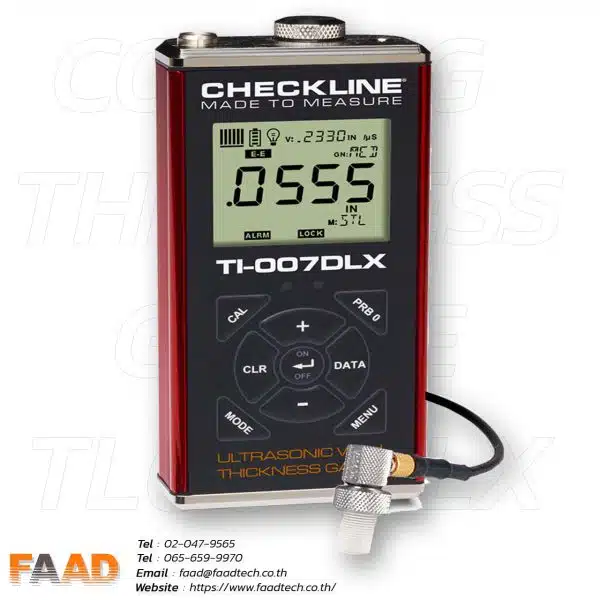

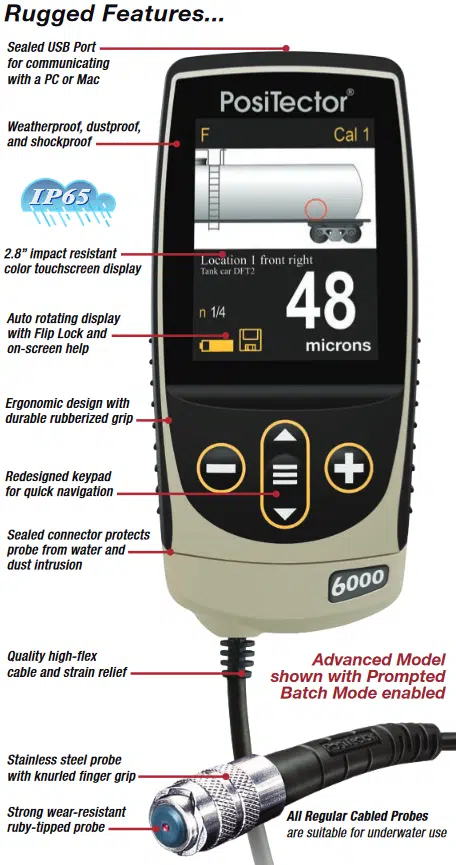

Coating Thickness Gages : Positector 6000

The 6000 Series Coating Thickness Gauge is a precise and rugged, coating thickness gauges that use magnetic and eddy current principles to measure coating thickness on both ferrous and non-ferrous metals, accurately and quickly. No calibration adjustment is required for most applications.

The Positector’s 2.8″ impact-resistant color touchscreen features a redesigned keypad for quick menu navigation. An IP65-rated enclosure is watherproof, dustproof, and water-resistant. The probe has a wear resistant ruby probe tip, for long-lasting calibration.

USB, WiFi, and Bluetooth connectivity to PosiSoft PC, Mac, and Smartphone software . Conforms to ISO 2178/2360/2808, ISO 19840, ASTM B244/B499/D1186/D1400/D7091/E376/G12, BS3900-C5, SSPC-PA2, US Navy NAVSEA PPI 63101-000, US Navy NAVSEA 009-32, AS 2331.1.4, AS3894.3-B, and other standards.

Features

Easy-To-Use

- Ready to measure—no calibration adjustment required for most applications

- Enhanced one-handed menu navigation

- Flashing display—ideal in a noisy environment

- RESET feature instantly restores factory settings

Durable

- Solvent, acid, oil, water and dust resistant – weatherproof

- Wear-resistant probe tip

- Shock-absorbing, protective rubber holster with belt clip

- Two year warranty on gage body AND probe

Accurate

- Certificate of Calibration showing traceability to NIST or PTB included (Long Form)

- Built-in temperature compensation ensures measurement accuracy

- Hi-RES mode increases displayed resolution for use on applications that require greater precision

- Conforms to national and international standards including ISO and ASTM

Versatile

- Fully interchangeable probes are compatible with ALL gage bodies

- Multiple Calibration adjustment options including 1 point, 2 point, known thickness, average zero

- Selectable display languages

- Hi Contrast backlit display for bright or dark environments

- Flip display enables right-side-up viewing

- Extended cables available (up to 75 m/250 ft) for underwater or remote measuring

- Uses alkaline or rechargeable batteries (built-in charger)

Feature Comparison Chart

| Feature Comparison Chart | Standard (1) | Advanced (3) |

|---|---|---|

| 2.8” impact resistant color touchscreen with redesigned keypad for quick menu navigation |  |  |

| Fast measurement speed—60+ readings per minute. Enhanced FAST mode – 90+ readings per minute for quick inspection. | ✔ | ✔ |

| SCAN Mode – take continuous readings without lifting the probe | – | ✔ |

| Hi-Lo limits audibly and visibly alerts when measurements exceed your specified limits | ✔ | ✔ |

| Multiple stored calibration adjustments for measuring on a variety of substrate conditions | – | ✔ |

| Reading Storage Capacity | 1000 in one group | 250,000 in up to 1000 batches and sub batches |

| SSPC PA2 feature set determines if film thickness over a large area conforms to user-specified min/max levels | – | ✔ |

| PSPC 90/10 feature determines if a coating system complies with an IMO performance standard for protective coatings | – | ✔ |

| Onscreen help, real time graphing, picture prompting and batch notes | – | ✔ |

| Multiple stored calibration adjustments for measuring on a variety of substrate conditions | – | ✔ |

| Wireless Technology for data transfer to a PC or optional portable printer | – | ✔ |

Specifications

| Measuring principle: | magnetic induction principle (Ferrous) eddy-current principle (Non-Ferrous) |

| Surface Temp. | Maximum 120 °F / 49 °C |

| Power | 3 AAA batteries, Included |

| Dimensions | 5″ x 2.6″ x 1″ (127 x 66 x 25.4 mm) |

| Weight | 4.9 oz. (137 g) without batteries |

| Protection Class | Meets or exceeds IP5X, Solvent, acid, oil, water & dust resistant |

| Warranty | 2 Years |

| Min. Concave Radius | 1 inch (2″ OD) |

| Standards | Conforms to ISO 2178/2360/2808, PrEN ISO 19840, ASTM B499/D1186/ D1400/D7091/E376/G12, BS3900-C5, SSPC-PA2 and others |

| Probe Cable Length | 3 ft (1 meter) |

| Nickel-Plating | Nickel-plating with a phosphorus content of 8% or greater makes it a “non-magnetic” coating (typically Electroless Nickel Plating – EN) and it can be measured using a Ferrous probe. |

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.