เครื่องมือตั้งศูนย์เพลาด้วยเลเซอร์ (Laser Shaft Alignment) – Acoem Fixturlaser

Laser Shaft Alignment

เครื่องมือตั้งศูนย์เพลาด้วยเลเซอร์ (Laser Shaft Alignment) โดย Acoem Fixturlaser

Shaft alignment

The received resource (Center of Rotation) of the driven and driven axles is in the same position for the time of rotation while the centerless does what is required for the machine. To obtain an acceptable eccentricity of the machine, since the former includes the alignment method before starting, the use of rulers and feeler gauges are all help with less resources requiring experience. These will lead to the next step is to compare dial gauges (diameters) and plus user testing until the experts before sessions often encounter Bar Sag problems that often down or the stiffness of the various parts that are available. Here are the frequently available readings. Nowadays, laser centering in Brazil is another way to use, which makes it much easier to use than dial gauges.

What about Shaft Alignment ?

Around the world, it is necessary to operate a large number of rotary machines such as millions of motors and pumps and other machines. To transmit power from the motor through coupling (Coupling), which when misalignment occurs, will cause stress (Strain) on both sides of the shaft until various abnormalities such as the workload of various parts such as seals (Seal) increases to the point that it may cause damage, bearing damage, machine performance decreases, Vibration increases and heat buildup occurs. which are all damage that no one wants to happen because in addition to having to pay for repairs There is also the cost of lost production time. Therefore, a good shaft alignment It is another way to avoid these problems.

What is Dial Indicator ?

Manual calculation and skillful use

which we can fix by laser shaft alignment laser shaft alignment

. Why Should to use Laser shaft alignment with FAADTECH? .

Why use laser shaft alignment tools from ACOEM ? Because we have experience in shaft alignment. We have designed technology to suit users. from beginner level up to expert level In order to work easily and quickly, FAADTECH is an official distributor with ACOEM in the RT300 box. What’s in 1 box? Let’s see.

Unboxing Laser shaft alignment RT-300

Confidence.

Make smarter decisions.

RT-300 delivers confidence at every level.

Whether you’re a maintenance tech, reliability engineer, plant manager or manufacturing engineer, RT-300 will keep your machinery running at peak performance. RT-300 uses “guide me” technology that’s intuitive and requires little to no training so that your team members can start using the ecosystem on day one.

By taking the guesswork out of the decision-making, your team can start making smarter choices to keep machines running at optimum levels. Choose how often you want to run diagnostic tests: quarterly, monthly, weekly and if necessary, daily, so that you can keep machines running at optimum levels..

Access

Cloud-Based Ecosystem

Making an informed decision is right at your fingertips.

All apps are connected to the ACOEM cloud, which means that you have instant access to vital information. This allows you to make faster, more-informed decisions.

Connectivity

Share secured data easily.

RT-300’s ecosystem of collaborative tools allows everyone who needs information to share synchronized machine setups. Whether it’s technicians on the ground, remote supervisors, or even stakeholders halfway around the world, information is just a click away.

Instantly share updates, maintenance job notifications, field info and assets setup. This means teams are constantly connected and are able to make shared decisions.

Empowered by Acoem technology

Self-Guided Apps

All of RT-300’s apps, tools and hardware are easy-to-use and self-guided, so teams don’t waste time setting up complicated systems. Once the device is activated, the diagnostics take care of themselves — and teams can spend their time correcting the issue, if there is one, or focusing their efforts on more critical machines.

Training Videos

All of your tablet-based display units will come preloaded with access to our how-to training videos.

Techincal Support

For technical support, please call +666-5659-9970

Laser shaft alignment NXA PRO

The sensor of the (wireless vibration sensor) NXA Pro has been improved to the 2nd generation. This sensor version has improved resistance to harmful external factors such as vibration. and ambient light And provides the most accurate and accurate measurements compared to other systems Laser Shaft Alignment NXA PRO is available for trial use for on-site DEMO work.

Easy to work, use only 1 measurement and can fix the job immediately

adjust level Vertical / Horizontal ได้ด้วยฟังก์ชัน VertiZontal Moves™

The results are clear and accurate with a smart sensor.

A PDF report shows the alignment process. results in detail

.

There is also a Vibration Filter.This will help filter the vibration signal. that can be disturbed by the surrounding machines as well

Price starts at only 5xx,xxx Bath.

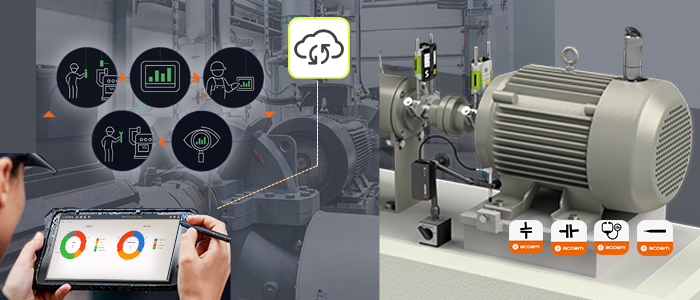

Laser shaft alignment RT-300

RT-300 Machine condition inspection tool New world technology

It is a One Stop Machine, complete in one machine, easy to carry, inexpensive, with service from FAADTECH.

Store the value only once and get all 3 axes.

Support cloud with intelligent AI analytics power.

Fast, instant, within 9 seconds and also helps prioritize the problem.

– Analyze machine condition well, fast, support Cloud system

– ensure safety With clear results, Accux AI helps analyze problems in detail.

– Check the readiness of the machine before maintenance. This is very important with the Pre Alignment, Laser Shaft Alignment and Vibration Analyzer and Diagnostic functions.

– Compatible with all types of machines in your industry. modern update

– Maintenance engineers can use it easily through an application on their personal smartphone or iPad, even if they are not experts.

– PDF report of the machine condition check and use it right away!

Price starts at only 3xx,xxx Bath.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.