Wireless Vibration Sensor Triaxial

WIreless Vibration Sensor | Acoem Sparrow

Sparrow Sets You Free.

Vibration Sensors : Sparrow Enhance the capabilities of the industry by improving the efficiency of data analysis in dangerous and hard-to-access positions, as well as the importance of Reactive maintenance. Utilize wireless vibration sensors like Sparrow to gather real-time in-depth information about your BoP. These assets aid in making proactive decisions and improving the performance and preventing damage to your machinery.

No longer worry about unexpected breakdowns or unforeseen malfunctions. Empower yourself with Sparrow’s intelligent intervention and enter into reliable and sustainable investments. Step beyond the limitations of the past and embrace a world of smooth inspections, efficiency, and accessibility for everyone. As we integrate advanced sensors into our environmental system for Total Plant reliability, Sparrow paves the way for a brighter, smarter, and more interconnected future.

You can use it together with You can get all other products from ACOEM which will complement the system. Acoem Advisor

Features

FLEXIBLE SOFTWARE & HOSTING PLATFORM

FLEXIBLE SOFTWARE & HOSTING PLATFORM

Connect all your data-collecting tools on one software platform with either on-premises or cloud-based storage. Seamless big data integration lets you easily link your machine health information with your data lake via OPC UA (Nesti4.0, Gateway), Modbus TCP (Gateway) or MQTT (Gateway).

COMPACT, DURABLE & EFFORTLESS DEPLOYMENT

COMPACT, DURABLE & EFFORTLESS DEPLOYMENT

At only 33mm high, the Sparrow sensor can be deployed anywhere. Dust, water and solvent-resistant for greater longevity. Operational in ambient conditions of -40 °C to +80 °C. Simple and straightforward to install and operate with your precision data available within minutes.

24/7 ACCESS TO ACTIONABLE DATA

24/7 ACCESS TO ACTIONABLE DATA

Simplifies your decision-making process and enhance your operational efficiency with information from every machine in your network available in one place at any time thanks to the Acoem WebPortal.

LOW COST OF OWNERSHIP

LOW COST OF OWNERSHIP

As the Acoem reliability range’s entry-level solution, Sparrow makes monitoring more affordable, especially for large-scale projects. Standard replaceable battery extends your sensor’s lifecycle, meaning no technology redundancy.

ADVANCED DIAGNOSTICS CAPABILITIES

ADVANCED DIAGNOSTICS CAPABILITIES

With the benefit of the Acoem Machine Health Matrix & Shock Finder™ Filter, quickly assess the health of your machines with professional vibration analysis data available on a single screen on any enabled, secure device. Access displays of shocks in the time waveform automatically.

ACCESS TO EXPERTISE

ACCESS TO EXPERTISE

Remote support via our Acoem Advisor service whenever needed. An individually tailored, custom-designed condition-based maintenance program can be developed with data analysis and certified reports from Acoem experts worldwide.

Compatible with NEST4 predictive maintenance program.

