Creep Monitor

Introduction

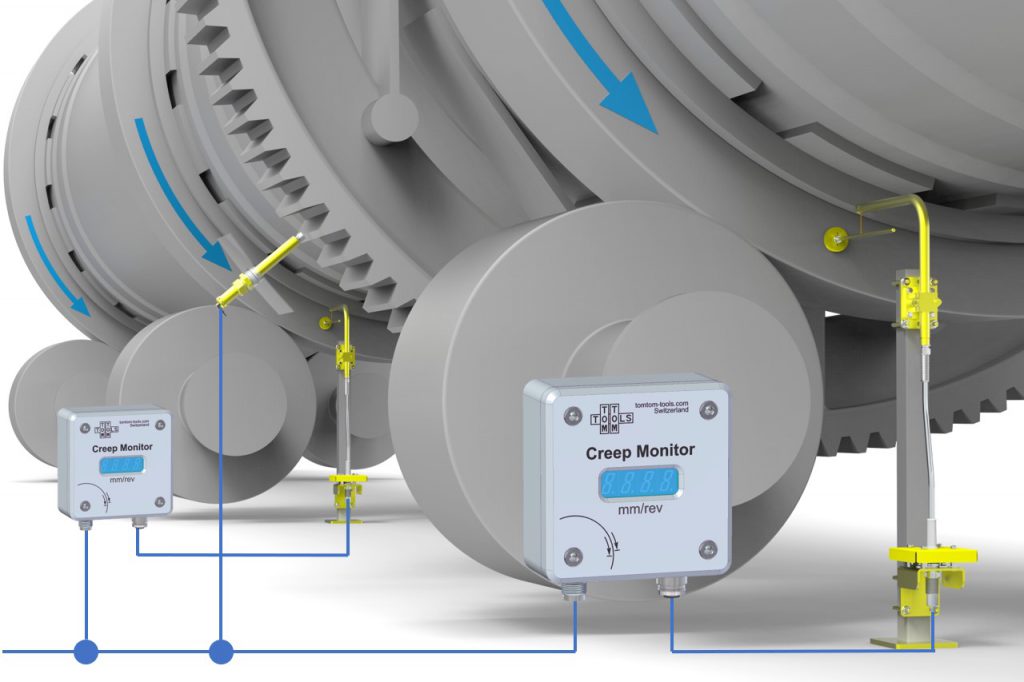

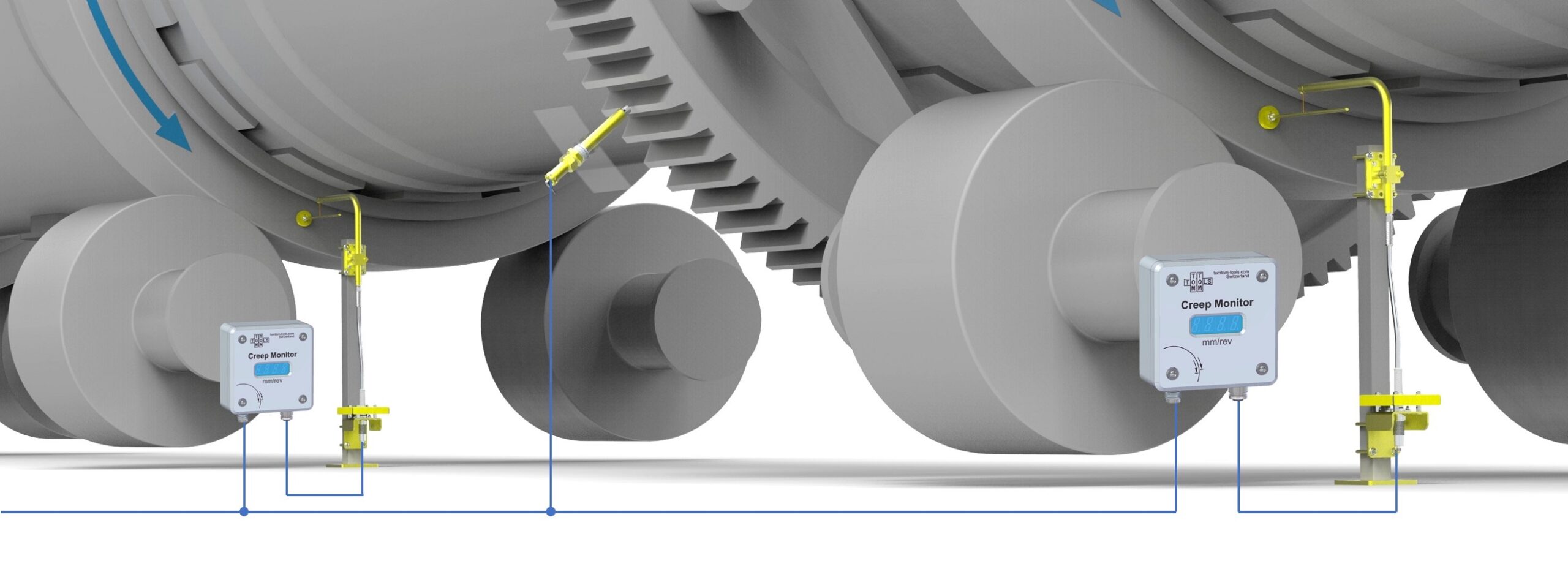

The Creep Monitor is part of the new MKM System 2 and is used to measure the creep, migration or also called relative movement of tires or riding rings on rotary kilns or dryers.

