TI-MVX Ultrasonic Thickness Gauge

The CHECK-LINE model TI-MVX offers a series of advanced features including A-Scan, B-Scan as well as a complete alphanumeric data logging system with a storage capacity of thousands of data values and A-scan captures.

The TI-MVX features the highest resolution graphic LCD on the market and is specially engineered for optimal ease of use. It is supplied as a complete kit with all accessories in carrying case with software, transfer cable, and NIST-Traceable Calibration Certificate.

Features

- Includes NIST-Traceable Calibration Certificate

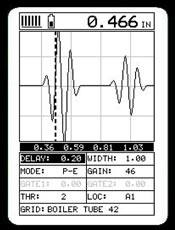

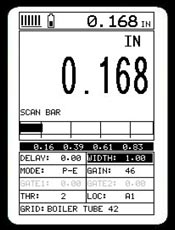

- The MVX is equipped with multiple viewing options to provide users with a complete set of inspection tools: (RF waveform, +/- Rectified waveform, Time based B-Scan, and Large Digits).

- The A-Scan rectified mode is commonly used for detecting flaws/pits in pulse-echo mode and measuring through paint and coatings in echo-echo mode.

- The time-based B-Scan feature of the MVX displays a cross section of the test material. It is commonly used to display the profile of the bottom surface of the test material.

- Built in hardware AGC gain control for through paint measurements in multi mode operation.

- The MVX has the ability to store 64 custom user defined setups. All factory setups can be selected, edited and saved to any setup location.

- Use the visual alarm to set hi and lo limits for applications requiring specific tolerances. If the actual thickness value is above or below the limits, a red light is illuminated.

- Use the find feature to locate the detection point, while automatically adjusting the display to bring the signal into view.

- MVX also comes complete with our Windows® PC software for transferring data to and from a PC.

- Includes Flaw Inspection – Prove Up Mode, (special probe required)

- The high speed scan feature speeds up the inspection process by making 32 measurements per second. Remove transducer from the tesst material, and display the minimum measurement scanned.

- IP 65 Rated

- CE Certified

- Warranty: Gauge: 2 Years Probes: 90 Days

- Made in USA

Display mode

| A-Scan Scan Mode | B-Scan Mode | Large Digits |

|  |  |

| The A-Scan rectified mode is the preferred display view for flaw and pit detection applications and measuring through paint and coatings in the echo-echo mode. | The B-Scan view displays a time-based cross section of the test material. It is commonly used to display the profile of the blind or underside of a pipe or tank. | The Large Digits view provides a basic digital thickness gauge look and feel. The large display makes it easy for the operator to monitor the thickness readings. |

Specifications

| Range in Steel: | Pulse-Echo Mode: Pit and Flaw detection measures from 0.63 to 254 millimeters (0.025 – 9.999inches) Echo-Echo Mode: Thru Paint & coatings measures from 2.54 to 102 mm (0.1 – 4.0 inches). |

| Resolution: | .001 inches (0.01mm) |

| Velocity Range: | .0492 to .3936 in./ms 1250 to 9999 meters/sec |

| Units: | English & Metric |

| Measurement Modes: | – Pulse-Echo (flaws, pits) – Echo-Echo (thru-paint) |

| Transducer Types: | Dual Element (1 to 10 MHz). |

| Memory: | 16 megabit non-volatile ram |

| Memory capacity: | 12,000 pages with 1 reading and waveform per page |

| Power Source: | Three 1.5V alkaline or 1.2V NiCad AA cells |

| Battery Life: | Typically operates for 150 hours on alkaline and 100 hours on NiCad |

| Auto Power off: | if idle 5 min |

| Display: | 1/8 in. VGA grayscale display 62 x 45.7mm |

| Keyboard: | Membrane switch with twelve tactile keys |

| Case: | Extruded aluminum body with nickel-plated aluminum end caps (gasket sealed). |

| Operating Temperature: | -14° to 140°F (-10° to 60°C) |

| Weigth, net: | 383 grams |

| Dimensions: | 63.5 W x 165 H x 31.5 D mm |

| Warranty: | 2 year limited |

| Certification: | CE Approved, Factory calibration traceable to national standards |

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

At the Maryneal, Buzzi Unicem USA faced an ongoing battle with frequent conveyor roller failures.

Each failure threatened the plant’s safety and disrupted

- By Admin Faadtech

- Comments are off for this post.

The Meaning of Reliability Centered Maintenance

Reliability Centered Maintenance (RCM) is a process for planning and executing maintenance activities with a focus on enhancing the reliability of equipment and machinery.

It involves analyzing potential failures and their

FOREVER AND A DAY TECHNOLOGY

Product

Uncategorized

฿38,500.00 Original price was: ฿38,500.00.฿35,500.00Current price is: ฿35,500.00.

Quick View

MicroScanner™ PoE Cable

Uncategorized

฿9,850.00 Original price was: ฿9,850.00.฿8,850.00Current price is: ฿8,850.00.

Quick View

IntelliTone Pro 200 Probe

Uncategorized

฿38,500.00 Original price was: ฿38,500.00.฿35,500.00Current price is: ฿35,500.00.

Quick View

MicroScanner™ PoE Cable

Uncategorized

฿9,850.00 Original price was: ฿9,850.00.฿8,850.00Current price is: ฿8,850.00.

Quick View

![เมาท์ติ้งแม่เหล็กแบบเรียบ เกลียว 1/4-28[MH103-1B ] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/MH103-1B-CTC.3-300x300.jpg.webp)

![เมาท์ติ้งแม่เหล็กแบบเรียบ เกลียว 1/4-28[MH103-1B ] CTC เมาท์ติ้งแม่เหล็กแบบเรียบ เกลียว 1/4-28[MH103-1B ] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/MH103-1B-CTC-600x600.jpg.webp)