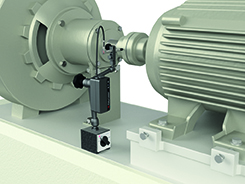

Pre-alignment AT-010

🔒 Discover the Pinnacle of Precision: Acoem EXO

Safeguard Your Maintenance Team & Production

Features

Eliminating soft foot is crucial to achieve precision alignment

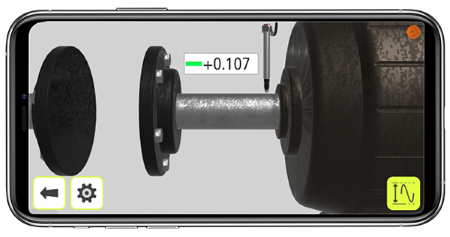

Your digital dial indicator

AT-010 Run-Out Probe

The maintenance professional’s little miracle worker!

The AT-010 is a pre-alignment tool with a multitude of applications with which you can determine if your machine is really suffering from a misalignment, or a pre-alignment condition, e g softfoot.

The importance of pre-alignment

Industry-First Combination – Displacement & Shaft Alignment

- Axial and radial runout checks on flanges

- Checking movements on machine feet (soft foot)

- Checking bearing clearances

- Checking movements due to pipe strain

- Thermal growth measurements on machine casings

- Eccentric or skewed mounting of coupling hubs

- Checking for bent shafts

AT-010 Run-Out Probe Applications

True Softcheck – An Industry First Application

A softfoot condition needs to be corrected before any shaft alignment takes place. Otherwise, it is more or less impossible to properly align a machine with an existing soft foot condition.

The AT-010 Run-Out Probe measures directly on the machine foot the play that occurs as you release the bolt. The user will obtain true softfoot values in contrast to other methods that measure the shaft movement/s as an indication of softfoot.

Measure the actual movement on each foot

Clear on-screen guidance to achieve perfect results

Results are saved for the report and later review

The adjustable probe tip can be adjusted for use on machines with space restrictions around the foot during SoftCheck

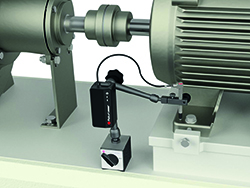

Bearing Clearance

Correct bearing clearance is important for achieving good alignment results.

Detects bearing wearChecks for excessive bearing clearance radially and axially

Checks for excessive bearing

Results saved to report

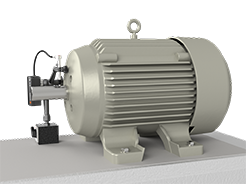

Run-Out

Bent shafts, skewed or eccentric mounting of coupling hubs can cause harmful vibrations.

Check runout on shafts and couplings with just one rotation

Onscreen setup and measuring guidance

Results saved to report

What is Pre Alignment

📌 Meaning of Pre-Alignment

Pre-alignment is the process of performing initial checks and corrections on various parts of a machine before final alignment. It typically includes:

- Checking that the machine base is secure and not loose

- Ensuring the shaft can rotate freely without stiffness or binding

- Inspecting the machine feet to make sure there is no soft foot condition

- Verifying the alignment of belts or other components that might pull or twist the machine

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.