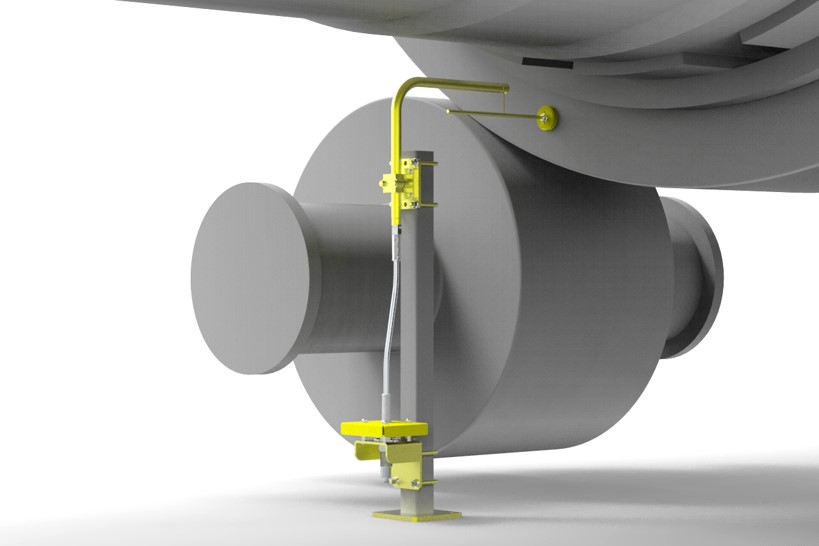

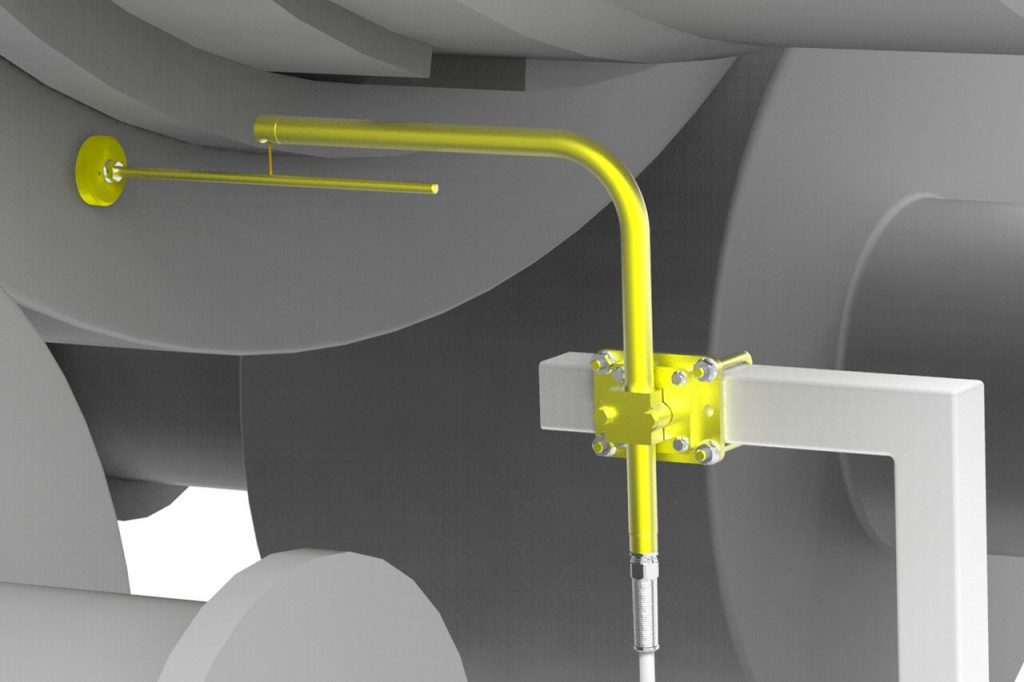

It is designed for permanent installation to provide reliable information about the remaining clearance between kiln shell and tires.

The great advantage compared to other systems is that the TomTom-Tools Creep Monitor provides reliable values already during the heating up phase when the kiln is not yet continuously turned. During heating the clearance on the tire goes often critically low because the kiln shell heats up and expands much faster than the tire.

Measuring Principle

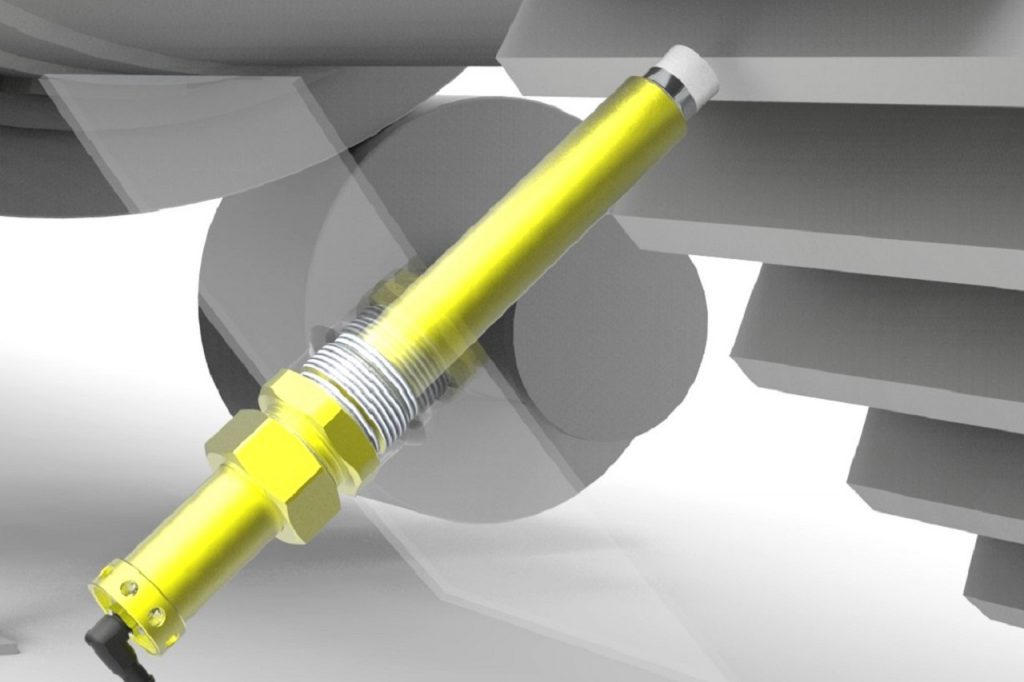

The controller is comparing the required time for a turn of the kiln shell with the time of the tire. By knowing the shell diameter, the controller calculates the relative movement and displays the value in millimeter per revolution [mm/rev]. Therefore, two sensors are required. One provides the rotation signal from the kiln shell, the other from the tire.

By using the teeth of the girth gear as rotation signal, the full benefit of the Creep Monitor’s algorithm can be utilized. With that, the controller does not require continuous rotation to calculate the creep and provides already during the heat up phase reliable results.

The values are shown on the display and are provided via a 4…20mA analog signal.