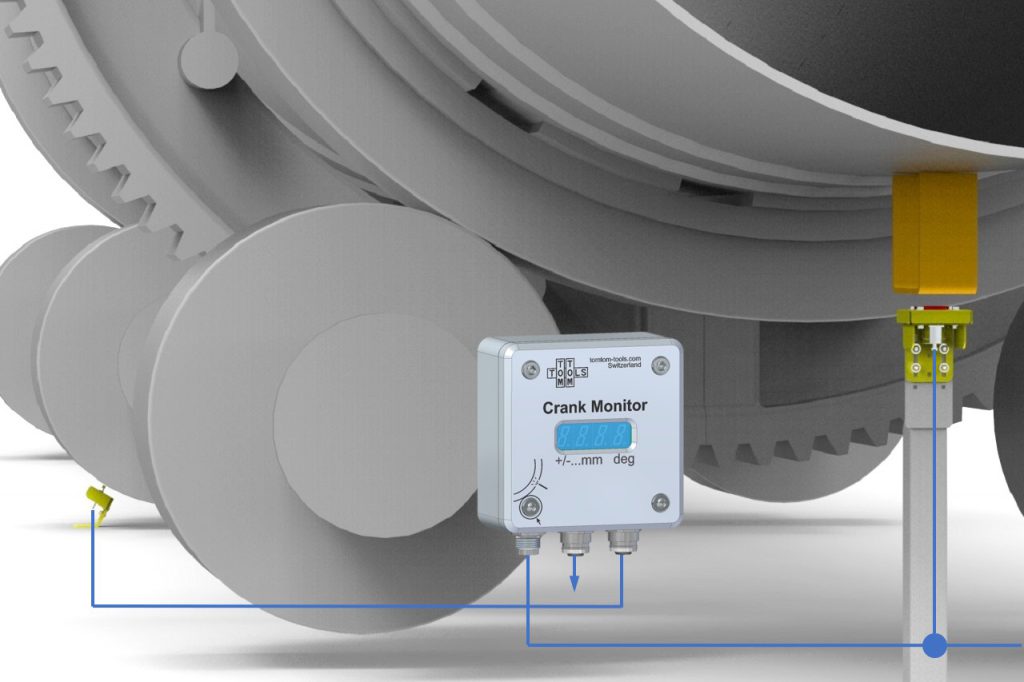

Crank Monitor

Introduction

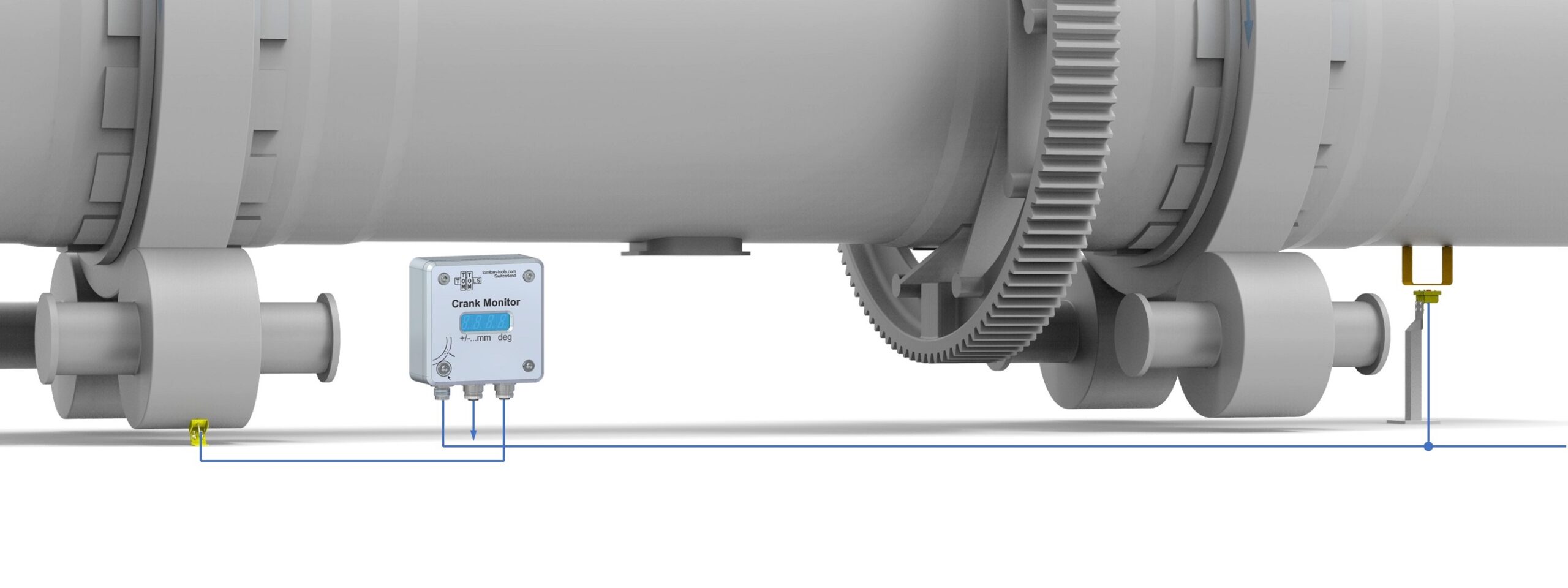

The Crank Monitor is part of the new MKM System 2 and is used to measure and warn about cranks in the kiln. It even can be used as controller for the patented Crank Elimination System which can neutralize cranks by selective shell cooling. More information about counteracting cranks is available separately.

