What is Pulley alignment – Belt alignment ?

Pulley alignment is the alignment of the belt.

Setting up pulleys in the old days may have used tendons, ropes or steel rulers to set the line, requiring a professional team. and the expertise of the users And there may be errors and high discrepancies. because of the limitations of the tool and skill of the user, etc.

What is a Pulley?

So, we must pay attention to the importance and basis for choosing the right type of pulley and maintaining it. because in the past many Pulley will not be given as much attention as it should be.

Duties of Pulley

The pulley is responsible for changing direction. and control the tension or looseness of the belt and sometimes acts to adjust the belt so that the belt can walk in alignment throughout the movement of the belt

How many types of pulleys are there in the transmission and conveying system?

- Standard Pulley

- Idler Pulley

- Variable speed Pulley

- Step Pulley

- Poly Multi Ribbed Belt Pulley

- Timing Pulley

- Conveyor Pulley

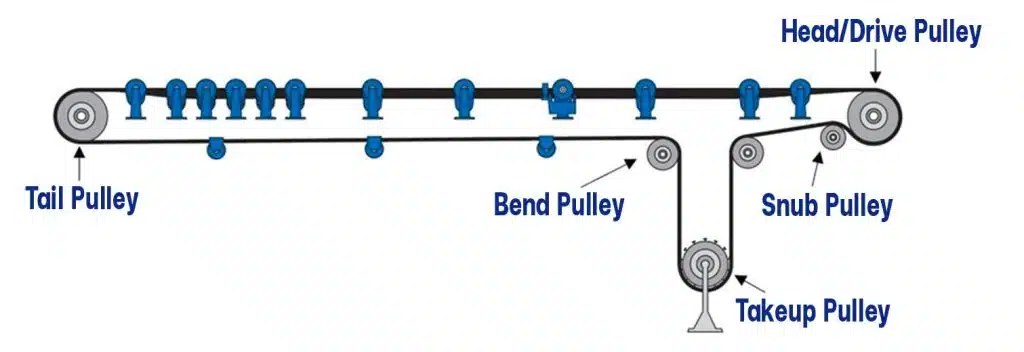

Installation location of the Pulley roughly.

Tail Pulley (ล้อท้าย)

Used to check the shaft of the machine is bent or crooked because it will cause the alignment to be inefficient. and cause damage to the machine itself

Bend Pulley (ล้อดัด)

may arise from the assembly or after using it for a long time causing the bearing to deteriorate

Head Pulley (ล้อหัว)

Used to check the run-out of the shaft or shaft oscillating caused by non-standard installation.

Snub Pulley (ล้อกดสายพาน)

Used to check the run-out of the shaft or shaft oscillating caused by non-standard installation.

Take-Up Pulley (ล้อปรับความตึง)

may arise from the assembly or after using it for a long time causing the bearing to deteriorate

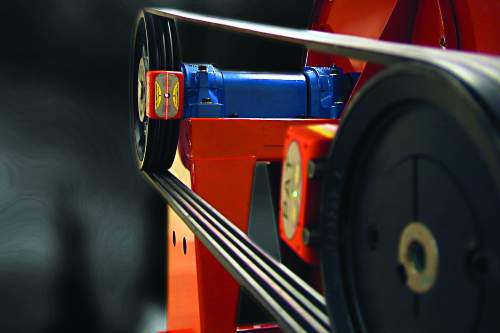

Belt alignment Laser

FAAD presents a tool that allows you to Belt alignment is easy, convenient, fast and inexpensive, plus world-class quality with laser belt alignment from PAT (Belt Alignment Laser).

The PAT’s Belt Alignment Laser fires a laser away from the source. Shot out to a photoreceptor that clamps on the pulley on the other side that There is a level to measure the inclination. and laser light that can be clearly seen with the naked eye Makes setting up easier and faster This allows the installer to move one of the pulleys to move precisely in line.

Laser alignment is increasingly used in modern industrial plants, saving time and achieving high accuracy. Help maintain the belt and reduce Breakdown of the machine. more efficient

How good is Pulley alignment?

Align the belt and pulley. prevent machine downtime

- Reduces belt and pulley wear.

- Reduce friction and energy consumption.

- increase the efficiency and production capacity of the machine

- Reduce replacement costs and downtime

Easily align the pulley belt with the PAT (Pulley Alignment Tool).

The problem you overlooked Might cause enormous damage

Faadtech gave an example of a problem. That most users tend to ignore, that is the problem of the belt itself.

P A T IS A Pulley Aligment Tool

Tools to help you align the belt

To prevent the occurrence of injection of the belt. and heavy work of the machine causing many other problems to follow

- Easy to use, no expertise required.

- Laser firing range up to 6 m

.The detector has a laser dial with a reference line. Makes alignment easy - There are V-shaped brackets according to various sizes. for various types of pulley grooves

How to easily install PAT in 12 seconds

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.