Laser shaft alignment ECO / ECO PRO

Laser shaft alignment NXA Ultimate

The Name Says it All!

With the NXA Ultimate you have covered any kind of angle that needs to be covered of your machinery. It includes shaft alignment applications as well as geometric applications, hence, as the name says, it is an ultimate measurement tool.

Features

Flatness

Flatness Straightness

StraightnessIntroducing the NXA

Horizontal and Vertical Machines

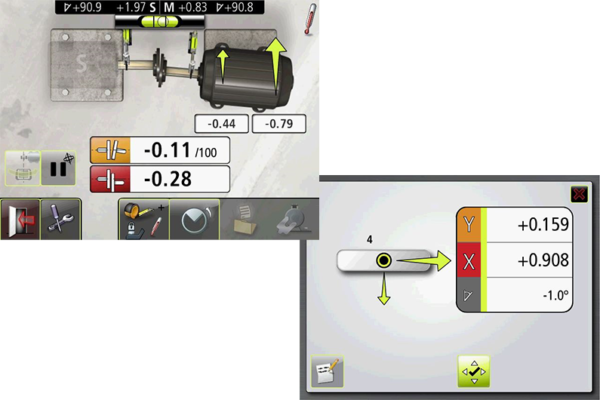

The NXA Ultimate is perfect for measuring horizontal alignment conditions but its real power is in helping correct misalignment. The dual sensors allow the NXA to maintain the true position of the shafts, even as unintended movements are experienced during the alignment process. The benefit of this “true positon sensing” is that it allows the user to complete the alignment using the VertiZontal™ compound move, adjusting in both the vertical and horizontal planes without remeasuring between moves. A Verti-Zontal™ alignment is a great time saver since alignments can be completed in just one or two tries. The NXA Ultimate also comes with a number of utility programs to make the alignment process easier. These include Softcheck™ to control for soft foot conditions, FeetLock™ to deal with base and bolt bound situations, HotCheck™ to calculate the difference between measurements taken in a cold state versus a hot condition, and Target Values, which automatically adjusts the readings to compensate for pre-determined alignment targets based on thermal growth or dynamic movement data.

The same power and ease of use found of the horizontal alignment program can be found in the vertical alignment program. The vertical alignment program is used when aligning flanged-mounted machines.

Machine Train

The NXA’s machine train routine simplifies the complexity of aligning multiple units with connecting shafts. The software includes a “minimal moves” function which identifies the best reference machine to minimize the number of moves required to complete the alignment.

Spacer Shaft

With spacer shafts there are two power planes of transmission that need to be aligned to the correct tolerances. The NXA spacer shaft program simplifies the process showing both ends of the spacer shaft coupling with an angle/angle display. The alignment is completed using the Verti-Zontal™ move.

Shaft alignment

The NXA Ultimate comes with technology enabling functions and capabilities, which in many cases are industry firsts, for example:

- CCD detectors with ultra high definition resolution.

- New sensor units with Bluetooth incorporated are the industry’s most compact, yet, they feature a 30 mm detector surface and line lasers.

- The OmniView™ feature keeps track of the position of both the user and the machine to show the screen display from the user’s perspective, thanks to the built-in gyroscope (6-axis MEMS Inertial Motion Sensor) in the display unit.

- Ability to keep track of the position of the sensors in both the vertical and horizontal orientation, and any inclination in-between, when performing a shaft alignment, thanks to the built-in gyroscope in the sensor units. Hence, you are then able to perform a shaft alignment on vertically mounted machines where it is not possible to do a 180° shaft rotation.

- Excellent power management – 10 hours on one charge.

Live adjustment

You always know your machine’s position with the NXA Ultimate! It delivers live values during measurement and simultaneous live adjustment during the adjustment process, with measurement results shown in micron resolution. In the straightness program, adjustments are made live in dual-axis.

Rugged design and IP65 certified

All our products are IP 65 which means that the NXA Ultimate is rated as dust tight and is protected against water projected from a nozzle. You can trust the NXA Ultimate in harsh industrial environments!

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.