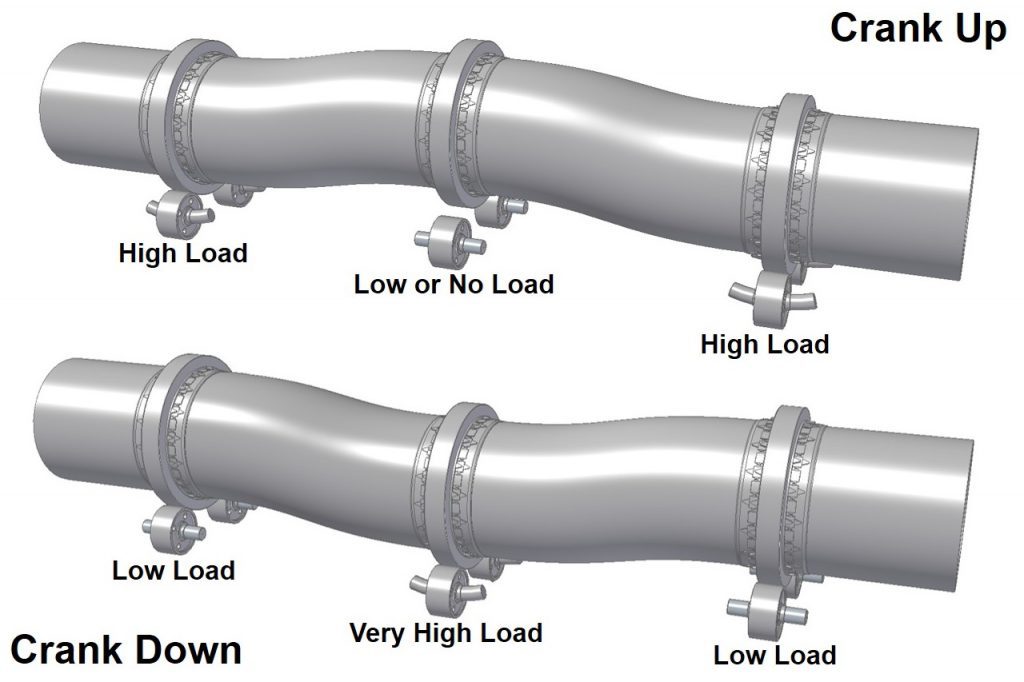

A crank is a deviation in the straightness of the kiln shell, which causes cyclic changes of the support load in the piers. Cranks can cause extreme overload and major damage. They are the main cause for cracks in tires, breakages of roller shafts and sinking foundation.

The Crank Monitor is designed to be installed permanently on kilns with more than 2 piers.

