Travel Monitor

Introduction

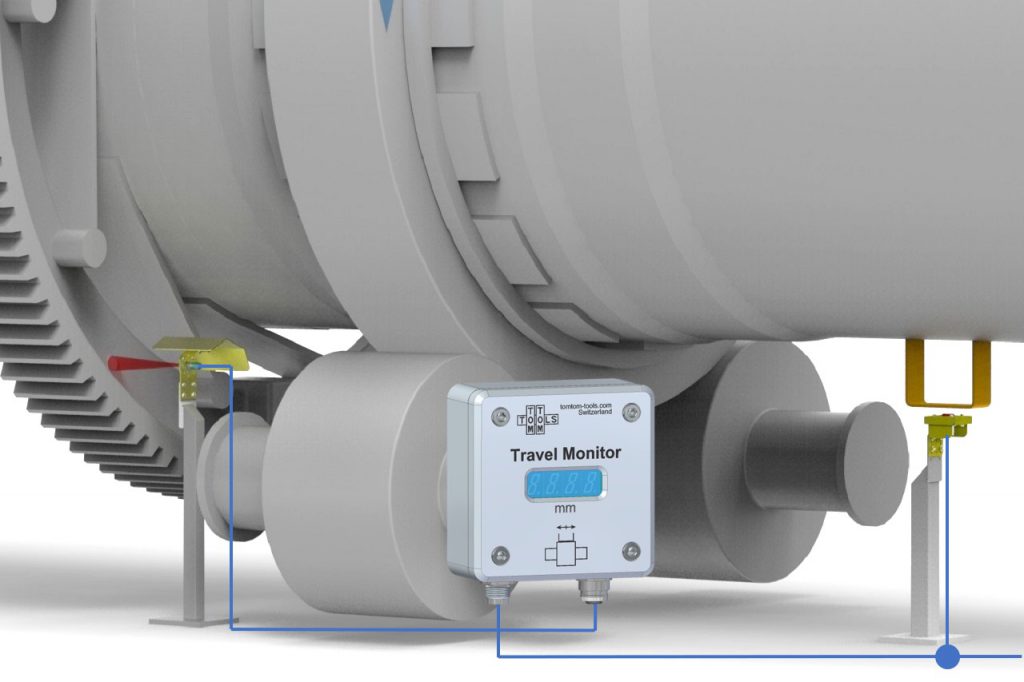

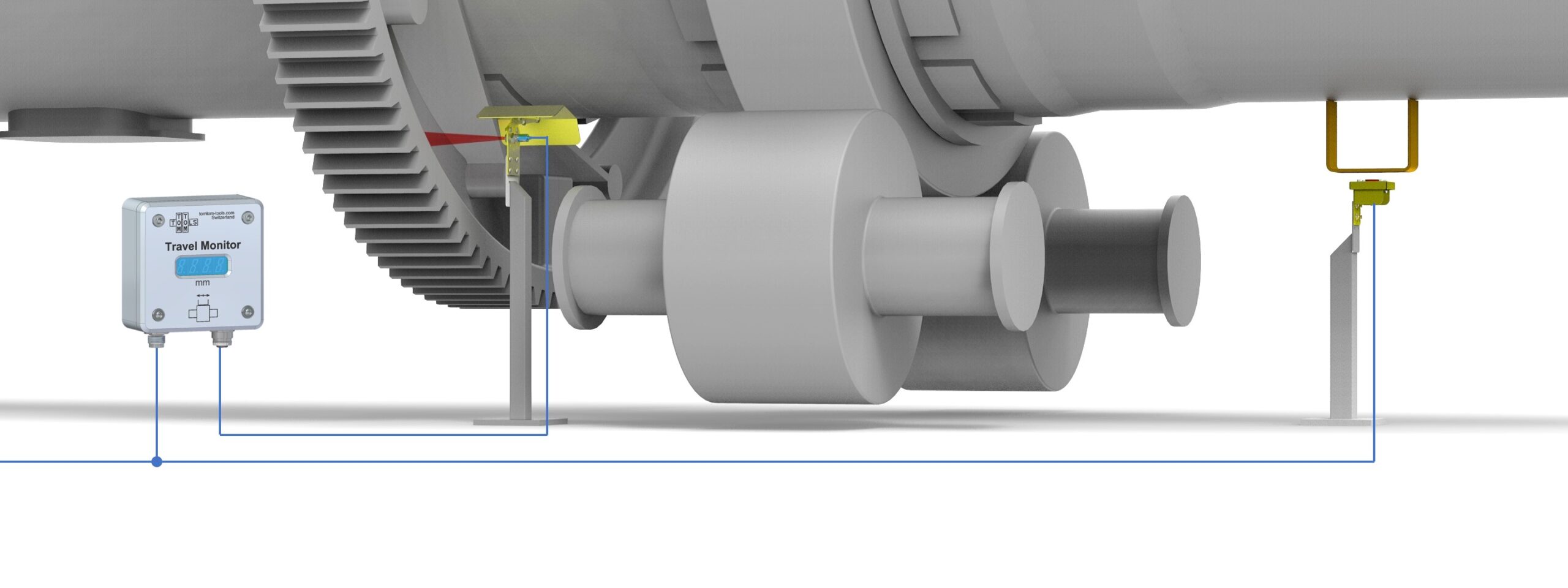

The Travel Monitor is part of the new MKM System 2 and is used to measure the axial travel or position of the kiln.

