Laser measurement tool for shaft alignment and geometric applications

With a mix of shaft alignment and geometric measurements, you are safeguarding your machinery’s operation conditions. Regular maintenance checks or installations of new machinery, you have what you need in the NXA Ultimate – the ultimate measurement tool for optimal machine condititions!

Shaft Alignment and Geometric Versatility with the NXA Ultimate

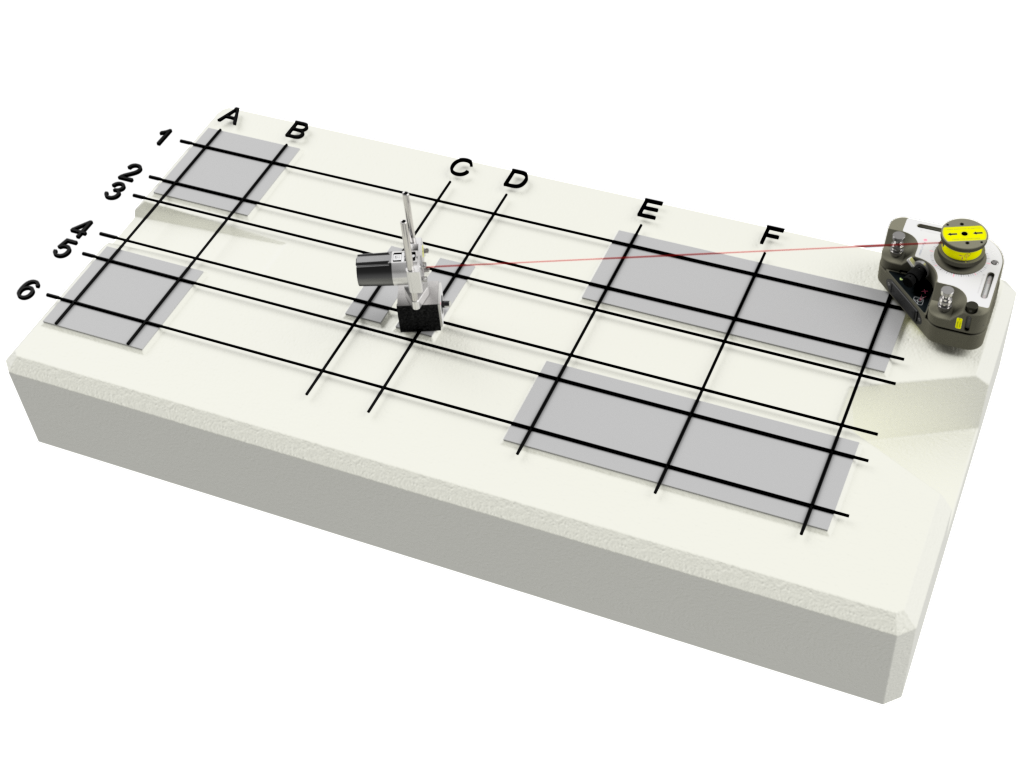

Using geometric measurements in combination with shaft alignment, will allow you to address many of the root causes of outages as part of a complete preventive maintenance program. In the rectangular flatness program e g, you will find it is particularly beneficial to combine such a measurement with shaft alignment when installing rotating machinery. First you check the foundation’s surface for possible irregularities, a so called pre-alignment check. If the foundation is perfectly flat, install the machine and check for possible misalignment with the NXA Ultimate.

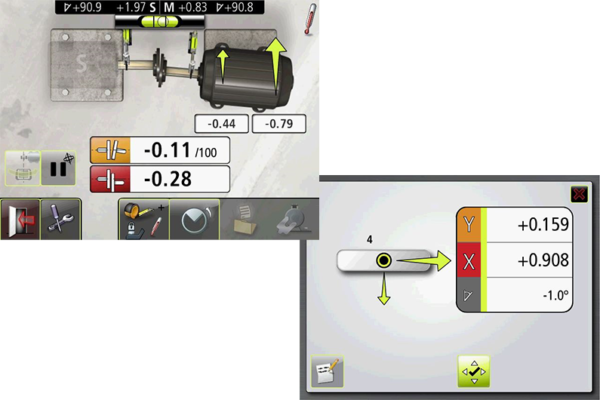

OmniView™ – live screen orientation changes as you move around the machine

The inclusion of a gyroscope in our display box enables the system to track the user’s position in relation to the machine. You will always have the correct live screen orientation of the machine thanks to our industry-first and patented function, the OmniView™.

Geometry with the NXA Ultimate

Using geometric measurements in combination with shaft alignment, will allow you to address many of the root causes of outages as part of a complete preventive maintenance program. In the rectangular flatness program e g, you will find it is particularly beneficial to combine such a measurement with shaft alignment when installing rotating machinery. First you check the foundation’s surface for possible irregularities, a so called pre-alignment check. If the foundation is perfectly flat, install the machine and check for possible misalignment with the NXA Ultimate.

Live adjustment

You always know your machine’s position with the NXA Ultimate! It delivers live values during measurement and simultaneous live adjustment during the adjustment process, with measurement results shown in micron resolution. In the straightness program, adjustments are made live in dual-axis.

Fast on-site evaluation and report of results

On-site evaluation of measurement results means that you can process saved measurement results in order to choose the best reference. This will result in as few corrections as possible. With the feature Best Fit, you have the option to allow the system to calculate a reference line or plane, which illustrates the best fit.

The PDF report function provides you with a fast on site reporting tool for converting saved measurement reports into PDF files.

Rugged design and IP65 certified

All our products are IP 65 which means that the NXA Ultimate is rated as dust tight and is protected against water projected from a nozzle. You can trust the NXA Ultimate in harsh industrial environments!

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set [HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set](https://www.faadtech.co.th/wp-content/uploads/2024/07/HS-AA031-600x600.jpg.webp)

![[ASH456] – HIGH TEMP ACCELEROMETER [ASH456] – HIGH TEMP ACCELEROMETER](https://www.faadtech.co.th/wp-content/uploads/2024/07/dASH456-2-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH214-3A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH214-3A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/06/MH214-3A-3-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH140-1A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH140-1A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/MH140-1A-1-600x600.jpg.webp)

![Magnet Mounting Base with 1/4-28 [MH137-1A] Magnet Mounting Base with 1/4-28 [MH137-1A]](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-MH136-1A-1-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH128-1A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH128-1A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-MH128-1A-2-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH114-3A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH114-3A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-TREA330-2-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH112-1A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH112-1A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-AC192-2-600x600.jpg.webp)

![Magnet Mounting Base with 1/4-28 [MH136-1A] CTC Magnet Mounting Base with 1/4-28 [MH136-1A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-MH136-1A-3-600x600.jpg.webp)

![Magnet Mounting Base with 1/4-2 [MH123-1A] CTC Magnet Mounting Base with 1/4-2 [MH123-1A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-MH123-1A-5-600x600.jpg.webp)

![Magnet Mounting Base with 1/4-28 [MH122-1A] CTC Magnet Mounting Base with 1/4-28 [MH122-1A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/MH122-1A-CTC-1-600x600.jpg.webp)