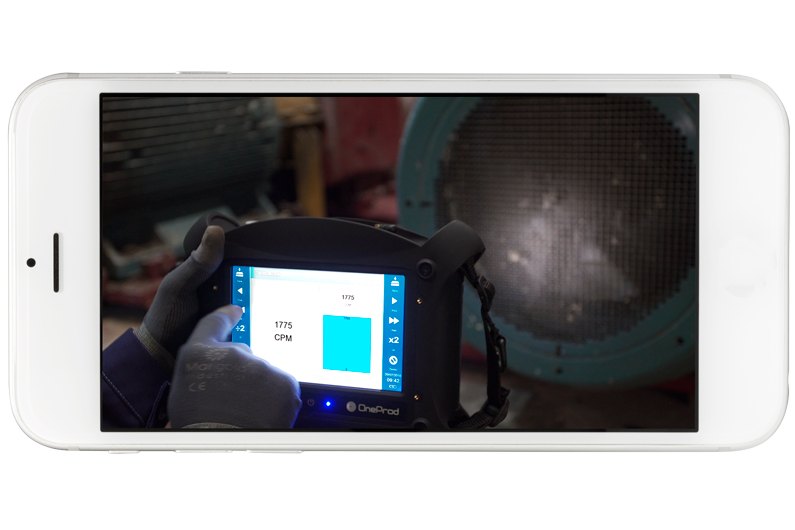

FALCON – Vibration Analyzer

Packing in Acoem’s 30 years of experience in the condition monitoring of rotating equipment, FALCON is an innovative tool for vibration measurement and analysis that puts condition-based maintenance within the grasp of all users.

All-in-one

FALCON packs in innovative features never previously seen in a single device:

patented three-axis wireless sensor, taking simultaneous vibration measurements in all directions

built-in strobe light for rotation speed measurement

built in laser pyrometer for bearing temperature measurement

built in camera for easy machine identification, sensor positioning, and report illustration

embedded patented Accurex™ automatic diagnostic

4 analog channels for synchronous measurement, in addition to the trigger input

Accurex™ automatic diagnostic

FALCON allows making immediate use of the benefits of condition based maintenance: the patented Accurex™ automatic diagnostic works instantly based on the first measurement. Faults detected are available right in front of the machine such enabling interaction with the user (bearing lubrication, temperature control…) and optimization of the maintenance process.

FALCON allows making immediate use of the benefits of condition based maintenance: the patented Accurex™ automatic diagnostic works instantly based on the first measurement. Faults detected are available right in front of the machine such enabling interaction with the user (bearing lubrication, temperature control…) and optimization of the maintenance process.

Automatic measurement setup

FALCON is within everyone’s grasp. What was once tedious is now a real child’s play, as configuration is carried out by providing a simple machine description of the machine’s kinematics via a built-in visual interface. Any rotating asset can now be setup within less than 2 minutes. All vibration measurement needed are there: ISO 10816 velocity, overall acceleration, Acoem bearing Defect Factor™, high resolution FFT and time waveform, and adding customized parameters can be done in only few clicks and on the whole database. Building a database has never been so easy!

Measurement productivity

The wireless three-axis sensor and real-time processing capabilities literally cut times of vibration measurements: 8 seconds per bearing typical for measuring all X Y and Z directions with the highest quality set of vibration data. With the use of pictures, the machine identification among a route has never been so easy: the user navigates on FALCON’s large colorful touchscreen from the top view of the plant to the sensor position picture on the machine.

FALCON reduces the time and costs needed for on-site intervention to the absolute minimum. At the scale of a plant, FALCON really stands out.

Reliable by design

FALCON was designed for uncompromised industrial use in the harshest settings:

ATEX Zone 2

IP65

Withstands a 1.2-meter drop.

FALCON comes with a large color touch screen, which can even be used with safety gloves, a rubber grip for better handling and anti-shock resistance. The lack of cable makes the user working in safe condition, within a range of 10 to 20m between the wireless sensor and the unit: measurements can be done under protective casings or behind doors, and the user no longer has to stay close to the machine in hot environments.

Great communicator

FALCON incorporates all modes of communication:

Wireless WiFi communication with the three-axis vibration sensor

- Uploading/downloading of data by USB, Ethernet, Internet, standard WiFi protocol

- Remote route exchange by email

- Cloud access to the ACOEM hosted platform

The FALCON collection and vibration analysis tool communicates data to the condition based maintenance platform equipped with the powerful NEST software, so that the data can be stored, analyzed, and reports automatically published.

Vibration Meter : Falcon

OneproD Vibration Analyzer

Vibration : Falcon : A portable vibration measuring instrument with a wide range of functions and features. With automatic analysis system, Wireless sensor that can analyze values up to three axes (X, Y, Z) from just 1 measurement order, making checking machine conditions more convenient, faster and more efficient.

Suitable as a tool used to test the vibration of objects or machines. This vibration can indicate that the machine is balanced or Balance, which is expressed as Displacement,Velocity,Acceleration Some models can display values in Fourier transform. The Vibration Falcon is a tool that makes measuring distances or lengths easier.

Vibration : Falcon

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.