Portable Vibration and Online Vibration

What is vibration meter

Vibration is the oscillation or oscillation of objects around the equilibrium point, such as the swing of a pendulum. vibration of water pumps, etc. One industry can use the vibration meter together with other departments. To prevent accidents, whether it is a safety department to measure vibration to indicate the strength of the building structure, a maintenance department to prevent Breakdown, and other departments that have to work with various machines.

Which the vibrations that are beyond normal If neglect There is no inspection until damage. whether it happens to the machine or internal parts The end result is repair costs or breakdowns causing delays in production. The worst is You still have to buy a new machine. The vibration meter can help in inspection and maintenance work. In order to easily know the problem of the machine And there is no need to venture into dangerous areas.

หน่วยการวัดความสั่นสะเทือนหลักๆ มี 3 หน่วยคือ Displacement ,Velocity ,Acceleration

Displacement

often used to measure vibration of the machine cycle from the first moving point How many reference points do you reach? By measuring full wave (Peak to Peak)

It is commonly measured in millimeters (mm) or inches (inch).

used with machines with low rpm, no more than 1200 rpm or vibration with a frequency of no more than 20 Hz. |

Velocity

measure Machine rotational speed measured by RMS

measured in millimeters per second (mm/s).

Use with machines with a speed greater than 1,200 rpm or vibration with a frequency between 20 Hz-1000 Hz. |

Acceleration

measure The change in the ratio of the moving speed per unit time of an object moving at

It is commonly measured in millimeters/second squared (mm/s2).

| measure high-frequency vibrations from 10 kHz and above. |

Vibration Type

- Free Body Vibration Vibration at the direction of vibration is possible independently. along the direction of the force arising from the vibration with no solid parts coming Obstructs the direction of the vibrating parts such as chimes, drums.

- Meshing or Passing Vibration Constant vibration of machine parts compared to any reference point on the part conducting vibration analysis rotate or move through

- Frictional Vibration Vibration caused by rotating friction or movement of various parts of the machine

