Coating Thickness Gauge

A Coating Thickness Gauge is a device used to measure the thickness of coatings or protective layers applied to the surface of various materials or products such as steel, aluminum, plastic, machinery, or automobiles. The primary objective of using a Coating Thickness Gauge is to control the quality of coatings and possible dilutions. Typically, the thickness of coatings or layers is specified for each task or application that requires accurate results in controlling the quality of the product or material. Measuring the thickness of coatings is crucial in many industries such as steel, automotive, and those related to corrosion resistance or chemical resistance. The main goal of measuring thickness is to prevent corrosion, peeling, or other damage that may occur to the surface of the material by verifying whether the thickness of the coating or layer meets the specified standards.

These devices are commonly used in engineering applications such as manufacturing, construction, maintenance, as well as in laboratory coating or machinery rooms where precise measurement of thickness is required to meet specified standards.

COATING THICKNESS

GAUGE METER

3000 PTS

COATING THICKNESS

GAUGE METER

DCF 2000

COATING THICKNESS

GAUGE METER

3000 EZ

COATING THICKNESS

GAUGE METER

MINITEST 420

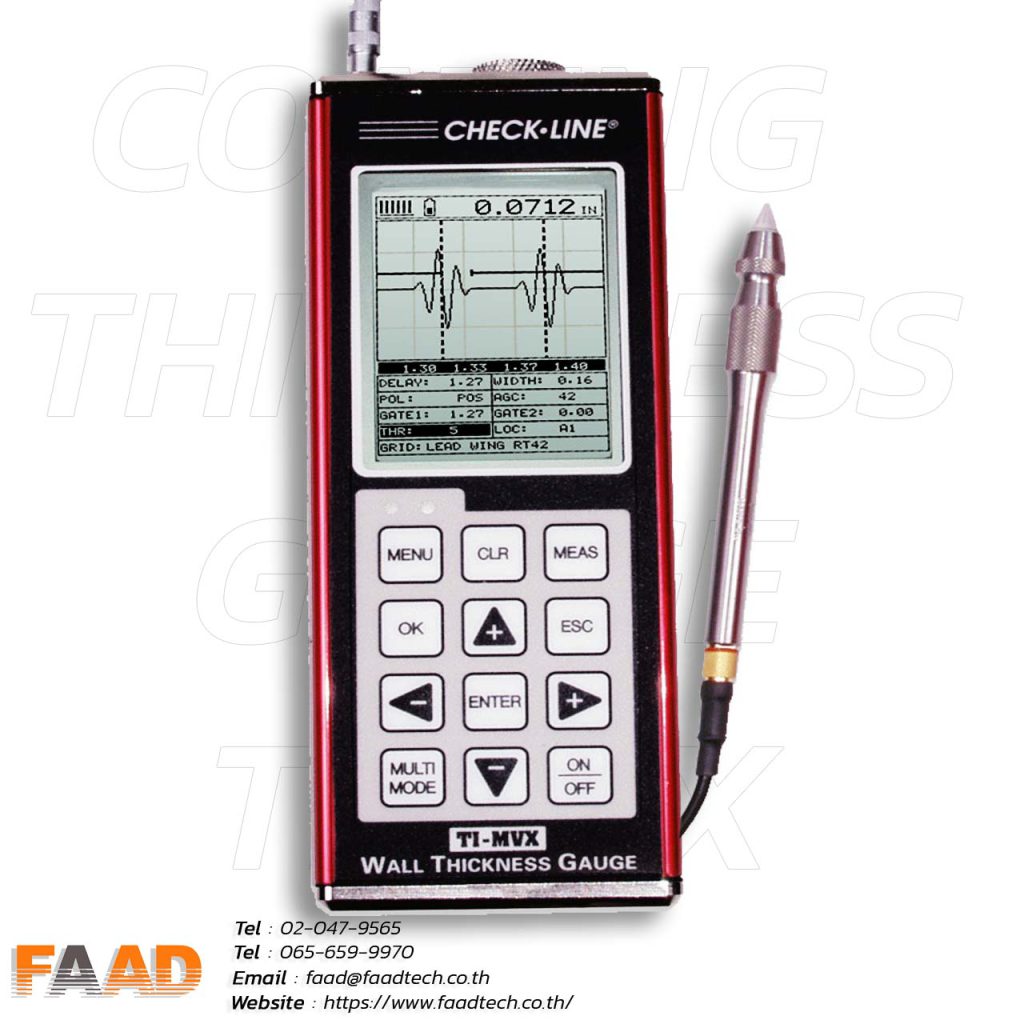

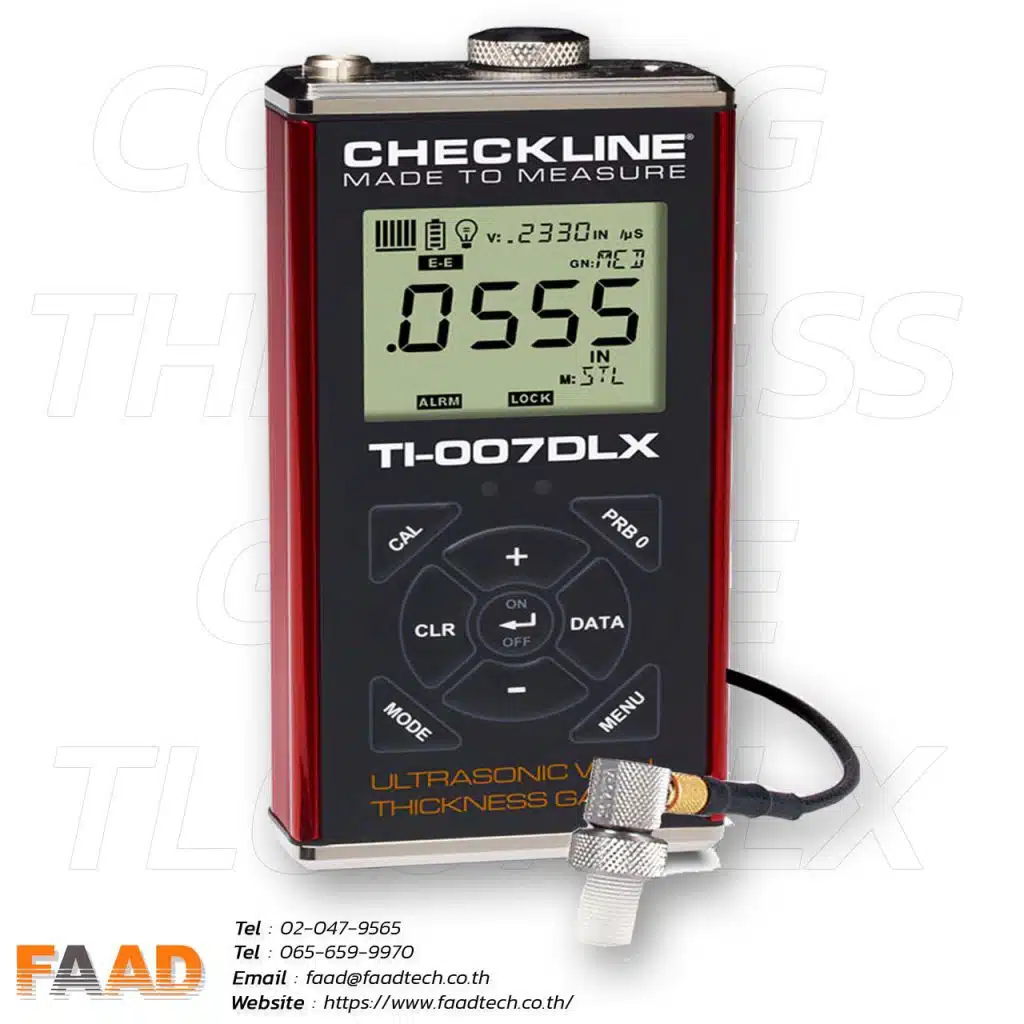

COATING THICKNESS

GAUGE METER

TL – 25DLX

The importance of using Thickness Gauge

The surface thickness gauge is an extremely important device in various aspects, such as:

- Safety of products: Controlling the thickness of coatings or dilutions possible on products, such as coatings, paints, or other coatings, can help reduce the risk of errors or accidents in the use of those products by preventing material leakage or inadequate surface roughness.

- Product quality: Controlling the thickness of tools or coatings to an appropriate thickness can help ensure good product quality by reducing damage to materials or products resulting from errors in thickness control.

- Resource conservation: Controlling the thickness of coatings or dilutions to meet specified standards can help reduce the use of unnecessary materials and minimize resource losses.

- Prevention of corrosion or surface damage: Coatings or dilutions that are inadequately thick may cause damage to the material surface through corrosion or abrasion. Measuring surface thickness helps prevent such problems effectively.

- Quality control and data management: Using surface thickness measurement devices helps record data and track the ability to control product quality. Additionally, it aids in generating reliable production reports and operations management.

In summary, surface thickness measurement devices play a crucial role in controlling quality and efficiency in various aspects of manufacturing processes and material usage, particularly in industries that require high levels of quality control and accuracy, such as automotive, machinery manufacturing, and high-standard product creation.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.