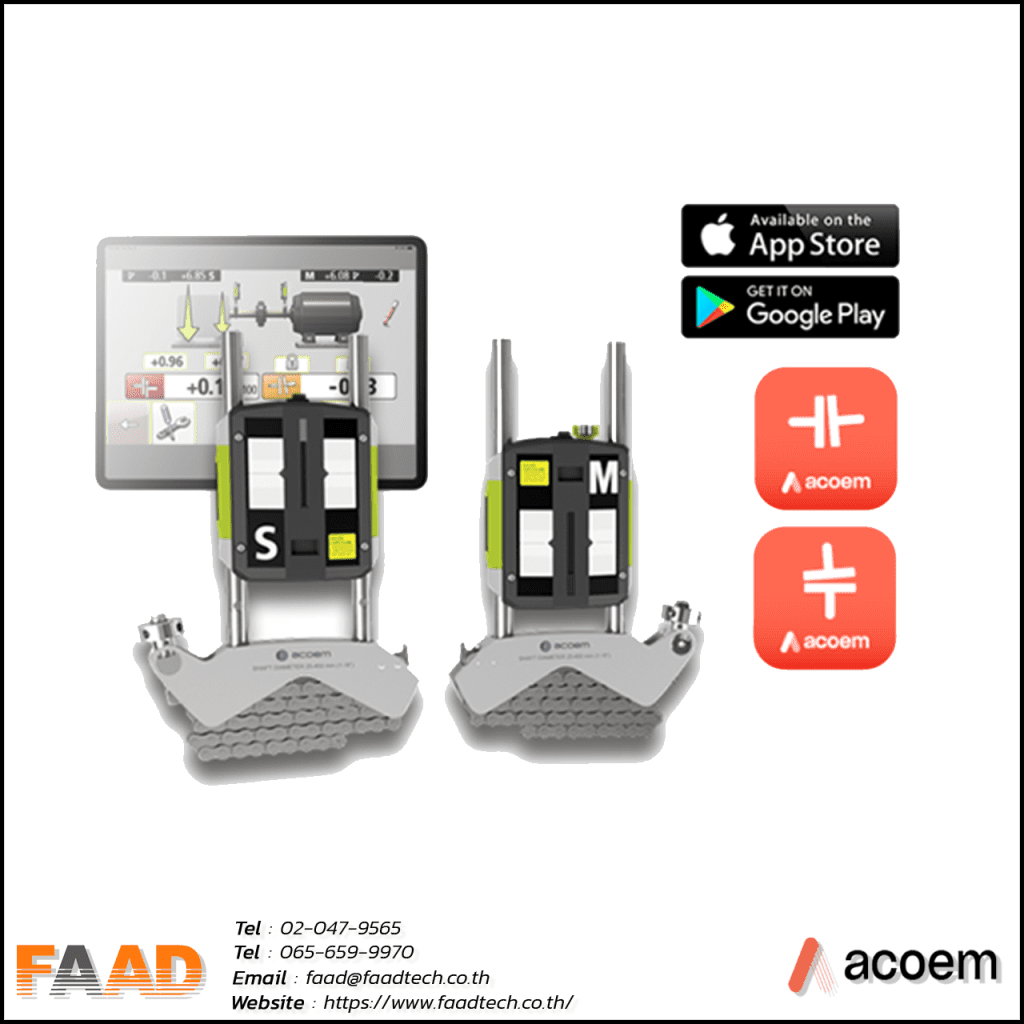

Laser Shaft alignment – AT 200

✅ The smart app-based shaft alignment solution 📱

This new generation of horizontal & vertical laser shaft alignment solution is the result of almost 40 years of expertise and innovation.

Integrated apps, customized technology features and easy connectivity : the AT-200 leverages technology to enhance your user experience and improve the efficiency of your maintenance teams. Providing unparalleled measurement performance and fast, precision alignment, the AT-200 improve measurement and reporting capabilities, to help you extend every critical machinery’s lifespan

Features

Large 30 mm digital sensor detectors – capacity to handle long measurement distances and large angular misalignment errors

SoftCheck™ – Soft foot detector

SoftCheck™ – Soft foot detectorEasily verify the presence of soft foot to make a reliable alignment

FeetLock™ – Automatic guidance

FeetLock™ – Automatic guidanceGet better automatic guidance for a base-bound or bolt-bound situation

