Kiln Shell Laser

Introduction

The Kiln Shell Laser is a contact-free measurement tool to determine deformations of kiln or dryer shells and other slowly rotating, large cylinders during operation. The system can be used to measure individual cross-sections as a spot-check as well as the whole kiln using several measurements. The steel shell of rotary kilns is exposed to high temperature. In case of excessive heat the shell might deform. In areas with deformations the refractory installation becomes typically difficult, which has a negative impact on its lifetime.

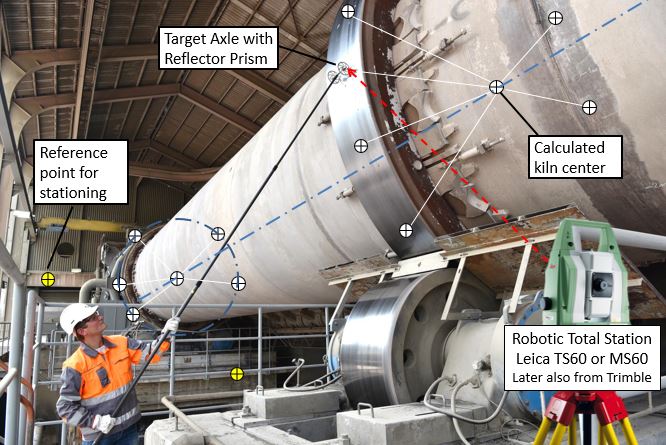

Measuring Principle

To measure the shape (roundness and eccentricity) of the shell, the Kiln Shell Laser is placed along the rotating kiln and measures continuously the distance to the shell surface. Deformations result in changes of the distance and will be recorded by the laptop PC, which is connected via Bluetooth with the laser. From each measured position a graph with the cross-section of the kiln is generated. Several measurements along the kiln can be combined in the software to a full 3d graph.

The 3d graph shows the severity of the deformations in different colors. It is a great help to identify the areas where special attention to the refractory is required. In case of reduced refractory life time, due to shell deformation, the software helps to decide, which shell sections need to be replaced.