The kiln is moved up and down typically with one or more hydraulic thrust roller to achieve a uniform wear pattern on the support rollers and gear drive.

Measuring Principle

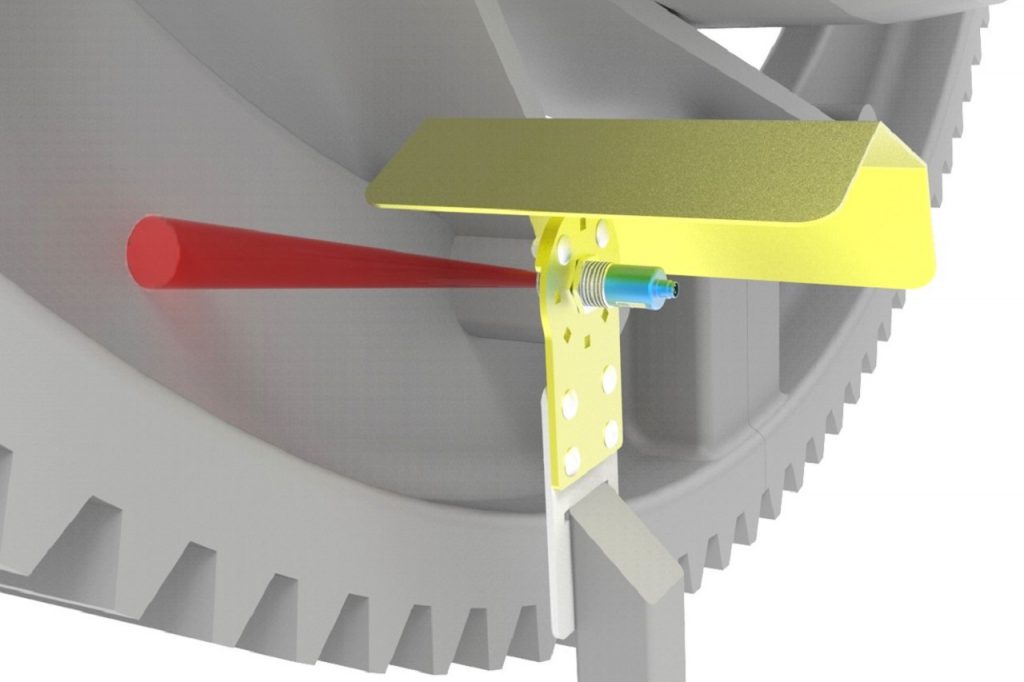

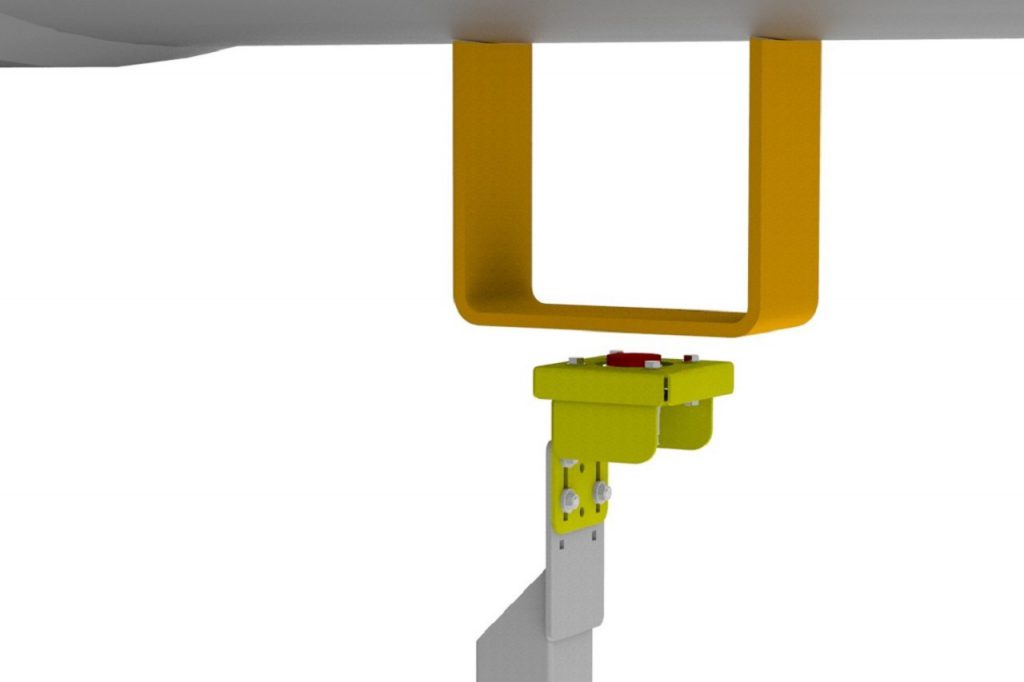

The Travel Monitor is measuring the kiln position with the help of an ultrasonic distance sensor. With the help of an additional reference sensor, which is indicating the rotation of the kiln, the controller is able to calculate the minimum distance of the ultrasonic sensor at each kiln turn. By comparing the change of these minimum values, the axial kiln movement is known.

The main advantage of this system compared to others is that the measurement is not affected by deviations in the straightness of the measured surface. That allows to use any side surface on the kiln. A good place to locate the Travel Sensor is next to the girth gear.

The values are shown on the display and are provided via a 4…20mA analog signal.