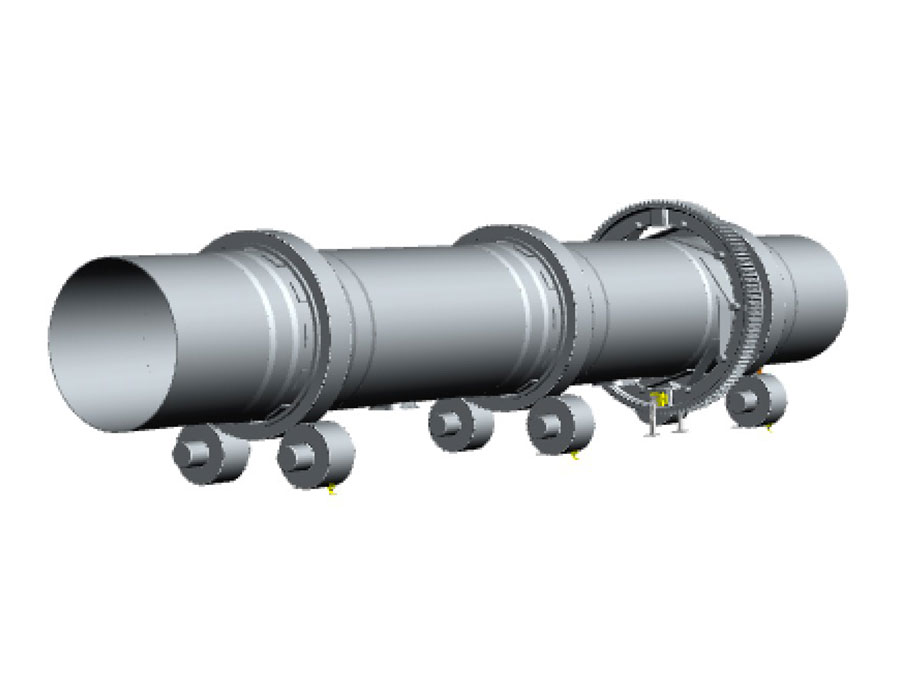

Mechanical Kiln Monitoring System

Introduction

The MKM-System is an on-line measuring unit to detect abnormalities during kiln operation which can lead to mechanical failures on any rotary kiln system (with more than 2 Stations). The main objective is to detect such abnormalities (thermal or permanent kiln cranks, lack of tire play) at an early stage. Analog signal exchange (4 – 20 mA) allows the plant to connect directly with the plant control system to set alarm levels and to take adequate counter-measures.  Furthermore the equipment is storing the measured data to a memory card in a way to perform off-line analysis at any stage to verify the origin of upset condition (process or mechanical).

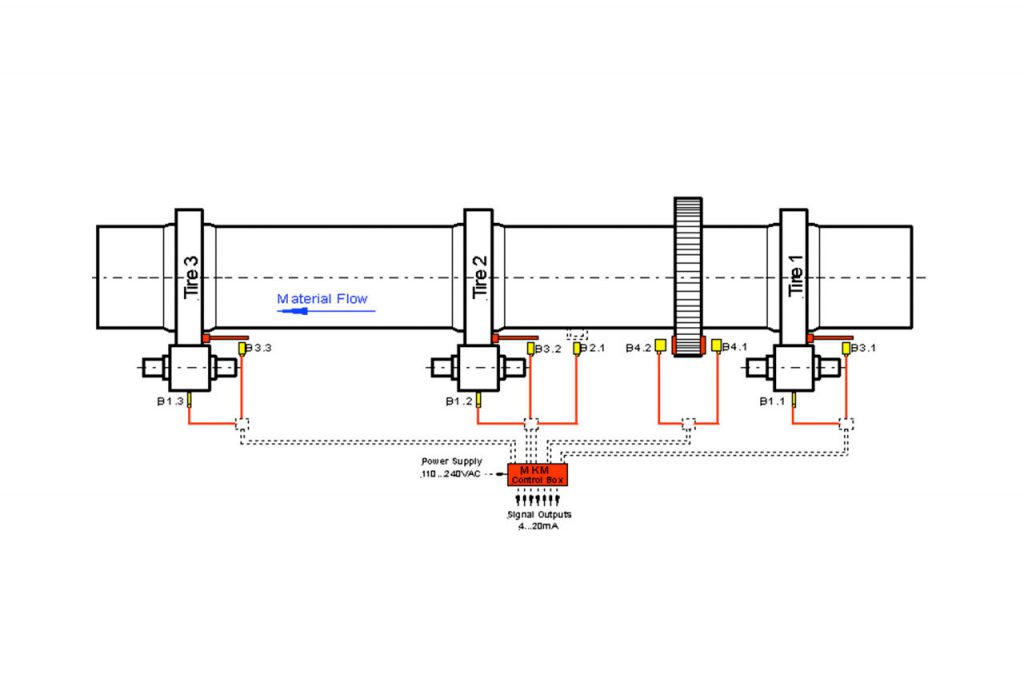

Measuring Principle

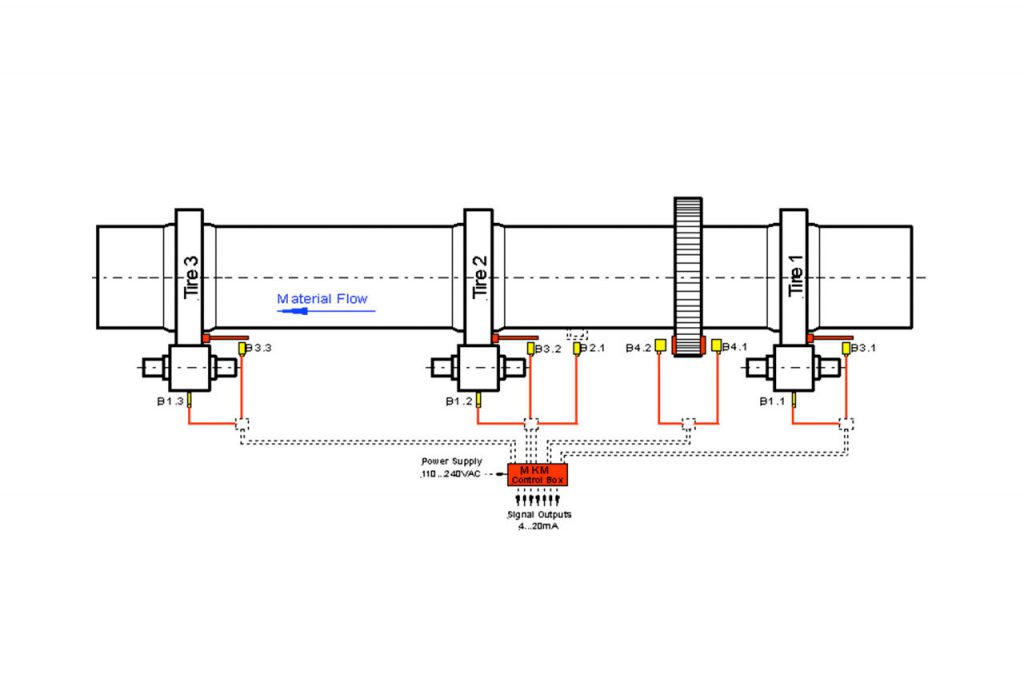

General Setup:

To detect the different abnormalities the system consists of a main Unit and 3 additional Unit.

Main unit:

Mechanical Kiln Monitoring System (MKM) – Control Box

Additional units:

MKM-System – Roller Shaft Bending Measurement

MKM-System – Relative Tire Movement Measurement

MKM-System – Axial Kiln Position Measurement