Offset

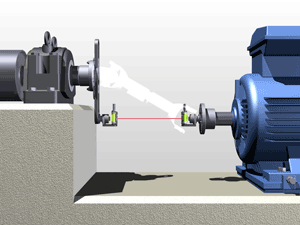

Machines with offset drives are often thought of as insensitive to angular errors between driving and driven shaft. However, they cannot absorb angular misalignment between the shafts, hence our kit the Offset Fixtures. Conventional alignment methods do not provide the required level of accuracy.

Why align cardan shafts?

Cardan shafts with angular misalignment typically cause the driven shaft to rotate unevenly during operation, which results in increased vibration. In other words, it is just as important to align cardan shafts as regular shafts. Why is that?

A vital part in drives for machines, where breakage of cardan shafts causes downtime

Badly aligned cardan shafts set limitation in production capacity and product quality

Stands for a considerable cost when repairs are needed or a breakdown occurs

Badly aligned cardan shafts reduce lifetime in gearboxes and motors

The breakdown of a cardan shaft in running condition could be extremely dangerous.

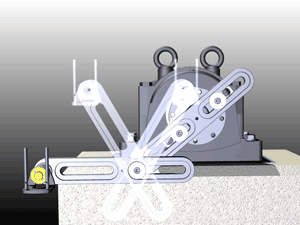

Use the NXA with the Offset Fixture kit and you can precision align any offset mounted machine as fast as you align any other shafts. The Offset Fixture kit consists of both software and fixtures.

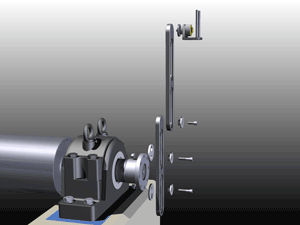

Laser pointer for fast mounting

The Offset fixture is equipped with a laser pointer, which means that the alignment system is not needed in order to mount the fixtures. The fixtures only have to be adjusted until both the lasers are hitting the center of the opposing target. Thanks to this feature, the mounting can be performed fast.

The Offset fixture comes with a number of methods of attachment. The system is designed so you can, in most cases, utilize the coupling bolts themselves when mounting the arm on the flange.

The Offset laser fixture is adjustable in a plane parallel to the flange face of the stationary machine and can be set at any position to eliminate the offset from the driven unit.

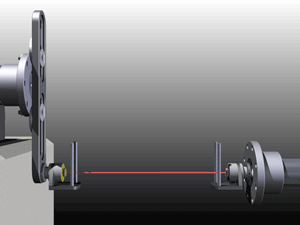

The built-in lasers in each turret are pre-adjusted so the laser beam represents the axis of rotation for the unit, it is mounted on.

The Clock method is used to get the result. In the Clock method, machinery positions are calculated by taking three points with 180 degrees of rotation.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.