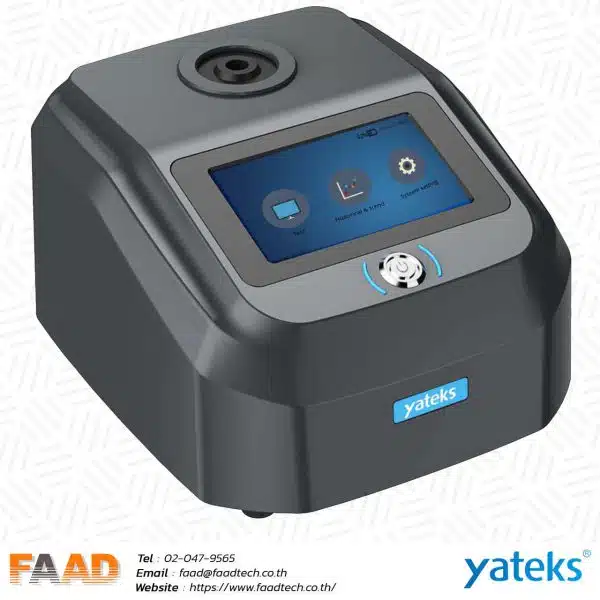

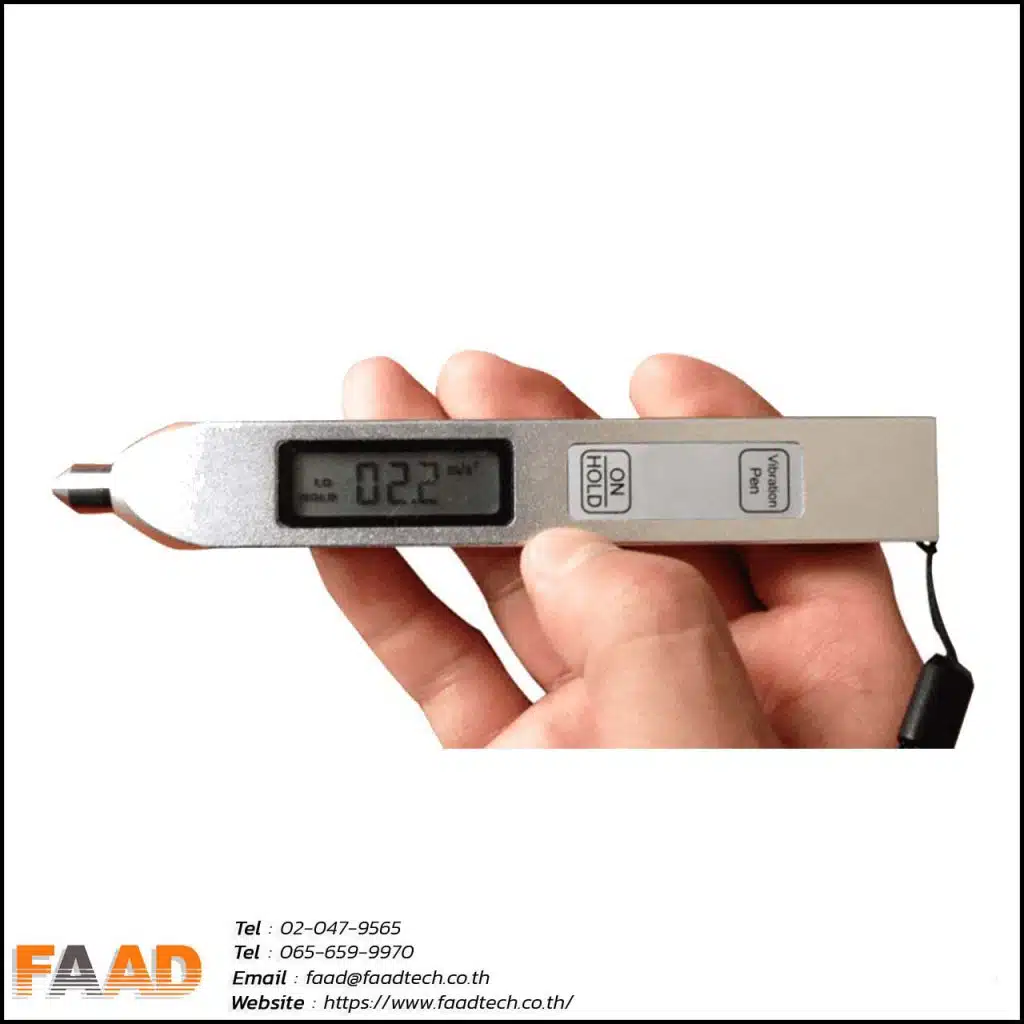

Portable Vibration Meter

This vibration meter is used to analyze the input signal. Results include RMS Velocity, peak-peak value, displacement value, Acceleration, or Real-time Spectral.

This vibration meter is used to measure the error. of motors, electric fans, pumps, air compressors machine tools, etc. urgently and quickly

The vibration meter is used for maximum acceleration data. RMS Velocity Data and Displacement Peak-Peak Data Measurement

This vibration meter is used for measuring the error. of motors, electric fans, pumps, air compressors machine tools and others

Bearing Defender It takes only 10 seconds to collect, process and display the measured values in all three axes. The bearing’s full vibration readings are further shown on the information page.

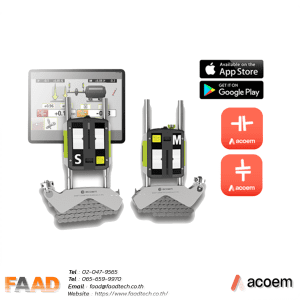

Falcon : This can be set up in less than 2 minutes. It can do Shaft alignment, Balance, Vibration. High resolution FFT and time waveform and Vibration Sensor.

SMC : Able to check the condition of the rotary shaft machine as needed within a few minutes, both Vibration and Balance

