What is Machine Maintenance?

Maintenance machine

Machine maintenance is a critical process in preserving the efficiency and lifespan of machinery to ensure maximum performance and allocate a maintenance budget appropriate for the specific usage of each machine. Maintenance tasks vary from regular daily upkeep to repairs when machinery encounters issues or malfunctions. Therefore, machine maintenance is beneficial in multiple aspects.

Types of Machine Maintenance

The types of machine maintenance can be categorized into 4 types:

- Breakdown Maintenance (Repairing damaged parts)

- Planned/Preventive Maintenance (Scheduled maintenance)

- Predictive Maintenance (Anticipating maintenance needs)

- Proactive Maintenance (Addressing root causes of issues, a modern approach)

Breakdown Maintenance

Breakdown Maintenance : also known as repairing damaged parts when machinery or equipment breaks down, is a maintenance method used to address issues immediately after they occur, without prior planning or formal scheduling. When machinery or equipment experiences a problem, breakdown maintenance involves repairing it promptly to restore functionality in a short period. This approach focuses on sufficient repairs while the machine is still in operation.

The advantage of breakdown maintenance :

- Quick problem resolution: Since repairs are carried out immediately after an incident occurs, it helps reduce the downtime of the machinery.

- Minimized damage: Addressing issues while they are still minor or before they escalate significantly may help minimize long-term damage.

Preventive Maintenance

Preventive maintenance is a process of scheduled care and repairs aimed at reducing damage or potential issues that may arise with machinery or equipment. It focuses on strengthening and maintaining the condition of machinery to mitigate the impact of unexpected breakdowns and minimize damage or downtime caused by failures or malfunctions.

This maintenance approach increases the likelihood of machinery or equipment operating more efficiently and reduces the damage or expenses incurred from repairs due to unforeseen problems.

The benefits of preventive maintenance include:

- Reduced risk of problems: Regular inspection and maintenance of machinery help reduce the risk of problems or damage.

- Increased efficiency: Machinery that receives regular maintenance often operates more efficiently and conserves energy.

Predictive maintenance

Predictive maintenance is a process that utilizes data collection and analysis to predict when machinery or equipment is likely to fail or encounter problems. It employs various technologies and devices such as sensors, information systems, and machine learning to monitor signals or operational systems of machinery to anticipate future failures or issues. This helps in efficiently planning maintenance activities, reducing machine downtime, and saving costs on repairs.

The advantages of predictive maintenance include:

- Appropriate maintenance planning: Predicting when machinery is likely to fail helps in planning maintenance activities in advance, reducing potential damage from machine downtime.

- Cost savings on maintenance: Conducting maintenance while issues are still minor helps reduce damage and maintenance expenses.

Proactive maintenance

Proactive maintenance is a maintenance strategy that focuses on preventing problems or damage before they occur, rather than waiting for machinery or equipment to fail before taking corrective action and improving efficiency. This method utilizes predictive and historical data of machinery operations to find appropriate prevention methods.

The difference between proactive maintenance and predictive maintenance is that proactive maintenance emphasizes proactive preventive measures, while predictive maintenance focuses on predicting failures and addressing them before they occur.

The benefits of proactive maintenance include:

- Reduced risk of problems: Proactive maintenance helps decrease the risk of issues or damage by initiating actions while the machinery is still in good condition.

- Improved work efficiency: Anticipating potential problems in advance allows machinery or equipment to operate efficiently without interruptions.

Leak Detector Acoustic Imager | Cry Sound CRY2624 is an explosion-proof instrument suitable for petrochemical and heavy-duty industries.

Analytics and Reports

Template-based processing and recording of data, waveforms,spectra,spectrograms is supported by CRYSOUND report analysis tool software, generating ISO 50001 compliant, editable protocols in Excel format.

PD Detection & PD Type Identification

Partial discharges can be detected before more serious faults would occur, even before a thermal camera would detect them.

