GEOMETRY ─ THE EASY WAY

NXA Geometry

Software

Standard straightness for measurement of e.g. machine beds, guideways, or support structures.

Straightness for full and half bore applications when measuring e.g. bearing journals in gearboxes, diesel engines, compressors, and turbines with split casings.

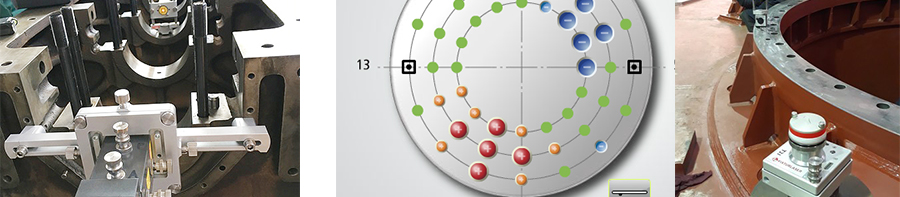

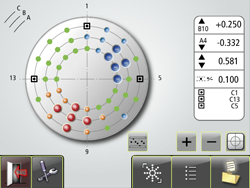

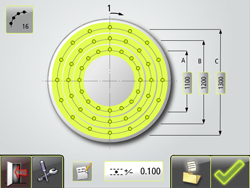

Flatness measurements, both rectangular and circular, of foundations and machine beds when installing machines.

Receiver

The NXA Geometry comes in two versions, the NXA Geometry Basic and NXA Geometry Full respectively.

The content is the same with one exception for the NXA Geometry Full version, which also includes an extra receiver, the RS sensor unit, as described below

GuideU – Adaptive graphical user interface

The laser-based geometry systems by Acoem are characterized by their user-friendliness, thanks to an industry-leading adaptive graphical user interface.

We pride ourselves in developing our products to be as easy to handle as possible, regardless of whether you use your measurement equipment on a regular basis or just a few times a year. We also value your time, being user-friendly also means being fast!

With our systems’ graphical user interface, GuideU, you do not have to waste time on refreshing your memory or on second-guessing yourself during the actual work; our user interface guides you throughout the entire measurement and adjustment or alignment process. Below you will find an example of the graphics for a circular flatness measurement!

R2 SENSOR UNIT

An optional extra R2 sensor unit can be used as a reference detector during your measurement.

2-axis 20 mm PSD detector

Slim design

Rechargeable Li-Ion batteries

Target integrated into fixture

Integrated direction coordinates

Inclinometer with high accuracy

Integrated Bluetooth for wireless communication between the display unit and smart sensor

Instant battery check-in both on and off mode

TRANSMITTERS

For straightness measurements, choose between the T110 or T111:

Laser transmitter T110

For straightness applications

Rigid design for measurement stability

Laser range up to 50 m

Micrometer screw for adjustment of the laser transmitter in both horizontal and vertical level

Powered by battery

Laser transmitter T111

- สำหรับการวัดและตรวจสอบความตรง

- การออกแบบที่เข้มงวดเพื่อความเสถียรในการวัด

- ช่วงเลเซอร์สูงถึง 50 m

- สกรูไมโครมิเตอร์สำหรับปรับระดับเครื่องส่งเลเซอร์ทั้งแนวนอน และแนวตั้ง

- ขับเคลื่อนโดยอะแดปเตอร์ AC

For straightness and flatness measurements, choose between the T21 or the T220:

Laser transmitter T21

For applications such as straightness, flatness, and squareness

Compact design for measurement stability

Measuring distance up to 20 m

Manual adjustment of the laser turret

Battery-powered transmitter

Laser transmitter T220

For applications such as straightness, flatness, and squareness

Robust design for measurement stability a high measurement accuracy

Measuring distance up to 50 m

Micrometer screw for rotational adjustment of the turret

Built-in spirit levels and micrometer screws for adjustment of the laser transmitter

Battery-powered laser transmitter

Accessories

AT-010 RUNOUT PROBE

The AT-010 Runout Probe is a battery-powered displacement probe connecting wirelessly via Bluetooth to the NXA display unit.

It can be used for:

checking bearing clearances

checking axial and radial runout on flanges

measurement during the positioning of machine components.

Level

The Level is a battery-powered two-axis measuring sensor that connects wirelessly via Bluetooth to the NXA display unit.

It can be used for:

as a digital level

for leveling machines or machine parts during installation

for measuring twist on linear guideways

for measuring parallelism between machine foundations.

Angular Prism

The angular prism is used for the measurement of perpendicularity and parallelism together with any NXA Geometry transmitter, R2 sensor, and a display unit. It is useful when measuring eg:

parallelity between two linear guides

perpendicularity of flanges

squareness between linear guides/machine components

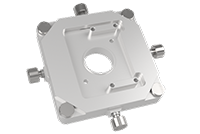

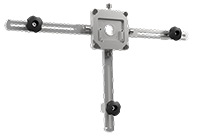

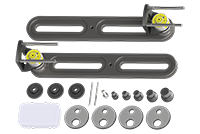

XY Table

XY table with long arms

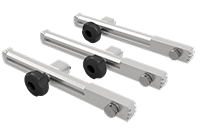

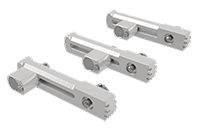

3 long arms with magnets for XY table, ø300 – 600 mm

Set of short arms for XY table, ø180 – 300 mm

Sliding table

Protective foil for the display screen

Magnetic base

Tripod

Angular bracket with a tripod adapter

Chain 8 mm 60 links

Can be used as an extension chain. Delivered with hooks.

Offset fixtures and software

Complete set of fixtures and software for alignment of offset mounted machines/cardan coupled machines.

OL2R fixtures with software

For the measurement of dynamic movements from offline to running conditions

AT-010 Run-out probe

A smart displacement probe for safe and reliable measurement of axial and radial runout.

LEVEL

A measuring sensor used for leveling machines or machine parts during installation.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.