What is Ultrasonic Leak Detector

What is Ultrasonic ?

Ultrasonic is an oscillation of a frequency greater than the upper limit of the human vocal range, that is, more than about 20 kilohertz.

The term sonic is applied to very high amplitude ultrasound waves. Hypersound, sometimes called praetersound or microsound, is a sound wave with a frequency greater than 1,013 hertz. At such high frequencies It is very difficult for sound waves to propagate efficiently. In fact, at frequencies above approximately 1.25 × 1013 hertz, it is impossible for longitudinal waves to propagate at all. even in liquids or solids This is because the molecules of the material in which the wave is traveling cannot pass through the vibrations.

Table of frequencies that living things can listen to

| Animal | Frequency. (hertz) | |

|---|---|---|

| Lower | Higher | |

| Human | 20 | 20,000 |

| Cat | 100 | 32,000 |

| Dog | 40 | 46,000 |

| Horse | 31 | 40,000 |

| Elephant | 16 | 12,000 |

| Animal family: cow, bull | 16 | 40,000 |

| Bat | 1,000 | 150,000 |

| Animal family: grasshopper, cricket | 100 | 50,000 |

| Rodents, rats, beavers | 1,000 | 100,000 |

| Animal family: whale, dolphin | 70 | 150,000 |

Examples of sound sources

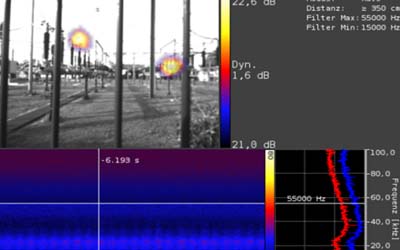

Ultrasound detector It is a machine that can detect the sound source of the said phenomenon. The machine will heterodyne high-frequency sound waves into frequencies that humans can hear to make it easier for inspectors to work.

Examples of sound sources

Ultrasound Inspection

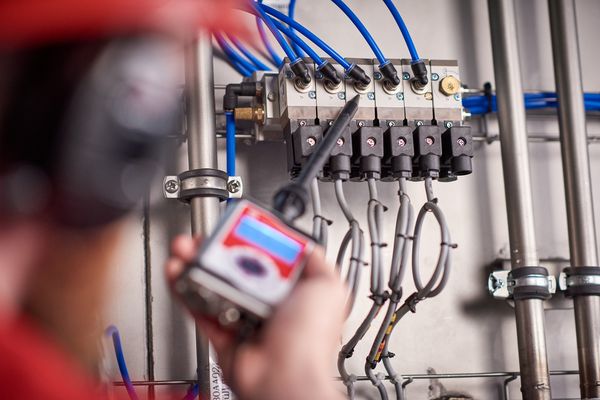

Inspection with an ultrasound sound wave detector (Ultrasound Inspection)

Before getting to know the tool, you must first know what ultrasound sound is? Ultrasonic sound waves are sound waves with frequencies higher than the range that humans can hear. It is a high frequency sound wave. but low energy short wavelength They tend to move in straight lines and are easily absorbed by energy. And there are three causes of ultrasound sound waves in factories: Friction, Impact, and Turbulence.

Inspection with an ultrasound sound wave detector (Ultrasound Inspection)

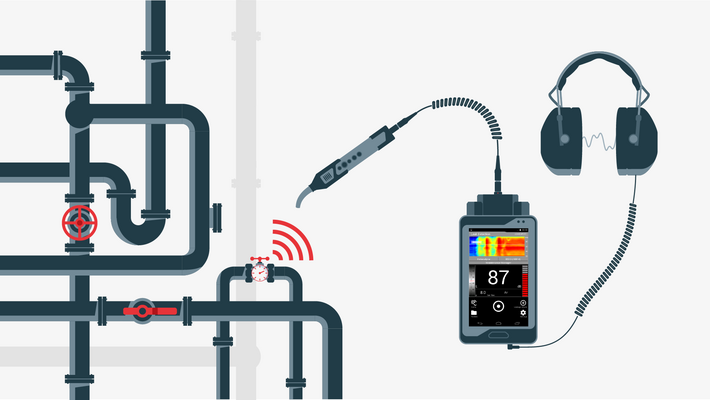

Producing compressed air is a costly process. And loss of compressed air as a result of leaks worsens system performance. and cause unnecessary expenses

Our ultrasonic detector SONAPHONE and SONOASCREEN camera can detect leaks easily and quickly. Can be used with both compressed air systems , inert gas systems and vacuum systems

Using the Sonaphone and SonaScreen

Thickness Gauge inspection machine SONAPHONE® T & SONOSPHERE

Leak Detecter : SONAPHONE Pocket

Ultrasonic leak detector

in compressed air, inert gas and vacuum systems

Today, energy saving is an important topic in all areas that use compressed air. Finding and fixing leaks in a compressed air system alone can save up to 35 percent in compressor-related energy costs. Regular ultrasonic inspections and preventive maintenance also help increase efficiency. reliability in the use of machinery and equipment as well

Advantages of ultrasonic leak detection

- Detects leaks in compressed air, inert gas, and vacuum systems.

- Can help reduce energy consumption of compressed air systems by up to 35%.

- Patent pending for classifying leaks and estimating leak levels in liters per minute.

- LeakExpert: Dedicated app for leak detection and classification for SONAPHONE.

- Able to create a leak report

LEAKEXPERT

Specific app for leak detection and classification

Leak Detectors

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.