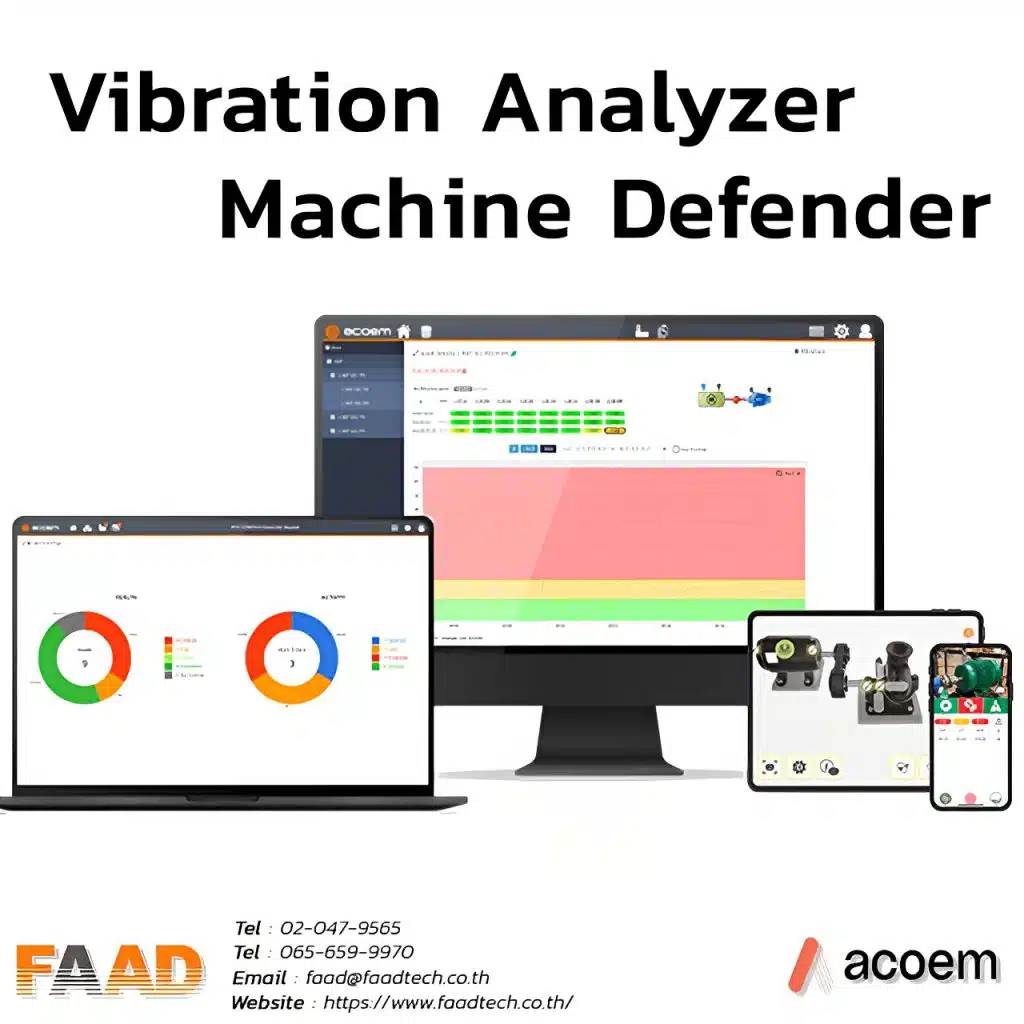

Vibration analyzer MD : It is an automatic vibration analysis tool. Data is delivered to your tablet in seconds with Acoem’s proprietary AI, delivering fast, relevant results.

