What are vibration tools and how are they used?

VIBRATION TOOLS : Vibration Tools are essential instruments in various industries, including construction, manufacturing, machinery analysis, and maintenance. Using these tools not only enhances operational efficiency but also helps reduce problems and increase safety in the working process. In this article, we will explore the different types of Vibration Tools and how each type is used.

ประเภทของ Vibration Tools

1. Vibration Meters

- Usage: This type of tool is used to measure the level of vibration in machinery or equipment in various industries to assess operational conditions and prevent potential issues caused by abnormal vibrations.

- How to Use: The user will attach the vibration meter to the machinery or equipment being inspected. The vibration data is displayed on the screen and can be recorded for future analysis.

2. Vibration Analyzers

- Usage: This type of tool is used to analyze and diagnose complex vibration problems, such as detecting imbalances in machinery, checking for bearing wear, or identifying other mechanical issues.

- How to Use: The user needs to connect the analyzer to the machinery and begin collecting vibration data. The collected data is then analyzed using specialized software.

3. Vibration Calibrators

Usage:

- Generate Standard Vibrations: Vibration calibrators generate vibration signals with known frequencies and amplitudes, which can be compared with readings from measurement tools to verify accuracy.

- Verify Accuracy: By comparing the readings from the measurement tool with the standard values generated by the calibrator, you can check whether the measurement tool is accurate as expected.

- How to Use: The user connects the vibration meter to the calibrator and starts the calibration process according to the specified standards.

4. Vibration Isolators

- Usage: These devices are used to reduce or isolate vibrations from machinery to other parts of the system or structure.

- How to Use: Vibration isolation equipment is installed between the machinery and the support base, or at locations where it is necessary to reduce the transmission of vibrations.

Vibration Meter : Falcon

Acoem Falcon

- Features: The Acoem Falcon is a portable vibration meter designed for high-level vibration analysis. It can measure and analyze vibration data within the device itself. It features an easy-to-use touchscreen and supports wireless data recording.

- AI for Analysis: The FALCON enables immediate utilization of condition-based maintenance: the patented Accurex™ automatic diagnosis system operates immediately upon the first measurement. Detected faults are displayed on the device, such as activating user interactions (e.g., bearing lubrication, temperature control) and optimizing maintenance processes.

Online Vibration : MVX

Acoem MVX

- 24/7 Online Monitoring Real-Time Vibration Monitoring

OneProd MVX can monitor machinery vibrations in real-time, 24/7, allowing for immediate detection of anomalies as they occur. - Multiple Sensor Connectivity

It supports connectivity with multiple vibration sensors simultaneously, enabling vibration monitoring from various sources at the same time. - Condition Monitoring

The system can analyze vibration data and use condition monitoring techniques to identify potential issues, such as bearing wear, component imbalance, or other problems that could impact machinery performance. - Automatic Alerts

When anomalies in vibration levels are detected, the system can send alerts via email or messages to responsible personnel, allowing for prompt corrective action.

- 24/7 Online Monitoring Real-Time Vibration Monitoring

Vibration Calibrators: AT2040

This is a tool used for calibrating and verifying the accuracy of vibration measurement instruments, such as sensors or vibration analyzers used in industrial applications. It has specific features that enhance the precision and convenience of calibration, including:

- Wide Measurement Range: The AT2040 can generate vibrations across a range of frequencies and amplitudes, making it suitable for calibrating measurement instruments with different measurement ranges.

- High Accuracy: The device provides high precision in generating vibrations, ensuring reliable calibration and allowing detailed verification of measurement instrument accuracy.

- Sensor Sensitivity Test: It calibrates and checks the condition of vibration sensors, such as Accelerometers or Proximity Probes, and displays the sensitivity values of the sensors in the report.

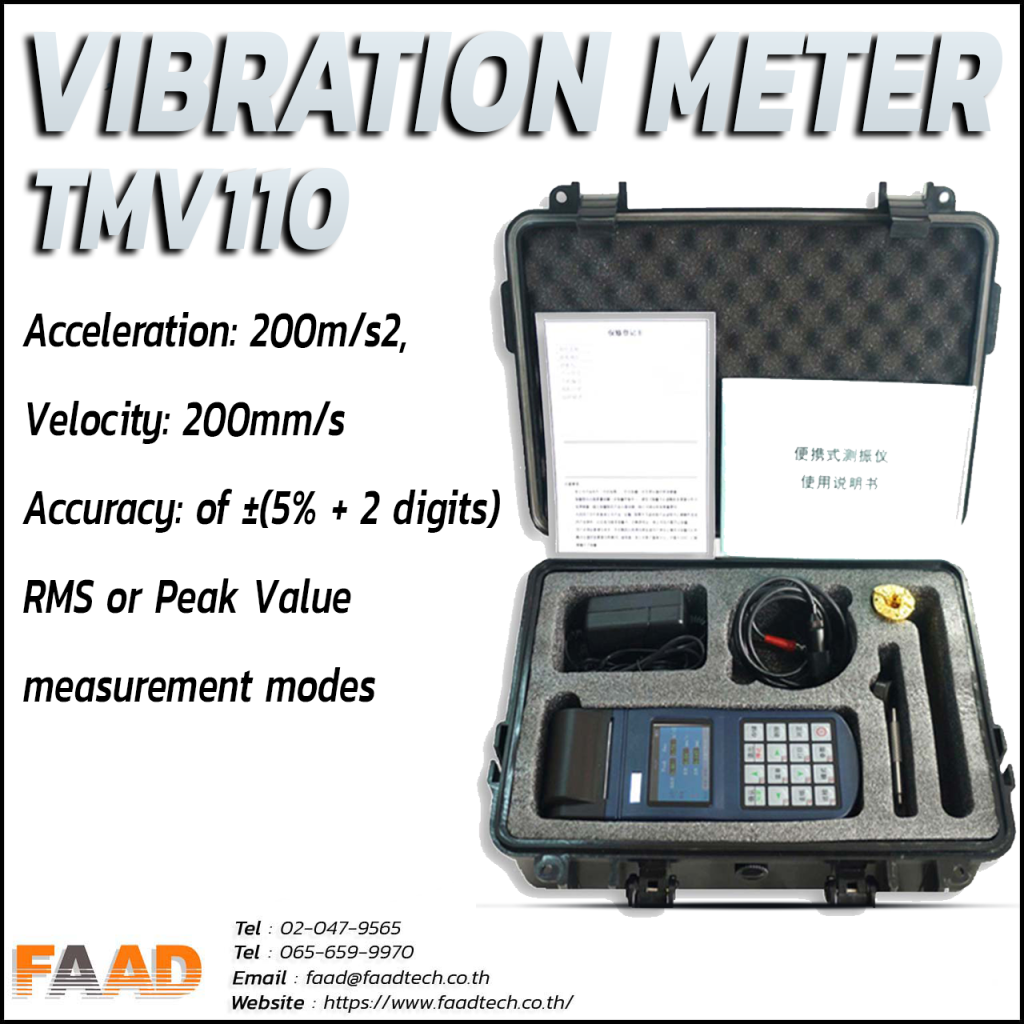

Vibration portable

This vibration meter is used to analyze the input signal. Results include RMS Velocity, peak-peak value, displacement value, Acceleration, or Real-time Spectral.

This vibration meter is used to measure the error. of motors, electric fans, pumps, air compressors machine tools, etc. urgently and quickly

The vibration meter is used for maximum acceleration data. RMS Velocity Data and Displacement Peak-Peak Data Measurement

This vibration meter is used for measuring the error. of motors, electric fans, pumps, air compressors machine tools and others

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.