What is Vibration and why is it important?

ทำความรู้จักกับ ความสั่นสะเทือน (Vibration)

Vibration is the oscillation or oscillation of objects around the equilibrium point, such as the swing of a pendulum. water pump vibration or the vibration of the speaker, etc., machinery or motors in all kinds of industries There will be a vibration that indicates the condition of the machine. If the measured vibration value is high May be caused by machine imbalance (Ulbarance) or caused by misalignment, which will cause damage to the machine. It may cause a breakdown that directly affects the production process.

Cause of vibration

• Non-standard machine parts Lack of quality checks such as the weight of the equipment. or each piece is not equal placement distance and misalignment

• Warping or deformation of parts due to long-term use.

• Adhesion of undesirable objects on machine parts, causing imbalance (Unbalance), which is the main cause of machine vibration.

1. Damage or wear of various parts of the machine.

Damage caused by Machine (Vibration) wear and tear of the machine. Problematic parts causing machine malfunctions such as couplings, bearings, belts or various seals.

2. The mounting point has shifted due to use.

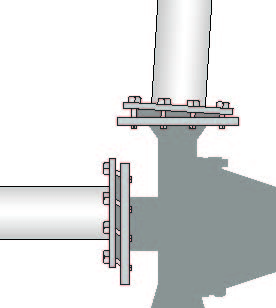

When misalignment occurs Various anchors such as pipes or machine bases There will be stress and strain. Causing to see that the anchor point has moved back and forth, so as not to cause a bigger problem and corrected in time Therefore, it is necessary to check machines on a regular basis

3. Shims can come off easily.

When the motor legs have accumulated fatigue and buckling until the shim comes off or the shim can be easily removed. It is also a sign of soft foot formation.

What is vibration measurement?

Measuring the distance of a vibration (Displacement)

Measuring speed (Velocity)

measurement of acceleration (Acceleration)

• Most commonly measured in millimeters or inches.

• Full wave measurement (Peak to Peak)

• Used for low-speed movement between 1000-1200 RPM or approximately 20 Hz.

• It is a measure of the speed of movement of the vibrating object, “how much is the velocity in each cycle of vibration?”

• Usually measured in millimeters/second. and inch/second To measure speed, we usually measure it in RMS.

• Measure vibrations with frequencies between 20Hz -1,000Hz (or rotational speed higher than 1,200 rpm).

• Changing the ratio of speed per movement.

The time unit of the vibrating object.

• Measure vibrations at high frequencies, i.e. from 10,000 Hz and above.

• High frequency vibration The starting distance of the movement will be small and

At the same time, the movement speed is very high.

What is an FFT Spatrum chart?

Is the frequency graph analysis. which can help isolate problems Vibration of the machine or clearly detected And can confirm the problem along with the Time wave formT graph analysis to inspect the machine if there is a tool to help diagnose the problem Whether analyzing from Time Waveform graphs or FFT graphs, analyzing from parameters such as velocity, acceleration, G-force and DEF, as well as having AI to help analyze problems and flag problems, will help to make decisions from analysts. good

The machine must consist of two main parts:

While the machine works for a while Of course, the machine must have started to have problems. or start to wear and tear All these problems are caused by The parts of a rotating machine are “shafts” and “bearings“.

How can we have surveillance or investigation of these problems? It is strongly advised to use a Vibration Meter or a FALCON Vibration Meter, a tool to measure the vibration of the machine. with state-of-the-art technology Check the problem for us automatically.

Wireless online vibration monitoring

Wireless online vibration monitoring is that we bring a Sensor to measure vibration by installing it on the machine all the time. The vibration value will be collected for analysis. and process data using Time Waveform Analysis

Condition based maintenance is one of the maintenance of the machine to prevent severe damage to the machine. There will be equipment to measure various status values of the machine, such as Unbalanced, Bearing Defect, to monitor the availability of the machine. It allows us to check the status of machine availability. Including in planning to maintain the machine based on the state that the sensor sends data to by the information obtained will indicate the unavailability of various aspects before causing severe damage to our machines Therefore, we should study the vibration of the machine to get the right knowledge.

Application Acoem Machine Defender

If you've ever encountered problems aligning these shafts

Prematurely damaged bearings

The value of Vibration is increased.

Increased friction cause more energy loss

There is an increase in noise

These problems will be gone. If using standardized tools to get accurate values

So we should use the right tools. and standardized To reduce the burden of long-term expenses, such as premature maintenance, and also save time for the technician team and the factory as well.

Bearing Defender

Vibration measuring instrument Check for machine health problems. Breakdown Prevention

– Know the analysis result in only 10 seconds from the 3-axis wireless sensor.

– AI (Accurex) that reads automatically (ZYXtrum FFT spectrum 3 axis)

– Photo taking function Listen to the sound of ball bearings. confirm frequency The cause of the problem of vibration problems

How good will it be

If there is a wireless vibration meter (Wireless Vibration), vibration will automatically

FALCON Smart Portable Vibration Analyzer

A smart tool that can help you find out the real problems of all 3-axis machines in seconds.

“Eagle“is a Wireless Vibration instrument used for measuring Vibration wirelessly.

and send data online via LAN / WiFi / 4G

Therefore, we no longer need to go to the site manually, just have a computer connected to the network, able to monitor and analyze the condition of the machine from anywhere. Suitable for areas that are difficult to reach and are highly dangerous.

Reduce the risk of workers entering and inspecting machines What’s more, Eagle can also store the value quite often, 1 time per hour. The battery can be used for up to 5 years and can also set the vibration alarm value. When the machine has a problem, the report can be sent to Email immediately.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.