การเก็บข้อมูล แบบ Online

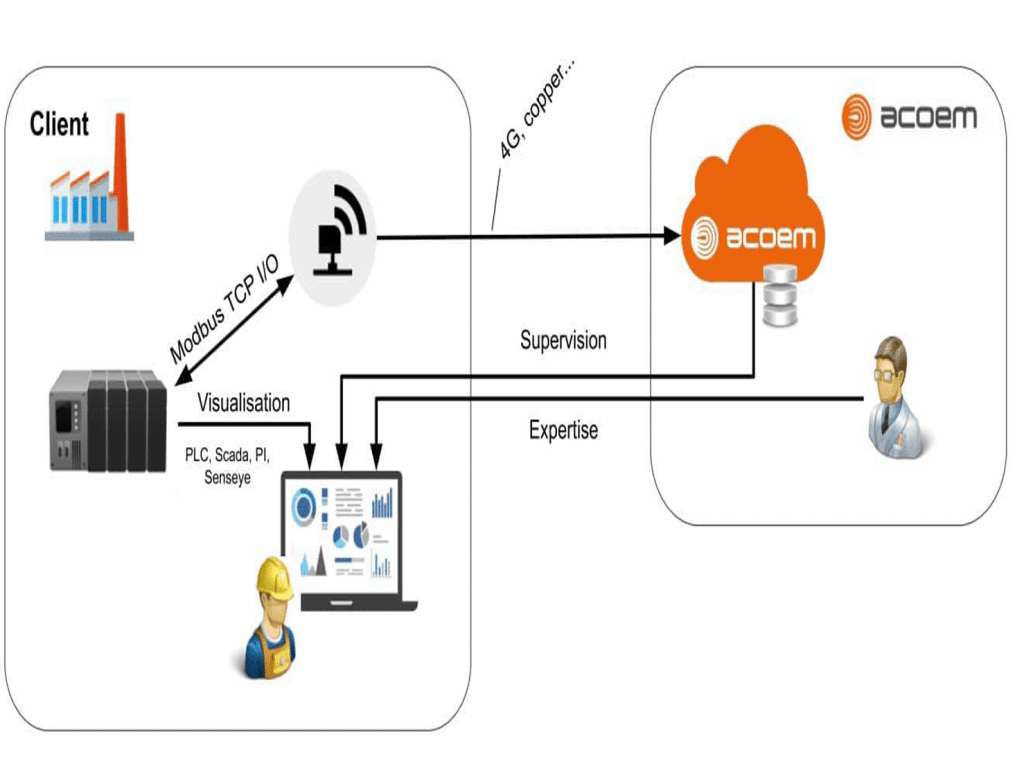

AI will help in analyzing machine problems 1 time a day for up to 3 axes at once.

Then convert the wireless signal to the Gateway, after which the Gateway forwards to the screen. and store the data on the Cloud, Server or Computer where the user wants to store various Vibation data.

The position where the vibration sensor head will be attached will be the position of the rotating machine or the position of the motor that needs to measure the health of the machine, because in the machine, the bearing or bearing will be the heart of the machine that works the hardest. In which most problems are damaged, they often show symptoms (indicate) at this point first.

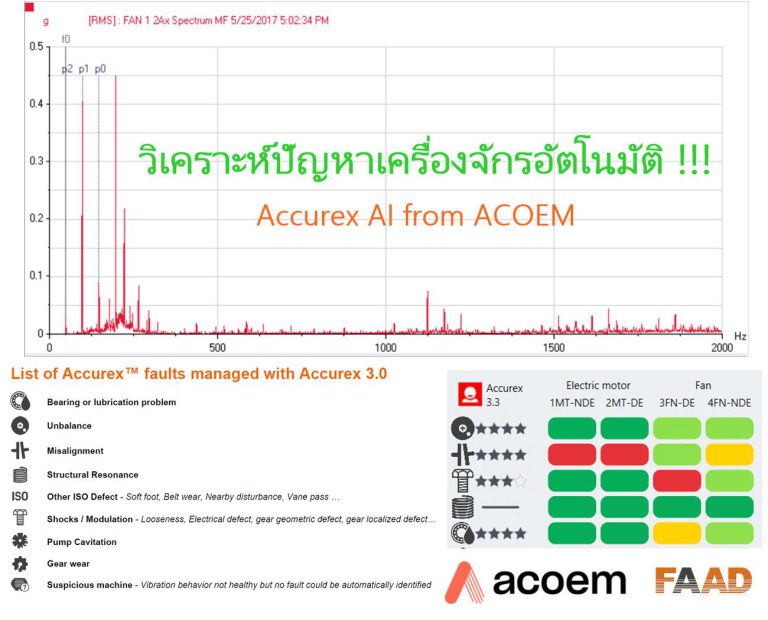

Analyzer chart

Online vibration meter

Real time monitoring : Vibration MVX You can check the condition of the machine in real time and can also analyze bearing problems. both low frequency and high frequency

Wireless online vibration sensor : EAGLE is a wireless condition monitoring system for rotary shaft machinery To automatically measure vibration simultaneously in all three axes with temperature monitoring of bearings

