Steam Trap Testing

Reduce Energy Costs and Increase Process Stability with Ultrasonic Testing Devices

The regular inspection of valves and steam traps is essential for preventive maintenance. The early detection of steam trap leaks or fails and signs of wear leads to increased operational reliability, and considerable cost savings.

Advantages at a Glance

Reduce energy costs by up to 20 %

Increase process stability

Check all types and brands quickly and inexpensively

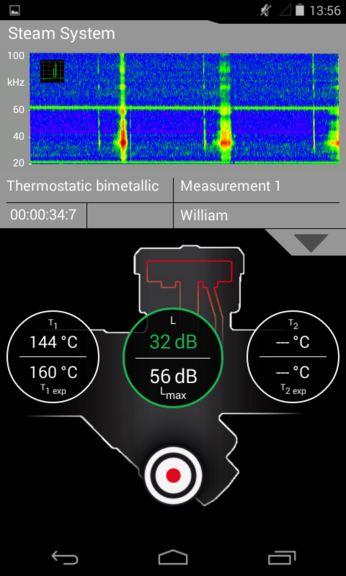

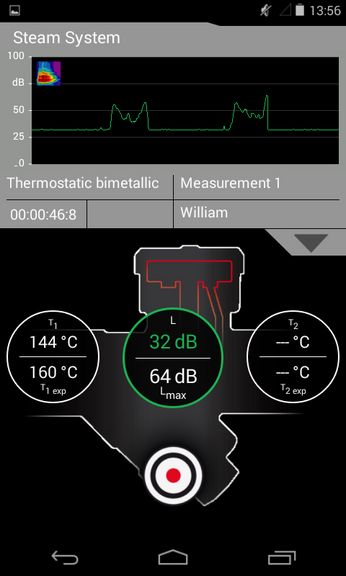

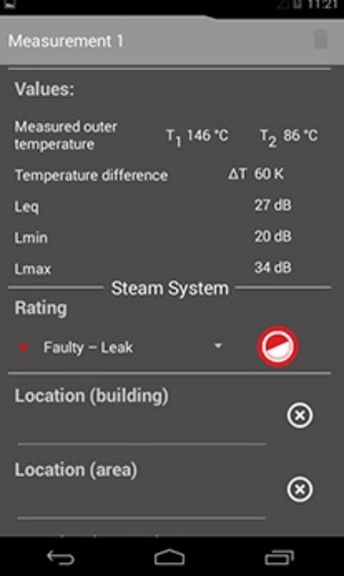

SteamExpert App for steam trap testing for SONAPHONE

SteamExpert Software module for SONAPHONE DataSuite

Reporting and Trending

MYSONAPHONE

Product and Software Support for your SONAPHONE!

Leak Detectors

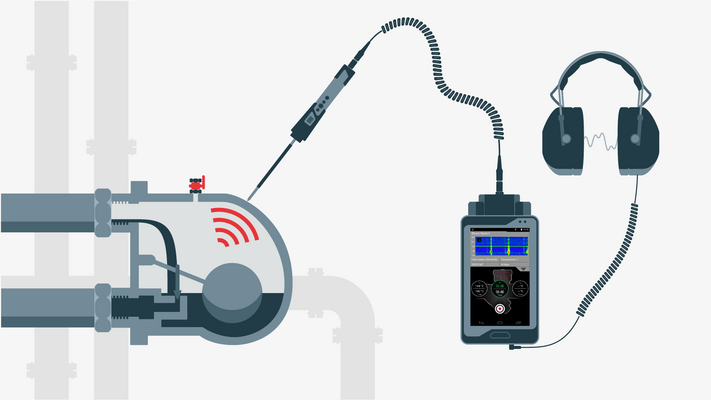

The ultrasonic testing device SONAPHONE is used for steam trap and valve inspections in many branches of industry.The SONAPHONE devices can be used for the testing of the functionality of any type of steam trap e.g. for float, thermodynamic and thermostatic traps or for valves in systems with a flow of steam. The device enables the control of the proper functionality of steam traps and also allows an estimation of any losses of steam within the system.The functionality of steam traps and valves is tested by analysing the typical ultrasound and temperature of the respective installation.

Our complete solutions for steam trap testing includes:

SONAPHONE digital ultrasonic testing device

BS20 broadband structure-borne sound and temperature sensor

SteamExpert app for SONAPHONE

SteamExpert module for PC Software SONAPHONE DataSuite

SteamExpert App for Digital Ultrasonic Testing Device Sonaphone

With the SteamExpert app, steam traps of all types and brands can be tested quickly and inexpensively. The app was specially developed for the digital ultrasonic testing device SONAPHONE in combination with the ultrasonic and temperature sensor BS20. The tester is guided intuitively through the test process. In combination with the SONAPHONE DataSuite software, the tests can be planned in the form of routes and the results can be comprehensively analyzed and evaluated.

Reduction of error susceptibility due to implemented test sequence

Selection of arrester types directly in the app (thermal, thermodynamic, mechanical)

Input of pressure and emissivity

Plausibility check: measure inlet temperature and compare with expected temperature

Efficient recording of relevant test data by recording information such as text and image directly at the measuring point

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[HS-AA0310203] - M6 Face Carbide Tipped Spot Face Tool Set](https://www.faadtech.co.th/wp-content/uploads/2024/07/HS-AA031-300x300.jpg.webp)

![[HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set [HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set](https://www.faadtech.co.th/wp-content/uploads/2024/07/HS-AA031-600x600.jpg.webp)