How to check | Bearing Inspection

What are ball bearings and what do they do?

Ball bearings generally consist of Round steel pellets are a component. It consists of a series of small steel balls contained within a ring. Used to reduce friction on various crankshafts. between moving parts and helps to rotate smoothly

Type of bearing

Ball Bearing

Characteristics of ball bearings: spherical ball bearings that are packed inside the ball bearing cage. Moves in the middle between the outer rings. and inner ring Serves to support high-speed movement. and reduce friction between machine shafts Often used in radial load applications.

Roller bearing

Characteristics of roller bearings The cylindrical ball bearing is also contained within the bearing cage. which moves between the top ring and bottom ring, has the same function as Ball bearings, but Roller bearings are commonly used to receive axial force. which can withstand force better than spherical bearings

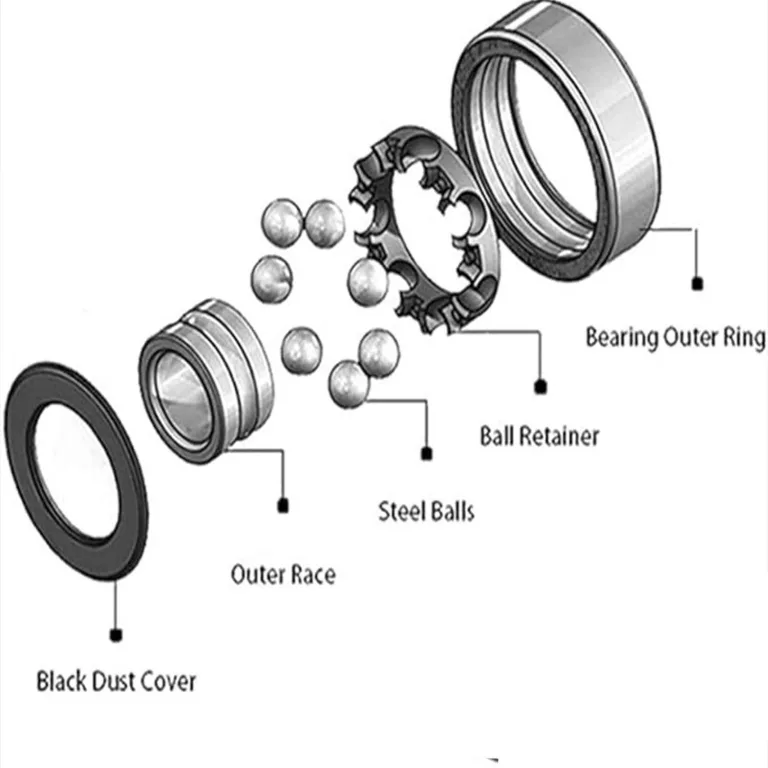

Components of ball bearings

- Outer ring serves to support the internal ball bearings, both spherical. and cylindrical

- Roller pellets (Ball or Roller) are mainly of 2 types: round and cylindrical, serving to support weight and Reduce friction on the spindle

- The ball cage (Separator or Retainer) serves to contain the ball bearings and sets the distance between the ball bearings to be the same distance.

- Inner ring serves to prevent the rollers from coming into direct contact with the shaft.

- Dust Cover prevents dirt from entering the inside of the part.

Brief components of a ball bearing

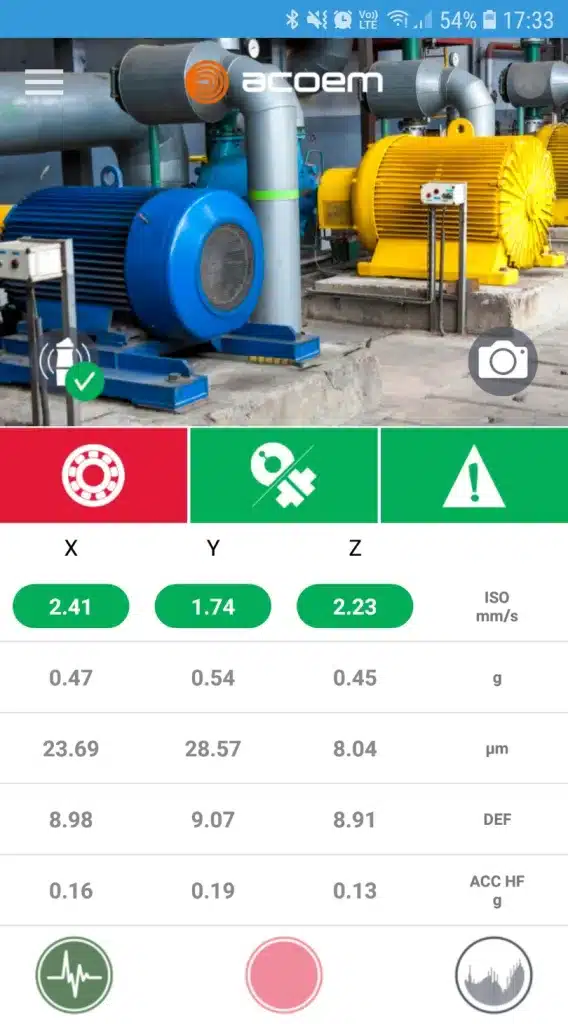

Status received from the machine: Bearing Defender

First, let’s understand about Bearing Defender (BD). Bearing Defender was developed by Acoem as a vibration analysis tool. Designed for professionals, it can be used by both experts and non-professionals alike. Similar to ‘Vib pens’, it doesn’t just let you listen to the sound of the bullet as you collect data. But it is also possible to identify specific faults based on pre-defined vibration indicators through a user-friendly interface.

