How to Slove Partial Discharge

PARTIAL DISCHARGE ?

Type Partial discharge

- Corona Discharge: The most common form of partial discharge. This occurs when a direct discharge into the air emanates from the sharp surface of the conductor. This is what causes sound and radio frequency emissions.

- Arcing Discharge : An arc discharge is a long-term electrical discharge caused by the electrical decomposition of a gas.

- Surface Discharge : When the discharge travels along the surface of the insulator. This is called surface discharge. or surface tracking It is one of the causes of Pratial discharge that causes the most damage. Contamination and weathering of insulating surfaces are two of the most common causes of surface discharge in medium and high voltage equipment. This type of discharge occurs when the insulation breaks. This is usually caused by high humidity or poor maintenance.

- Void (internal) Discharge: Most commonly caused by defects in the solid insulation of cables and bushings, insulating connections, GIS, etc. Void (internal) discharges are extremely damaging to the insulation and generally expand. The next one until it causes damage to the point where it can’t be used anymore.

Signal characteristics of Partial discharge

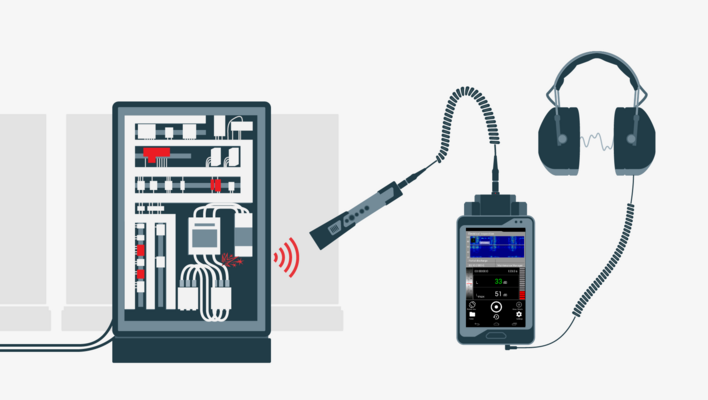

You can protect Before there is a problem of partial discharge, you can use ultrasonic tools to check with sound. Before the electricity break out the insulation Until the problem of discharging

How to prevent partial discharge

1. Regular inspections: Conduct regular inspections to identify signs of partial discharge, such as abnormal noises. abnormal heat or the smell of ozone

2. Quality control: Ensure high quality insulating materials and manufacturing processes to minimize the occurrence of defects that trigger partial discharge.

3. Voltage Optimization: Keep the voltage level within safe limits. To prevent excessive electrical stress on the insulation system.

4. Condition monitoring: Use a continuous monitoring system to detect partial discharge early. In order to be able to intervene and take preventive measures in a timely manner.

5. Periodic Maintenance: Clean and maintain electrical equipment regularly to reduce contamination that may trigger partial discharge.

Causes of partial discharge:

1. Voltage stress: Excessive voltage levels may cause the electric field strength to exceed the ability of the insulation to withstand, leading to partial discharge.

2. Insulation Defects: Inadequate Insulation: Voids, gas bubbles, or impurities within the insulating material can create weak points that are prone to partial discharge.

3. Age and deterioration: Over time The insulating material may deteriorate. Decreased ability to cope with electrical stress and increases the chance of partial discharge

4. Mechanical stress: Physical stress on the insulation, such as vibration or excessive pressure. May impair insulation integrity and promote partial discharge.

