Predictive maintenance powered by artificial intelligence (AI)

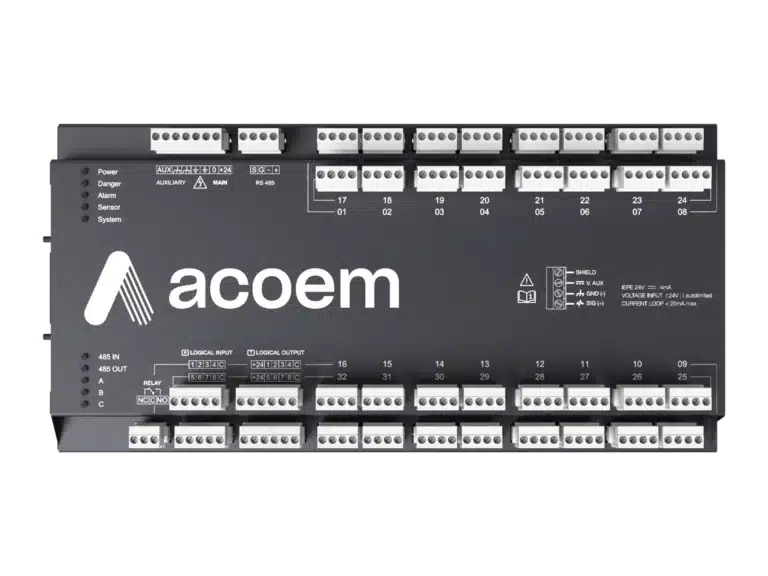

Acoem brings to you MV-x Black edition ,the next generation of AI-enabled vibrational analysis, with real-time edge computing, provides a pathbreaking predictive tool to pinpoint the source, direction, and intensity of the vibration. It represents a fundamental shift from reactive maintenance to predictive maintenance. More importantly, it provides vibration analysis and condition monitoring users, with a seamless industry 4.0 experience.

MV-x Features

Patented AI solution that provides immediate, easy-to-understand machine diagnostics.

Accurex AI for automatic diagnosis with intelligent data processing on the MV-x to save storage and bandwidth.

Smart Monitoring

Smart MonitoringCommunicate within your plant using Modbus or OPC/UA.

AI-powered vibrational data for accurate insights

Acoem’s MV-x is a multi-channel real-time wireless monitoring & diagnostics system that seamlessly integrates into the digital industry environment and delivers high-value data insights. With integrated Artificial Intelligence and the power of edge computing, it creates a secure, localised and early fault detection ecosystem, when vibrations deviate from the norm. Through instant and precise data points, it indicates the impending problem and offers remote diagnostic capabilities, empowering you to act before the event, averting downtime and its cascading consequences.

This makes the Acoem MV-x a powerful predictive maintenance program and an invaluable tool for condition monitoring, which provides peace of mind to operators across diverse industrial settings. It is already a solution of choice for industrial applications around the world — including wind turbines, petrochemical plants, maritime transportation, logistics, mining, and automotive manufacturing.

⏳Real time monitoring

Condition based maintenance advocates continuous monitoring of machinery at periodic intervals, using various vibration indicators. Acoem goes even further, as MV-x and MV-120 offer the capacity to monitor indicators in real time, ensuring:

- that no monitoring event will be missed (no gaps in data acquisition)

- responsiveness at all times: the slightest anomaly is detected in real time

- the ability to detect transient or spurious events

- Pre-trigger functions enabling the raw signal from just prior to the event.

Monitoring for slow rotating shafts

The predictive maintenance of low speed rotating machines is more complex to implement. The machine condition is indeed more difficult to assess, as it requires high resolution data and advanced vibration analysis tools. Coupled to Acoem NEST platform, the MV-x and MV-120 systems offer the perfect solution:

- The synchronous record of several rotations of low speed shafts (<10RPM) can be performed on up 32 channels and such enhance bearing fault detection with the analysis of both low and high frequency content.

- The shocks resulting from low speed components are hidden in rich vibration signals and are very difficult to detect. Thanks to Acoem Shock Finder™, a smart algorithm developed on real applications, their detection is automatic and provides an early indication of fault on such low speed asset.

- All analysis tools required are available: statistical analysis, band kurtosis, smart filters… All post processing indicators can be trended and help predict the evolution of the asset condition

Real time monitoring

Condition based maintenance advocates continuous monitoring of machinery at periodic intervals, using various vibration indicators. Acoem goes even further, as MVX and MV-120 offer the capacity to monitor indicators in real time, ensuring:

- That no monitoring event will be missed (no gaps in data acquisition)

- Responsiveness at all times: the slightest anomaly is detected in real time

- The ability to detect transient or spurious events

- Pre-trigger functions enabling the raw signal from just prior to the event.

Monitoring of complex machines

On the edge of industry 4.0, recording data is not a problem any longer. But for machines operating according to variable process conditions, the difficulty is now to provide a solution able to capture the right data at the right time, to enable reliable analysis and predict failures. MVX and MV-120 performances enable the most complex machinery found in today’s industrial processes to be monitored:

- Up to 10 operating conditions can defined using one or more process parameters

- Data Acquisition strategy, Indicators and alarm thresholds are automatically adapted according to each operating condition

- Stability parameters are set to make sure each measurement is done in good condition

Troubleshooting

MVX system can be packaged in a transportable case with BNC plate for 8, 16, 24 or 32 channels to answer to a need of temporary monitoring:

- IP54 rugged design, with integrated fan system and UPS

- place to enclose a 15’’ laptop PC

- dimensions: 560 x 465 x 265 mm (22.0 x 18.3 x 10.4 inches)

- weight: 16 kg (30 lbs)

Externally powered, the monitoring case can remain closed even with a computer inside and right next to the equipment during a day, a week, a month… Ideal to run a full health assessment of the most complex machines, it offers the best measurement and signal processing capabilities for troubleshooting purposes.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.