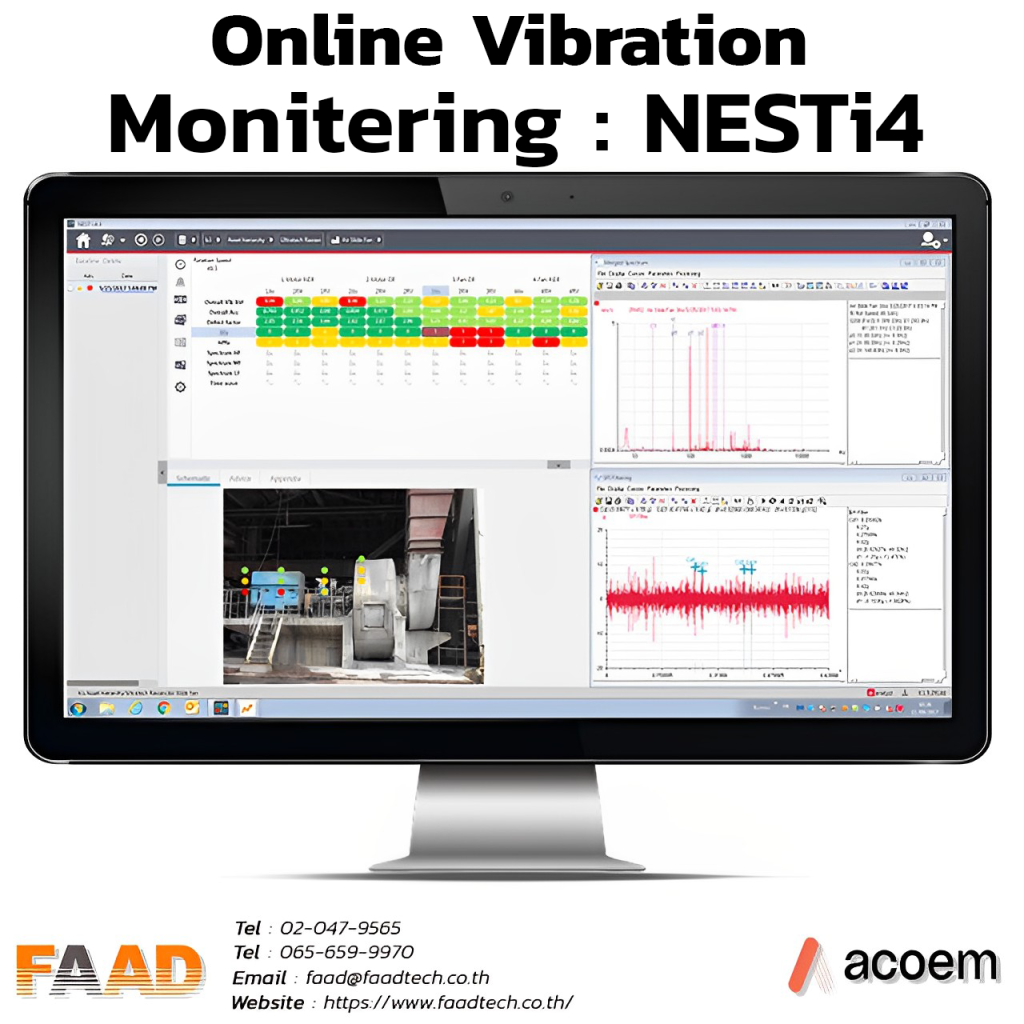

Wireless Vibration Sensor : Sparrow Provide important information to relevant machine maintenance personnel. Concise and easy to use, Nesti4.0 will be a program that will help you in your work. and collect data Necessary for Sparrow

NESTi4.0 NESTi4.0 is a new generation of monitoring software. Designed to help you take advantage of the best of Industry 4.0, accessible and easy to use with internationally patented artificial intelligence AI (Accurex).

Whether you are a beginner or technical expert, NESTi4.0 helps put accurate vibration analysis and condition monitoring in everyone’s hands.

- Providing a comprehensive maintenance team that works efficiently through diagnostic tools, saving time and resources.

- Reducing the complexity of decision-making processes by presenting all machine data in one place

- Accessing actionable data 24/7

- Installation of machinery: Vibration Sensor Sparrow, displaying accurate and straightforward information that is easy to understand.”

- There is a program called Machine Health Matrix that checks the health of your machinery quickly and efficiently using a single screen.

- The Shock Finder™ Filter displays the impact in the form of wave patterns over time.

- Smooth integration of large-scale data: Easily link your machinery’s health data with your Big Data system environment.

Sparrow | Expert analysis & Health Matrix

Expert Graphical analysis tool:

- Analysis cursors (single, dual, …)

- Frequency measurement, Bearing

- Peak extraction markers (1X, 2X, 3X…)

- Logarithmic or linear display

- Acceleration/Velocity/Displacement switch

- Post processing: Shock finder, TW filter, …

Machine Health Matrix

Machine Health Matrix

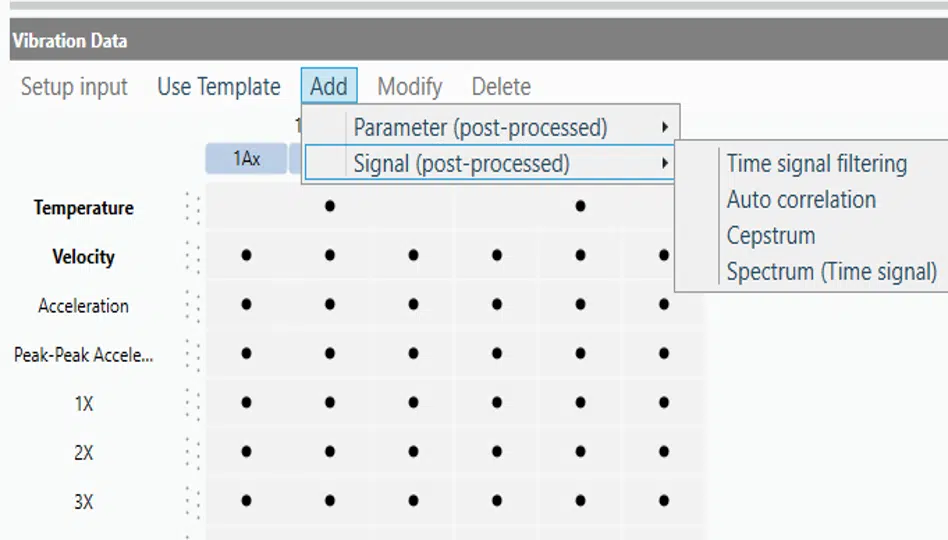

Sparrow | Unique Post Processing capabilities

Expert Graphical analysis tool:

- Analysis cursors (single, dual, …)

- วัดความถี่ ตลับลูกปืน

- Peak extraction markers (1X, 2X, 3X…)

- Logarithmic or linear display

- Acceleration/Velocity/Displacement switch

- Post processing: Shock finder, TW filter, …

Description

Number of axes: 3-axis (adjustable sensor orientation)

Dynamic range: ±8 / ±16 / ±32 g, (configurable)

Nominal frequency range (@ 25,600 Hz SF):

Fmax: 10kHz

Sensing resolution: 240 μg

(X, Y, Z)

Spectral noise (10 Hz): 630 μg√Hz

Resolution lines: 12,800 (25,600 in single axis mode)

Sampling frequency: 200Hz to 25.6 kHz

Smart sensor: Overall velocity, temperature, time waveform

Acquisition modes: Smart interval, alarm-based

Size and weight: Ø47 mm, 33mm high, 186 grams

Case material: Stainless steel, ABS

Mounting: ¼-28 UNF thread

Sealing: IP69

Operating ambient: -40 to 80 °C (40 to 176 ºF) temperature Note that extreme temperatures reduce optimum battery life

Solvent resistance: Common solvents resistant,

Compliances: CE, RoHS, Reach, contains FCC ID: X8WBT840F

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.