Tools to assist in the detection of partial discharge

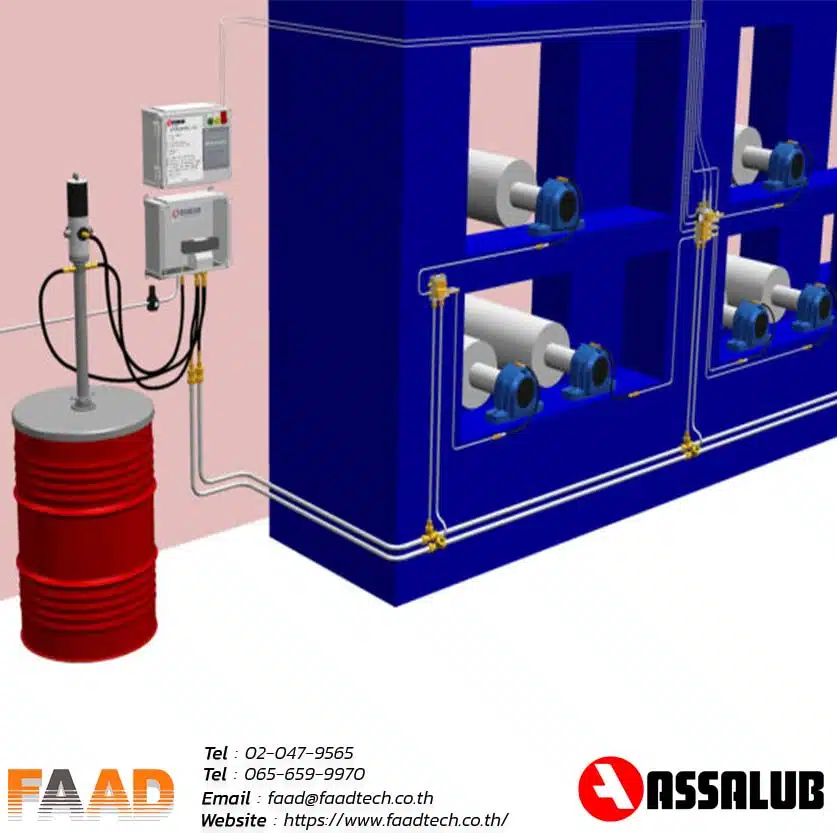

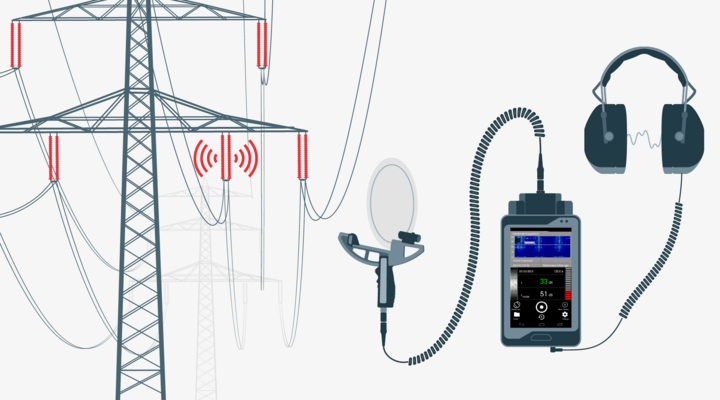

In conjunction with the SONAPHONE ultrasonic testing equipment, the SONOSPOT parabolic dish is used to detect hard-to-reach or distant damage. such as on power transmission and distribution lines. The high sensitivity and precise orientation of the sensor enable the detection of electrical partial discharges and insulation damage such as medium voltage electrical equipment (Medium-Voltage) or switchgear Increased tendency of partial discharge can lead to widespread damage in the insulators.

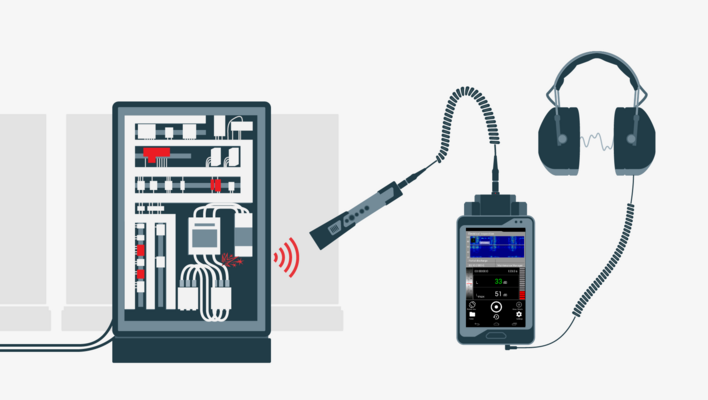

Regular inspections of electrical equipment are essential for preventive maintenance. SONAPHONE devices can be used to detect and classify the severity of corona, tracking and arcing problems. For both high, medium and low voltage equipment to monitor open or closed electrical systems. To inspect switching cabinets, control boxes, relays, transformers, insulators, etc.

Ultrasonic Leak Detector

Leak Detector Acoustic Imager | Cry Sound CRY2624 is an explosion-proof instrument suitable for petrochemical and heavy-duty industries.

Analytics and Reports

Template-based processing and recording of data, waveforms,spectra,spectrograms is supported by CRYSOUND report analysis tool software, generating ISO 50001 compliant, editable protocols in Excel format.

PD Detection & PD Type Identification

Partial discharges can be detected before more serious faults would occur, even before a thermal camera would detect them.

Ultrasonic leak detector SONAPHONE Make a report to calculate the amount of air leakage and the cost automatically.

Ultrasonic Leak Detector SONASCREEN Make a report to calculate the amount of air leakage and the cost automatically. You can see the leak point with your eyes.

Leak detector With ultrasonic SONAPHONE POCKET, check the air leak with ultrasonic, easy to use, easy to carry.

Advantages Of Ultrasonic Leak Detection

This ensures all major aspects of pulley misalignment are resolved. This belt alignment tool is so easy to use, a single operator can perform the pulley or belt alignment task in minutes with no training! Comes in its own durable carrying case.

Detect leaks in compressed air, inert gas and vacuum systems

Save up to 35 % of the energy costs associated with the use of a compressor

Patent-pending method for leak classification and evaluation in l/min

LeakExpert: Specific app for leak detection and classification for SONAPHONE

Generate leak reports

LEAKEXPERT

Specific app for leak detection and classification

Leak Detectors

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.