How To Check Or Analyze The Quality of oil

Prologue

Oil analysis It important role in maintaining the efficiency and longevity of machines and engines. By checking for foreign substances in the oil regularly. You can identify potential problems before they escalate into expensive repairs or breakdowns. In this comprehensive guide We will explore the importance of oil analysis. and provides step-by-step instructions on how to detect foreign substances in oil.

Tools used for inspection

Tools used in checking and analyzing oil conditions. FAADTECH has a team and user manual for customers who need training.

Let to Know about oil analysis

Oil analysis is a proactive maintenance technique. That involves examining oil samples to assess condition and identify contaminants or wear particles. It provides important insights into the condition of the machine. This helps detect problems such as deterioration of the lubricant. excessive wear and the presence of foreign substances with oil analysis You can make informed decisions about your maintenance schedule. Oil change period and equipment repair Regular oil analysis can improve equipment reliability. Reduce downtime and can extend the life of the machine

The importance of checking for counterfeit substances

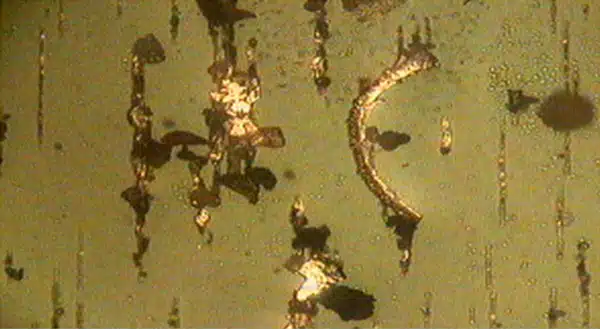

Counterfeit substances in oil can be dangerous to the performance and lifespan of equipment. Contaminants such as dirt, water, metal particles, and contaminants can cause corrosion, erosion, reduced lubricity, and even catastrophic failure. Identifying and managing these contaminants early on will allow you to prevent costly repairs and ensure the efficient operation of machinery. Regularly checking for counterfeit substances in oil is crucial for maintaining optimal equipment performance and minimizing the risk of unforeseen damage.

Basic steps for checking the quality of oil

Oil analysis is key to ensuring the longevity and performance of your equipment. Start implementing these practices today to protect your machines from potential problems.

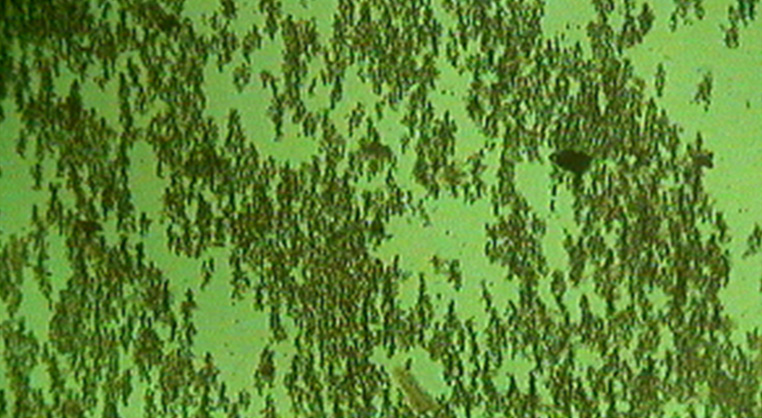

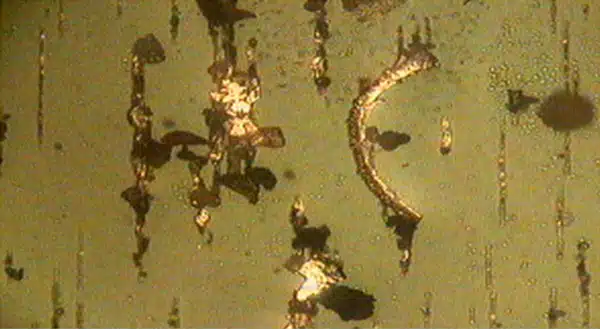

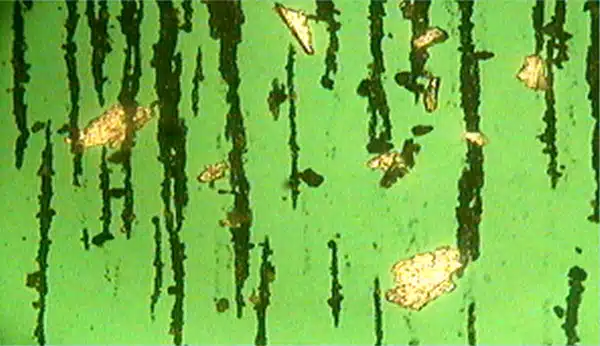

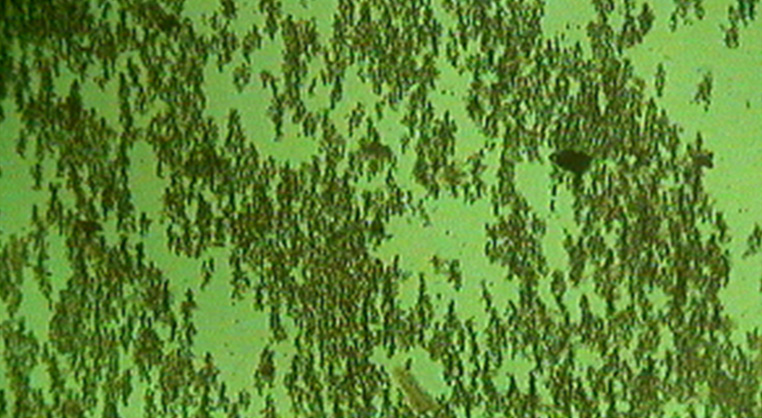

Ex : Impurities in oil

Step 1: Prepare equipment and tools necessary for use

Oil analysis You will need a clean sample bottle. Sampling pump or tube, gloves, and safety glasses. Including equipment used to inspect or analyze the quality of oil, such as Oil Sensor Of Moisture Content | YTS-W-1 , Ferrous debris monitor | YTD-2 , etc. and must ensure that the sampling equipment is not contaminated before brought in for inspection

Step 2: Select the oil sample to be examined.

Select representative sampling points in the oil system. It should be downstream of the filter. Avoid sampling from drains or low points. This is because there may be higher concentrations of contaminants.

Step 3: Analyze data from the samples taken for inspection.

Once you receive the analysis report Please check carefully. Pay attention to parameters such as particle count, viscosity, water content and metal wear level. Compare results with limits recommended by the device manufacturer or industry standards.

According to the analysis report Determine if any corrective action is required. Consult with a maintenance professional or the equipment manufacturer to resolve any identified issues. Use recommended maintenance procedures, such as changing the engine oil. Change the filter. or additional verification if necessary.

Oil quality analysis tools

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.