Vibration Camera Motion Detector – RDI IRIS M™

Live Motion Amplification®

Calibrated Displacement Measurements

Frequency Based Filtering

Advanced Troubleshooting

Motion Amplification®

Up to 1400 FPS in HD Resolution

Calibrated Displacement Measurements

Available as an Add On

Live Motion Amplification®

Multiple Synchronized CamerasContinuous Monitoring

Event and Threshold Triggering

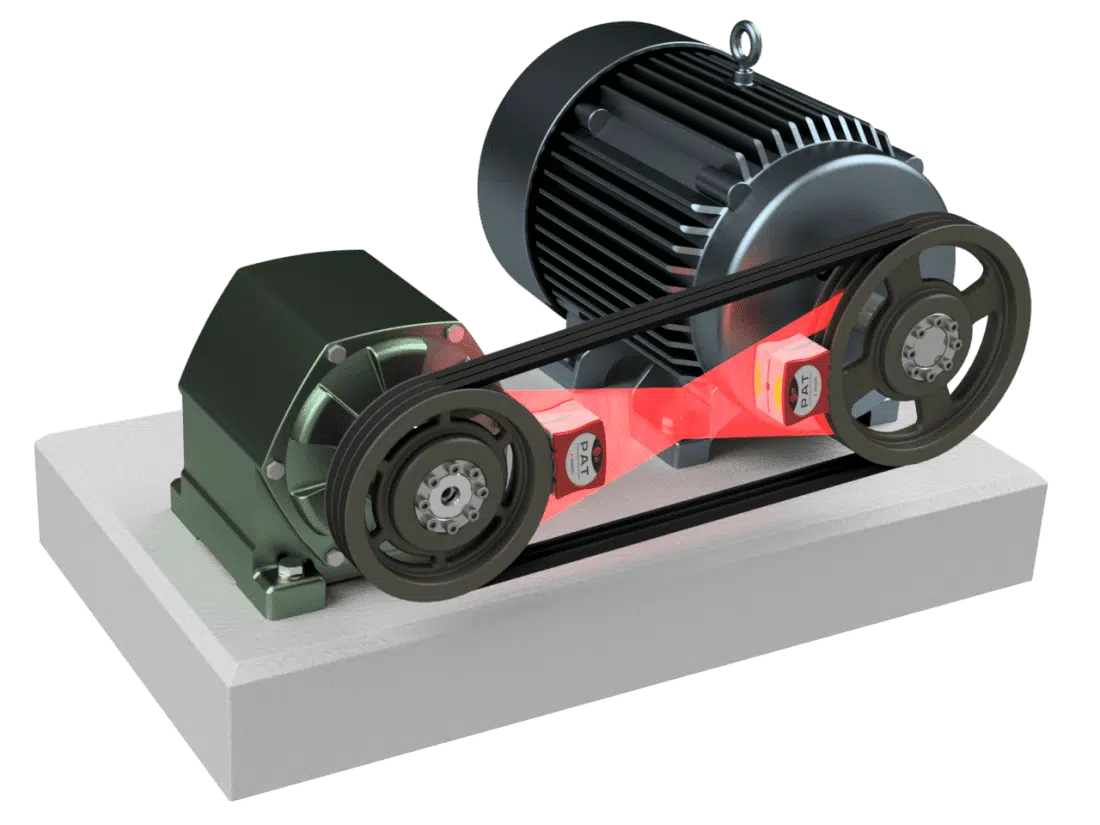

Laser shaft alignment AT400

Innovative 2-axis shaft alignment tool that will create a new standard of precision and efficiency For various shaft alignment applications

- Increase power and enhance standards Productivity and efficiency with advanced sensors and precise 2-axis measurement deliver accurate results.

- Intuitive interface that is easy for ordinary users to understand. Increase the experience for users more satisfied

- Introducing the thinnest 2-axis sensor on the market, weighing 306 grams with a measuring range of 20 meters, revolutionizing high-precision applications.

The large sensing boost sensor measures 20×20 mm and has a high resolution of 0.001 mm, making it suitable for precise position sensing and various measurement applications.

ACOEM : Laser shaft alignment AT400

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.