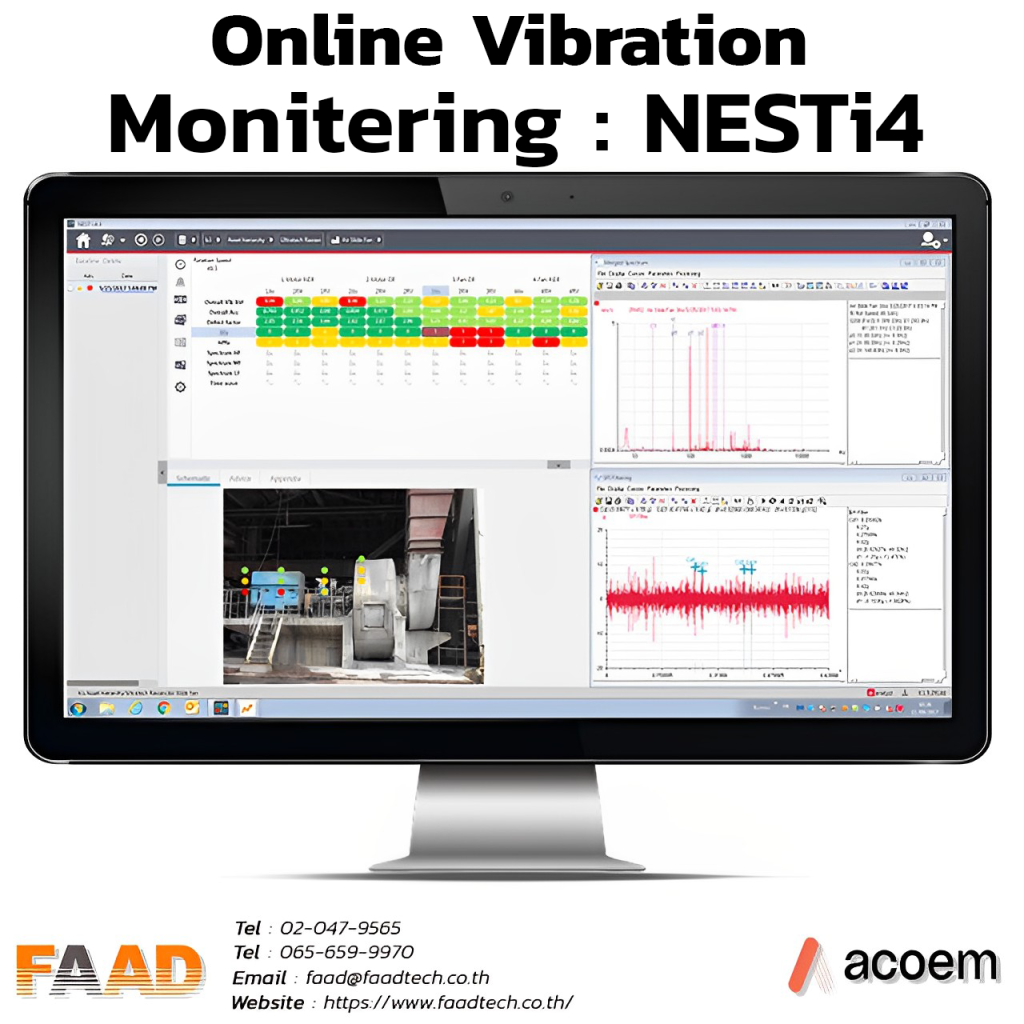

Nesti4 : It is a software that works with Both Acoem products, Falcon and Eagle, vibration measurement systems. and temperature with wireless sensors (vibration sensor) and many other systems.

Wireless vibration Is another thing that can maintain the reliability of the factory very well. Wireless online vibration monitoring is considered a condition base maintenance and a form of Predictive maintenance.

Wireless online vibration monitoring is that we bring the Sensor to measure the vibration by installing it on the machine all the time The vibration value will be stored all the time. And will process the data with FFT format and then transmit the wireless signal through the Gateway, after which the Gateway forwards to the screen. And continue to store data on Computer, Server or Cloud

Accurex is an AI from ACOEM that helps you diagnose machine problems. Whether it is an issue of Unbalanced, Misalignment, Bearing Defect or other problems caused by Vibration, it can be accurately analyzed.

the measurement of machine vibration is very important. Because it allows us to know the problems of the current machine before it breaks down. The type of vibration measurement system can be divided into 3 main types according to the frequency of collecting values as follows:

“Offline” infrequent data collection collection maybe once a month once a week by allowing people to hold a vibration meter to measure at the site Suitable for innocuous and easily accessible spots.

“Semi-Online” collects values here and there once a day, once an hour, then you need to measure its certainty (Wireless vibration sensor), track on site and view data through a computer. Reaching a point where people have access and are at high risk or want to collect more value.

“Online” collects values in Realtime every second, suitable for very important machines. It is a wired sensor (Wireless vibration sensor) attached to the work site and can view data through a computer.

Therefore, we should choose the equipment that best suits our needs for the greatest value in use.

FAAD has vibration measurement equipment available in both Offline (Falcon), Semi-Online (Eagle), Online (MVX) to thoroughly meet all customer needs.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[ASH456] – HIGH TEMP ACCELEROMETER [ASH456] – HIGH TEMP ACCELEROMETER](https://www.faadtech.co.th/wp-content/uploads/2024/07/dASH456-2-600x600.jpg.webp)