Circulation systems

Circulation lubrication – an introduction

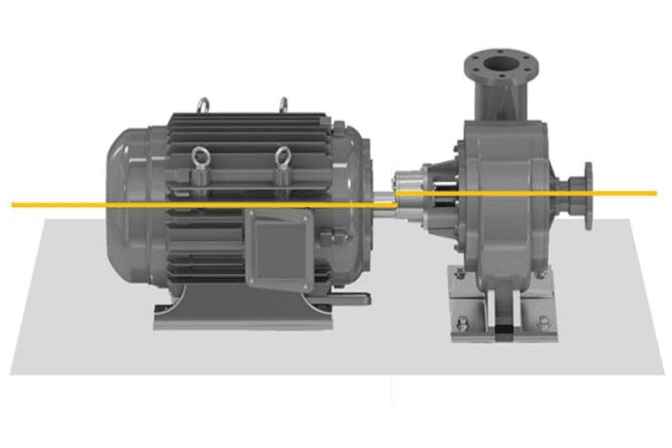

Some lubricated objects (like fast moving, heavy loaded bearings or bearings with the need of heat transfer, or gear boxes) are often lubricated by a circulation system. The system consists of a pump unit with tank, filter and cooler, a pipe system and a flow meter for each lubrication point. The system is usually controlled by a separate controlling unit, but can also be controlled via the machine’s PLC. Each lubrication point has not only an inlet but also a return

line which enables for the oil to pass the bearing or gear box. A constant pressure is being sustained in the pipe line between the tank and the flow meter. The pressure drop over the flow meters is then constant as well, which is necessary to maintain a regular and smooth flow to each bearing. The pump works continuously. The return oil from the bearings has absorbed contaminations, heat, and perhaps moist. It is therefore filtered and cooled down. It can also be

dehydrated if the application demands for it.

Assalub have for many years been doing rebuilds and new installations of circulation systems as:

New installations, planning, design and installations

Replacing Flow Meter

Replacing oil containers and pumping stations

Rebuilds and additions of pressure and return pipes

We work with FluidHouse who manufacture what perhaps is the worlds most modern oil circulation pumping station. Compared to traditional oil circulation pumping stations, it can reduce the container size by 70 %.

Our primary supplier of flow meters is Kytölä who we have been in business with for several years and whose flow meter av become our and many of our clients favorite. Certain models kan be serviced and repaired while used since it’s equiped by a bypass / service valve.