Laser shaft alignment EXO

🔒 Discover the Pinnacle of Precision: Acoem EXO

Safeguard Your Maintenance Team & Production

Features

🎯 Unmatched Precision – Acoem EXO

We combine cutting-edge technologies like GuideU™ and Alignment Intelligence to deliver unique innovations

🛡️Safe & Powerful – FIXTURLASER EXO

Designed specifically for hazardous environments, this device delivers professional-grade performance with total safety in mind.

📡 True Live™ – Real-Time Shaft Alignment

This feature provides continuous live alignment readings: Even if the laser beam is interrupted or the machine is moved

🚀 Fast, Easy, and Accurate Shaft Alignment

Acoem EXO is the smart, safe, and modern solution for all your shaft alignment needs!

Streamlined Shaft Alignment for Hazardous Environments

Streamlined Shaft Alignment for Hazardous Environments

🎯Unparalleled Precision – True Live™

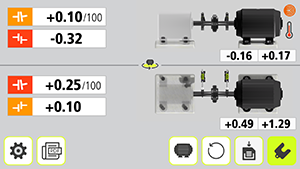

With the Acoem EXO, precision is real-time. Engage the transformative True Live feature, offering dynamic live measurement values that instantaneously reveal your machine’s precise position. Encounter interruptions in the laser beam or shift the machine beyond detector range? No worries. Our intelligent sensors seamlessly recalibrate, continuously furnishing live updates on your machine’s alignment.

Unlock Seamless Accuracy – Your Pathway to Effortless Alignment

Cutting-Edge EX Certified Smart Sensors

- Seamless Wireless Communication: Experience effortless connectivity between the display unit and smart sensors through integrated Bluetooth technology.

- Efficient Alignment Setup: Benefit from a quick setup with a 30 mm digital sensor detector and line laser that eliminates rough alignment, ensuring precision from the start.

- Enhanced Measurement Accuracy: Detect backlash and obtain angular values during horizontal alignment using built-in dual inclinometers, optimizing measurement results.

- Sleek and Compact Design: Utilize the market’s thinnest smart sensors, providing a space-saving and unobtrusive solution without compromising performance.

- Time-Saving Premounted Fixtures: Enjoy swift setup with pre-mounted fixtures, streamlining the process and maximizing productivity.

- Instant Battery Assessment: Check battery status instantly in both on and off modes, ensuring uninterrupted operations and minimizing downtime.

- Certified Safety: Confidently operate with II 3G Ex ic op isIIC T4 Gc certification, ensuring compliance and safety in potentially hazardous environments.

EX certified tablet with an app and icon-based

- EX Certified Tablet and App: Explore precision with our EX certified tablet featuring a user-friendly app, perfectly suited for hazardous environments.

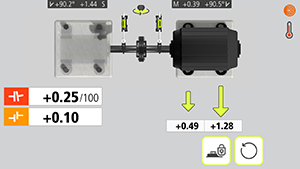

- Intuitive Icon-Based Interface: Seamlessly navigate with an icon-based, color-coded interface that transcends language barriers, ensuring universal usability.

- Real-time Alignment Updates: Experience the power of true live values throughout adjustments, providing immediate insights into your alignment progress.

- Visual Guidance with Animated Arrows: Enhance alignment precision using animated arrows, guiding your adjustments with orientation cues and vivid misalignment indications.

- Effortless Wireless Communication: Stay connected effortlessly with integrated Bluetooth, enabling seamless communication between the tablet and smart sensors.

- Ruggedized Excellence: Achieve safety and durability with ATEX/IECEx Zone 2 certification, paired with an IP68 ruggedized tablet, built to withstand challenging environments.

GuideU

Enhance Your Alignment Experience

Experience seamless job measurement, alignment, and documentation with GuideU™, our patented icon- and app-based, color-coded user interface. Simplifying the alignment process, GuideU™ is tailored to the FIXTURLASER EXO system, ensuring minimal operator errors. It expertly guides users through logical steps, delivering accurate measurement and correction values.

Benefit from clear guidance, especially for novice users, ensuring effortless navigation with the FIXTURLASER EXO system. The 3D graphical interface not only enhances user experience but also facilitates error interpretation. Our intuitive, icon-driven alignment systems generate language-free measurement reports, accessible to all users, regardless of language proficiency.

Vertizontal Moves™

Optimized Precision with Vertizontal Moves™

Streamline Alignment with a Single Measurement

Vertizontal Moves™ revolutionizes precision adjustments by revealing precise corrective actions in two directions. Seamlessly add or remove shims from the machine’s feet to achieve optimal alignment, eliminating the need for re-measuring during vertical-to-horizontal transition.

This groundbreaking feature not only slashes downtime but also guarantees initial accuracy. Unleash substantial cost savings across maintenance, production, and your entire organization through enhanced efficiency.

Elevate Precision, Minimize Costs – Vertizontal Moves™ at Your Service

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.