The screen Bearing Defender

Indicator | BD

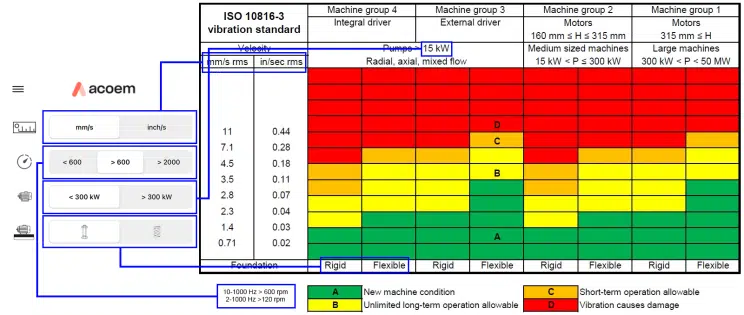

After completing the measurement and reviewing the data, Bearing Defender will display the measured data, such as commonly called indicators. That vibration velocity is calculated according to ISO 10816-3 and detection sensitivity will vary depending on your measurement setup. The fastest possible is Measure analytical results in just 10 seconds from a 3-axis wireless sensor.

Status value

First of all, when first measuring, you must know that velocity is an indicator of a machine that is working too hard. and when the speed level is abnormal Types of failures that can be detected by Bearing Defender (BD) machines such as:

- Imbalance

- Oil whirl

- Misalignment

- Coupling issues

- Looseness

- Gear mesh (slow)

- Blade passing (slow)

The screen Bearing Defender

Acceleration (g)

Second set of information is the status value that we will receive is acceleration in g-force. This measurement is a basic measurement of the instrument because the sensor is an accelerometer. The frequency levels examined in frequencies from 2 to 20,000 Hz RMS are not the same as standard speeds. preset to notify when a certain level is reached The stat in g represents the damage the machine is taking. And these levels vary greatly depending on the load and speed of the machine being monitored. Accelerometers are very useful in detecting high frequency anomalies such as these:

- Bearing failures

- Lubrication problems

- Gear mesh (fast)

- Cavitation

- Turbulences

- Friction

- Blade passing (fast)

Displacement (micron)

The next information is the displacement. with units of microns or millimeters. Peak-to-Peak detection is generally used and the setup is also ISO 10816-3 compliant.

Displacement measurement generally shows the state value of It reflects mechanical stress and elevated levels can be a sign of problems such as:

-

- Imbalance

- Oil whirl

- Whip

- Coupling malfunctions

- Loosening

Status : DEF

The DEF or Bearing defect factor is an algorithm developed by Acoem in the 1970s. DEF utilizes various signal processing techniques, including high-frequency detection and peak factor, to provide users with a simple and effective indicator.

In the latest update of the application on IOS and Android (v1.51), a new feature has been introduced that adjusts the DEF alarm levels based on the sensor mounting type on the bearing.

Based on your choice, (Left = installation on adhesive pad, Right = installation with magnet ), the alarm/danger thresholds will be set at 6 / 9 for adhesive pad mounting and 4 / 6 for magnet mount.

ACC HF (g)

The final set of data that Bearing Defender provides is ACC HF, which is primarily high-frequency acceleration detection. ACC HF has a frequency range between 3 kHz and 20 kHz with RMS amplitude detection and can be used for monitoring and related purposes. Liquid used to lubricate ball bearings

Finally, the Bearing Defender is an entry-level instrument primarily designed for non-experts in vibration analysis. Yet it offers considerable flexibility by covering the majority of the range of vibration faults sought (2-20 kHz) with a automatic defect detection and spectrum capabilities.

Bearing Defender It takes only 10 seconds to collect, process and display the measured values in all three axes. The bearing’s full vibration readings are further shown on the information page.

Vibration analyzer MD : It is an automatic vibration analysis tool. Data is delivered to your tablet in seconds with Acoem’s proprietary AI, delivering fast, relevant results.

SMC : Able to check the condition of the rotary shaft machine as needed within a few minutes, both Vibration and Balance

Falcon : Ultimate is a vibration engine with AI assisted collecting. Troubleshooting includes wireless sensors and Balance applications, FRF/ODS module and Run-up Coast Down module.

Results in 10 seconds

The Bearing Defender only takes 10s to capture, process and display the data resulting from the measurement in the three directions. A full vibration reading of the bearing is displayed in addition to the smart indicators:

Vibration velocity with alarms according to the ISO10816-3 standard

Full range Acceleration

Displacement

Bearing Defect Factor™ value

High Frequency acceleration value

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.