant wear indication and provides even further information if seen in relation to other elementary analysis methods.

There are several sources for iron wear particles in lubricants or grease such as scratched surfaces, erosion or broken parts. Often the particles are larger than 5 microns which is a size which will not be detected by laboratory methods like ICP (Inductively Coupled Plasma).

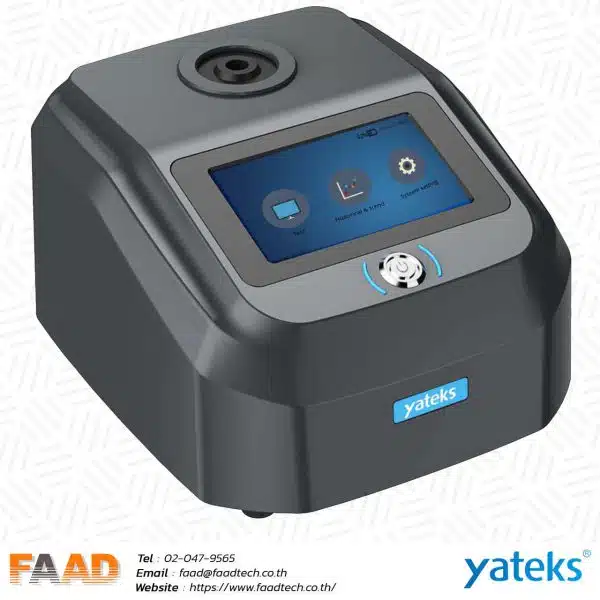

A high PQ index often indicates a serious wear problem which causes large particles to appear in the sample. The device measures all ferrous particles in a sample regardless of the size. Its innovative sensor and data processing guarantee a good stability and high sensitivity.

The instrument´s standard USB connection can be used to transfer data directly into an existing LIMS system. The FPQ has been designed to work with standard 100 ml sample bottles. This allows to take the measurement without having to transfer the sample to another specialized container. The device can also be used with standard 2 ml grease pots. Adapters for different sample vessels are available on request.

Ordering Information

OTK-CT-11224

FPQ Ferrous Debris Monitor

| Range: | 0 – 15000 PQ |

| Repeatability: | +/- 5 PQ for < 500 PQ |

| 1% for results > 500 PQ | |

| Power supply: | 230 V DC (50/60 Hz) |

| Test time: | 10 seconds |

| Dimensions: | 430 x 380 x 155 mm |

| Weight: | 7.5 kg |

SAM-CT-70288

100 ml Sample Bottles, (288)

| Neck: | 38 mm |

| Material: | PETG |

SAM-CT-70289

100 ml Sample Bottles, (288)

| Neck: | 38 mm |

| Material: | HDPE |