Measuring Principle

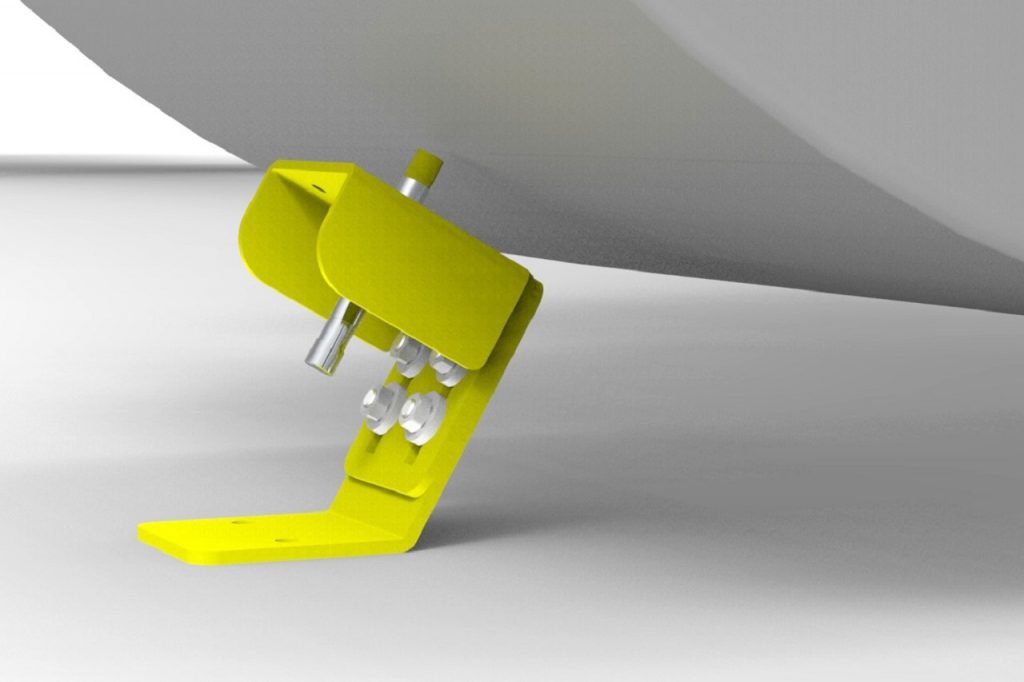

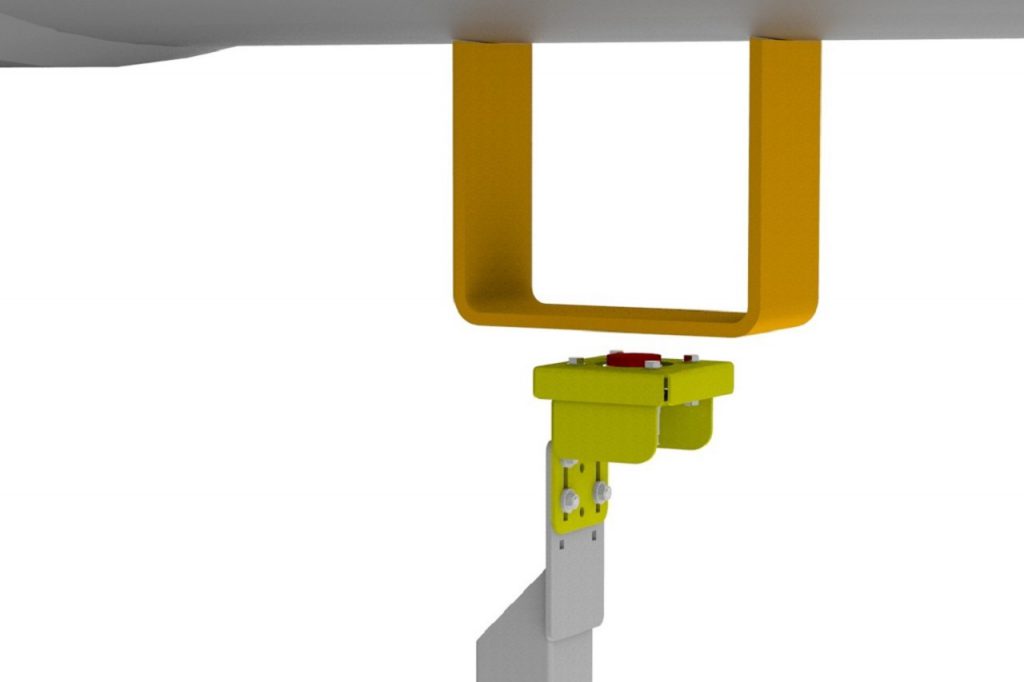

The Crank Monitor measures the variation in the deflection of one roller shaft at the middle pier(s) with an inductive distance sensor. By combining the roller shaft bending signal with the reference signal, indicating the kiln rotation, the controller is calculating the amplitude and the phase angle of the crank. The amplitude indicates the severity of the crank. The phase angle shows where the peak of the crank is located in circumferential direction.

The special sine fit algorithm in the controller provides very stable and reliable results already after one continuous turn with the auxiliary drive and even on rollers with damaged surface.

The values are shown on the display and are provided via two 4…20mA analog signal.