Grease pumps air operated Rate 1:50

| Grease pressure: | 5,800 psi |

| Output: | 500 g/min |

| Pump tube: | Ø32 mm |

| Air pressure min-max: | 0,3-1 MPa/43-150 psi |

Description

For pail, 1/4-drum, or 1/1-drum.

Structure These 1:50 air operated grease pumps (Grease pumps air operated) are designed as a complete grease handling system for suctioning. All the grease in the grease tank comes out.

Technical info

- The pump consists of a drive section and a pump section. The drive section is an air motor driven by compressed air.

- The piston diameter of the air motor is 50 mm. The motor consists of an air cylinder with piston and one reciprocal valve. The valve directs the compressed air alternately to the top or bottom of the piston, thus producing a reciprocating motion of the air motor piston rod.

- The air motor is made of light alloy, stainless steel, brass, plastics and chromiumplated steel. It is thus highly resistant to rust caused by water in the compressed air.

- The pressure ratio of the pump states the ratio of the incoming air pressure to the media pressure. When the pressure ratio is 1:50, we achieve a pressure of 7,253 psi (500 bar) when the incomming air pressure is 145 psi (10 bar).

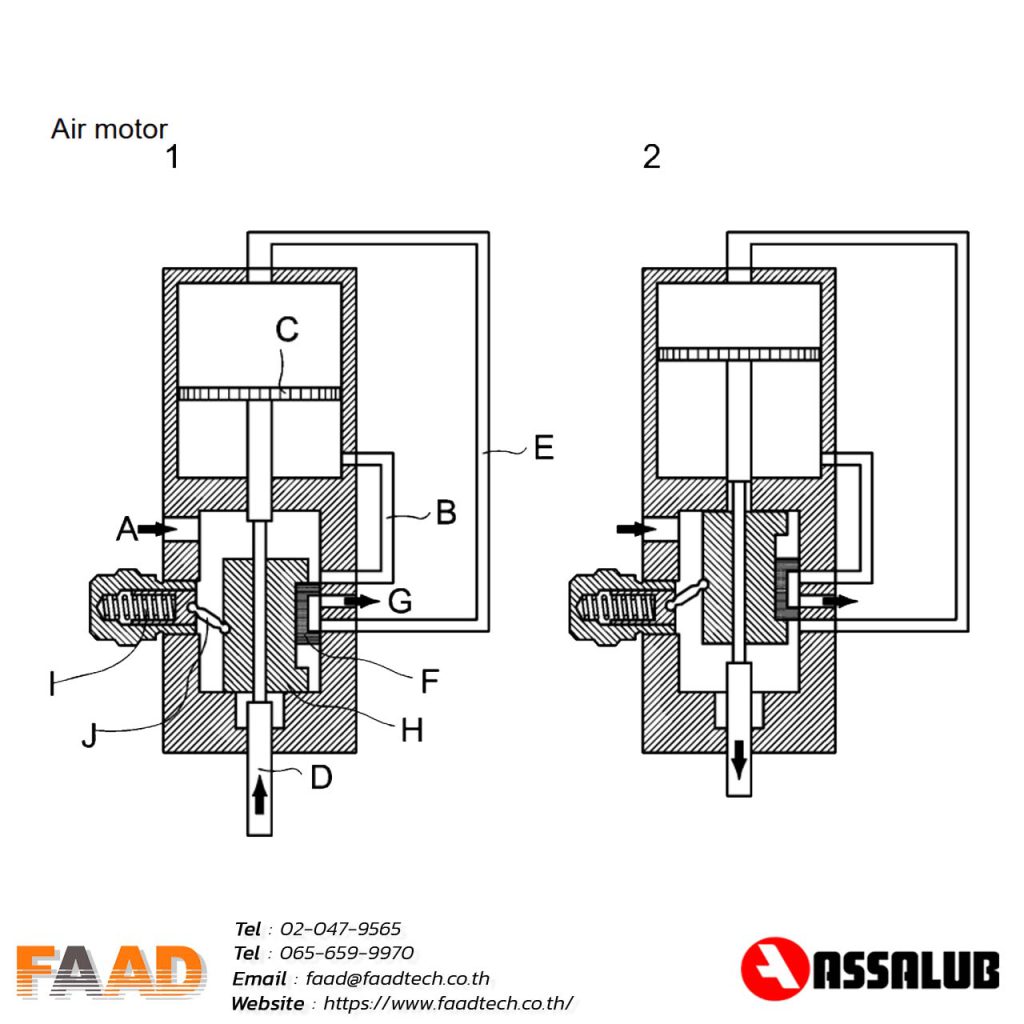

MODE OF OPERATION

When the piston moves upwards, see Figure 1:

Air enters at arrow A and passes through passage B to the underside of the piston C,driving the piston C and piston rod D upwards. The air above the piston is evacuated through passage E, past the valve slide F and out at arrow G.

The piston approaches top dead centre and the piston rod D makes contact with the slide driver H. When the slide driver H passes its mid position, the spring I and rocker J snap it over to its upper position, see Figure 2.

The incoming air is now led via passage E to the upper side of the piston C, driving it and the piston rod D downwards. The air under the piston C is evacuated through passage B, past the valve slide F and out at arrow G.

The piston approaches bottom dead centre and the piston rod D makes contact with the slide driver H. When the slide driver H passes it centre position, the spring I and rocker J snap it over to its lower position.

The air motor then repeats this cycle to produce a reciprocating motion, driven by compressed air.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![เมาท์ติ้งแม่เหล็กแบบเรียบ เกลียว1/4-28 [MH104-1B] CTC เมาท์ติ้งแม่เหล็กแบบเรียบ เกลียว1/4-28 [MH104-1B] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/MH104-1B-CTC-3-600x600.jpg.webp)