Tolerances – Automatic quality assessment

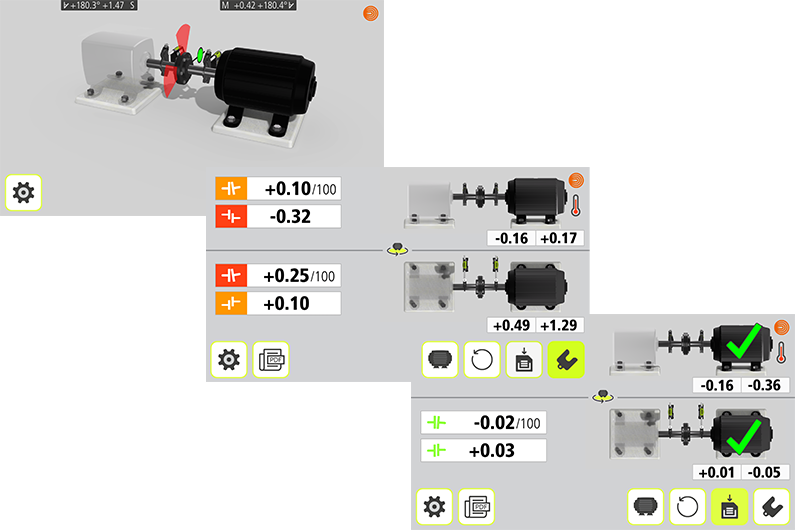

Tolerances – Automatic quality assessment GuideU™ – Intuitive 3D graphical user interface

GuideU™ – Intuitive 3D graphical user interface True Live™ – Real time positioning

True Live™ – Real time positioning Target values – Cold and Hot alignment (optional)

Target values – Cold and Hot alignment (optional)

A complete shaft alignment tool

So much more than an horizontal and vertical laser shaft alignment tool, the AT-200 Toolbox gives you the power to make informed decisions and take corrective maintenance action immediately, straight from your tablet or smartphone :

- Fast and accurate results, powered by intelligent sensor technology

- Easy-of-use, via our shaft alignment apps

- Easy data sharing capabilities thanks to a full integration and connectivity system

The toolbox includes:

- Two smart wireless sensors with their accessories

- Task oriented Horizontal & Vertical shaft alignment mobile apps

- Acoem Cloud connectivity with report storage, trending and work order and sharing capabilities with secure communication (optional)

Improve your maintenance team’s efficiency

Laser Shaft alignment AT-200 improves the user experience of your shaft alignment operations, offering :

- Accessibility and efficiency : wireless, easy to implement, user friendly new technology tools

- Time saving and reliability : quick and easy verification of pre-alignment steps, accelerated handling on standard mobile devices (Free laser App for IOS and Android Devices)

- Fewer errors: optimal visual guidance

- An accelerated decision-making process : instant reporting

Reduce downtime and improve productivity

A complete shaft alignment solution where precision alignment matters. Even the smallest angle of misalignment can drastically reduce the lifespan of rotating machinery by more than 50%. This can be avoided by proactively undertaking precision alignment as part of your maintenance program. Proper alignment practices not only help reduce downtime but also improve productivity.

- Avoid unexpected failures which can causing complete process shutdowns or safety incidents

- Eliminate the root cause of 50% of bearing failures

- Extend the lifetime of your assets and reduce the total costs of ownership

- Reduce energy consumption by up to 10%.

TrueLiveTM

Save time with revolutionized live shaft alignment

An industry-first technology, TrueLive™ functionality ensures that you always know your machine’s exact position. Its two compact smart sensors feature laser beams and inclinometers which monitor both shaft positions simultaneously. Even if you move the machine’s position out of detector range or interrupt the laser beam, the smart sensors will resume with an updated machine position and always deliver live values, saving you considerable time when aligning your machinery

Alignment intelligence

The best accuracy for industrial applications

The supervisor CCD technology of AT-200 sensors makes them highly tolerant of detrimental external factors, such as vibration and ambient light and provides unrivalled digital filtering capabilities. Simply switch ON the smart Alignment Intelligence filter to automatically adjust sampling time and provide intelligent screen filtering in live alignment mode with outstanding results. The line laser virtually eliminates rough alignment, delivering the most accurate and precise measurement values throughout the alignment process.

Grow your maintenance capabilities

The Horizontal and Vertical shaft alignment apps are part of Acoem’s Augmented Mechanics Ecosystem, the first truly flexible and scalable solution for combining different technologies on the same mobile platform to deliver reliable and precise proactive and predictive maintenance for industrial machinery.

Designed to allow you to continually add to or upgrade as new technologies become available, or as your specific needs change over time, the Ecosystem is made up of a combination of mobile applications, connected wireless sensors.

In addition to the Horizontal and Vertical shaft alignment apps, the Ecosystem currently features:

- The Pre-alignment app, designed to remove the complexity of your laser alignment process, making it faster and more reliable (works with the Acoem wireless Run-out probe)

- The Bearing Defender app, which provides quick first-level information on bearing health based on vibration readings in a matter of seconds (works with an Acoem wireless vibration sensor)

- The Machine Defender app, which provides full rotating machinery with AI-powered vibration diagnostics instantly in the field (works with an Acoem wireless vibration sensor)

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.