What is Reliability Centered Maintenance

The Meaning of Reliability Centered Maintenance

Reliability Centered Maintenance (RCM) is a process for planning and executing maintenance activities with a focus on enhancing the reliability of equipment and machinery. It involves analyzing potential failures and their impacts. The primary goal of RCM is to identify and prioritize maintenance tasks to ensure that machinery and systems can operate as intended efficiently and effectively.

In an era where technology and machinery play a crucial role in production processes and operations, effective maintenance management and minimizing the risk of disruptions have become essential. One of the widely adopted and proven approaches is Reliability Centered Maintenance (RCM).

Benefits of Reliability Centered Maintenance (RCM):

01

Downtime and Production Loss

- Improved Equipment Uptime and Availability

Enhances the operational time and availability of machinery. - Reduced Unplanned Downtime

Minimizes unexpected stoppages, ensuring smoother operations. - Decreased Machinery Damage

Lowers the likelihood of severe equipment failures.

- Improved Equipment Uptime and Availability

Early problem detection helps prevent unplanned downtime, reducing production disruptions and associated losses.

02

Enhanced Safety for Workers and Assets

- Prevention of Hazardous Conditions

Scheduled maintenance helps prevent dangerous situations, creating a safer working environment. - Accident Prevention

Reduces the risk of accidents caused by machinery failures.

- Prevention of Hazardous Conditions

In summary, RCM not only improves operational efficiency but also significantly reduces risks to workers and assets, contributing to a safer and more reliable workplace.

03

Maintenance costs

- Optimized maintenance schedules

- Avoidance of catastrophic failures

- Extended asset lifespan

Proactive care and timely interventions extend the lifespan of equipment.

04

Energy savings

- Improved efficiency

- Process optimization

- Machine optimization

In summary, RCM helps reduce energy consumption by ensuring machinery operates at peak efficiency and minimizes energy loss caused by damage or system malfunctions.

Case Study 1

Case study : Paper Machine

Downtime is the largest source of lost production time for most manufacturers

Downtime Section 2

- Planned downtime for scheduled asset maintenance and

- Unplanned downtime due to equipment failure and human error.

Shutdowns, scheduled or not, can eat up to 1%-10% of available production time

Impact of Reducing Downtime :

- Reducing downtime by just 1% can increase profits by 4.7% to 8.2%.

Energy Costs in the Paper Manufacturing Industry::

- Energy costs account for 25%–30% of total production expenses.

- Unplanned downtime of a single paper production machine can cost more than $20,000 (approximately 700,000 THB) per minute.

- In cases where a paper mill experiences unplanned production stoppages, the losses can reach up to $1 million (approximately 35 million THB) per day.

Tools and Techniques Used in the RCM Process

Tools and Techniques Used in the RCM Process Various tools and techniques are employed in RCM to ensure thorough and efficient analysis. Key methods include:

- Failure Modes and Effects Analysis (FMEA): Used to evaluate potential consequences of failures within a system.

- Root Cause Analysis (RCA): Identifies the primary causes of issues and ensures corrective actions address the root problems effectively.

- Criticality Analysis: Prioritizes machinery or equipment based on their importance and the severity of potential failure consequences.

- Condition Monitoring Tools: Tools such asVibration analysis, Thermal imaging, and Ultrasound are used to detect and prevent equipment malfunctions.

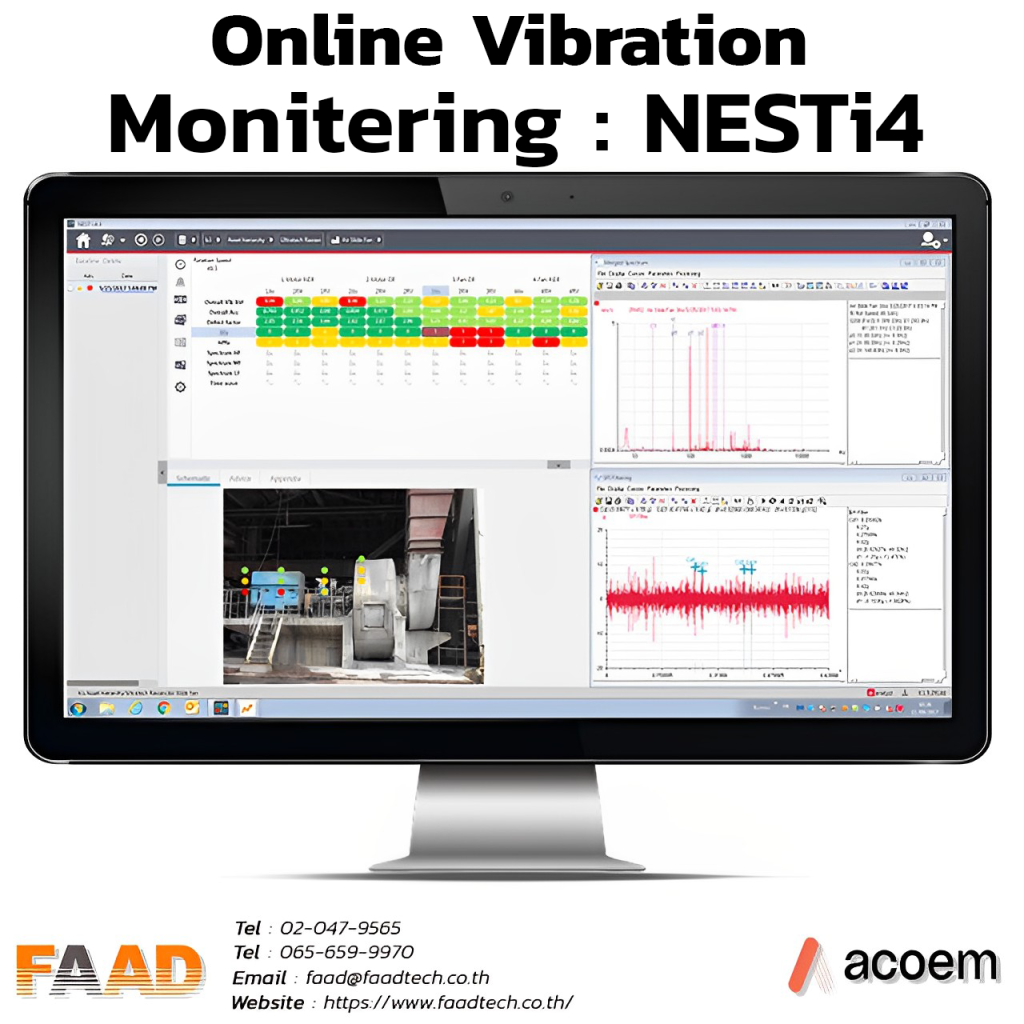

- Reliability Data Analysis: Software tools equipped with AI, such as Nesti4, are utilized for in-depth problem analysis, including 3-axis measurements and diagnostics of various machinery issues.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.