Particle Pal Pro

The picture of health

Our all new NEW Particle Pal Pro utilises new digital imaging technology which provides greater insight into the size and type of particulate in any oil system. Air bubble elimination and shape recognition gives root cause particle analysis. Remaining oil life and water content sensors complete the package.

A vision of the future

Harnessing the power of proven digital imaging technology

We've embedded the latest in particle counting technology into our new Particle Pal Pro series. Giving ISO 4406 counts as well as 4, 6, 14, 21, 38, 70 & >100 micron sizing and bubble elimination. Digital imaging combined with advanced algorithms sorts particles into fatigue wear, cutting wear and sliding wear categories to give root cause analysis.

This powerful technology, when coupled with additional sensors for measuring water content and oil life, gives unprecedented on the spot insight into the condition of your oil.

Three models are available, each feature:

- Particle counts using the new Atten 2 counter: ISO 4406, SAE & NAS

- Broader spectrum of micron sizing – 4, 6, 14, 21, 38, 70 and >100 micron

- Shape recognition in the software to categorise:

- Fatigue wear

- Sliding wear

- Cutting wear

- Fibres

In addition, the second model features:

Water content as % saturation (%RH – Relative Humidity)

The third model also features:

Oil life determination utilising Tan Delta's oil condition sensor

Database of over 500 oils

Ability to self profile an oil to add to the database

Other options

- A high-pressure option of every model is also available

Particulate analysis.

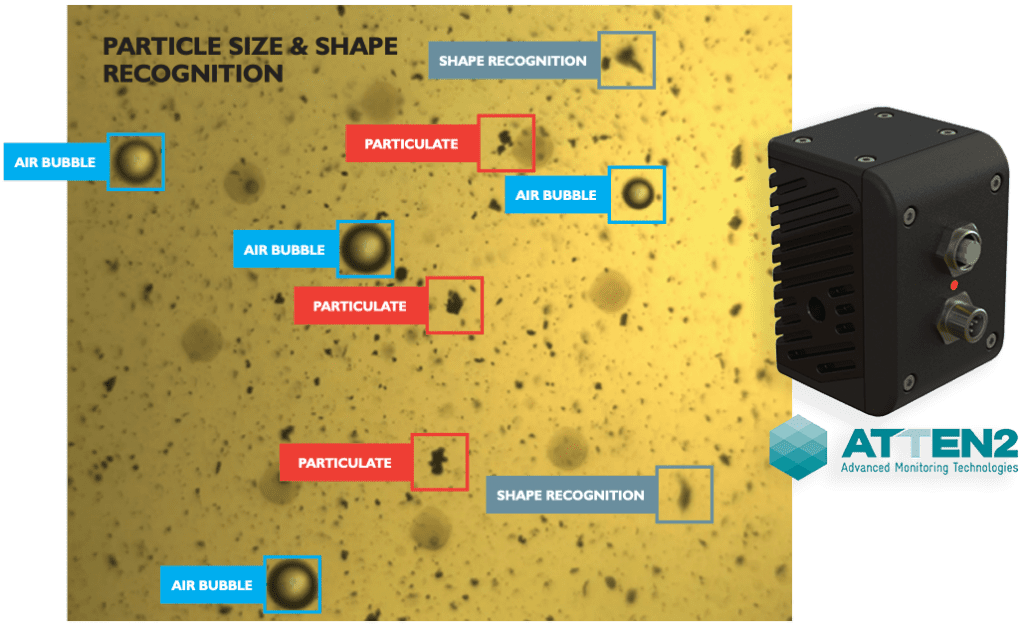

The Atten2 digital imaging particle counter gives advanced size and shape recognition for any sample. Counting particulate in virtually any oil up to 2,400cSt, the Atten2 device also eliminates air bubbles, making it ideal for heavy lube and gear oil applications in cold temperatures. Reporting 4, 6, 14, 21, 38, 70 & >100 micron counts as well as categorising any particle greater than 20 microns into: • Fatigue Wear; • Sliding Wear; • Cutting Wear; • Fibres;

Digital Image Particulate Counter

Capable of broad size determination from 4, 6, 14, 21, 38, 70 >100 micron counts. Air bubble and water droplet elimination. Shape determination to identify fatigue, sliding or cutting wear as well as fibre identification.

Spider Infographic

A multi-stage infographic helps engineers understand at a glance the condition of their oil, based on all of the data collected from the internal sensors.

Water Sensor

Water in oil is a contaminant that can contribute to microbial growth and encourage further contamination, from solids to rust. The inbuilt water sensor shows the relative humidity of any oil as a % saturation.

Battery Life

Internal rechargeable lithium batteries provide a long life for remote use.

Oil life sensor

The Tan Delta Full Spectrum Holistic oil condition sensor monitors the overall condition of the oil, giving you unparalleled sensitivity, accuracy and precision. This enables the oil’s remaining useful life to be calculated. The sensor works with virtually any oil, drawing on a database of over 500 common industrial oils with the ability to self-calibrate.

NEW Software

A 10” touch screen LCD allows users to view data in great detail, with zoom, trending and analysis breakdown. Within the software we have embedded oil ageing profiles for over 500 oils. Also included is the ability to self-calibrate an oil life profile, should your oil not be on the database. This is a one time routine where oil is taken through a heat cycle.

Internal Stepper Motor Pump

We’ve developed a fully controllable stepper motor driven pump to deliver exact flow rates for any oil, from 1 to 2,400 cSt. The pump also allows connection to a live system up to 350bar via a high pressure adaptor.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.