Ultrasonic Leak Detection

In Compressed Air, Inert Gas and Vacuum Systems

Nowadays saving energy is an important topic in all areas in which compressed air systems are used. The finding and elimination of leaks in compressed air systems alone can save up to 35 % of the energy costs associated with the use of a compressor. Regular ultrasonic inspections and preventative maintenance can also increase the operational reliability of equipment.

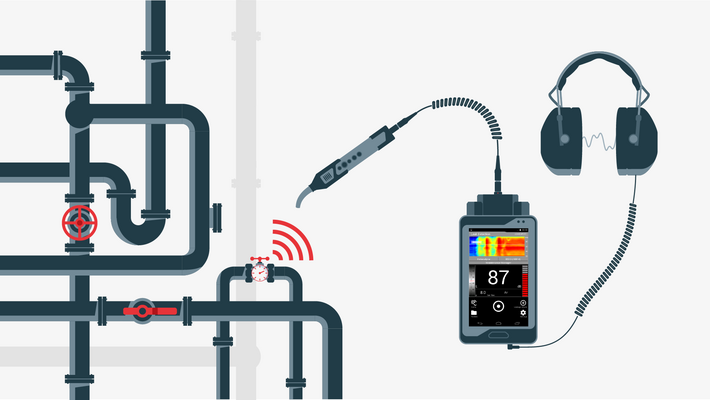

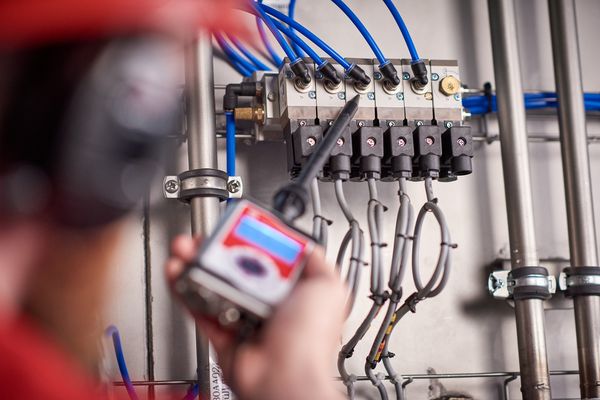

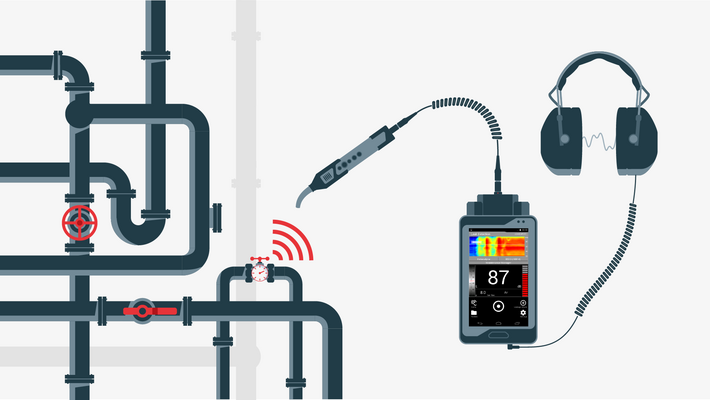

Ultrasound Inspection

Inspection with an ultrasound detector (Ultrasound Inspection)

Before getting to know the instrument, you must first know what ultrasound

is ? Ultrasound waves are sound waves with frequencies above the range that can be heard by humans. which is a high frequency sound wave but low power short wavelength They tend to move in a straight line and are easily absorbed by energy. And there are 3 causes of ultrasound waves in factories: Friction, Impact and Turbulence.

Inspection with an ultrasound detector (Ultrasound Inspection)

Compressed air production It’s a costly process. And the loss of compressed air as a result of leaks worsens system performance. and cause unnecessary expenses

SONAPHONE ultrasound detectors and SONOASCREEN cameras can quickly and easily detect leaks. Compatible with compressed air, inert gas and vacuum systems

การใช้งานเครื่อง Sonaphone และ SonaScreen

SONAPHONE® Pocket

SONAPHONE® T & SONOSPHERE

SONAPHONE Pocket

Advantages of Ultrasonic Leak Detection

This ensures all major aspects of pulley misalignment are resolved. This belt alignment tool is so easy to use, a single operator can perform the pulley or belt alignment task in minutes with no training! Comes in its own durable carrying case.

Detect leaks in compressed air, inert gas and vacuum systems

Save up to 35 % of the energy costs associated with the use of a compressor

Patent-pending method for leak classification and evaluation in l/min

LeakExpert: Specific app for leak detection and classification for SONAPHONE

Generate leak reports

LEAKEXPERT

Specific app for leak detection and classification

Leak Detectors

Leak Calculator

The process of estimating the amount of leakage in a compressed air system is part of DIN EN ISO 11011. This process provides data for energy management systems in accordance with DIN EN ISO 50001. The leakage calculator is based on the leakage loss, which were determined and classified with the SONAPHONE ultrasonic testing device with LeakExpert app. For the calculation, the compressed air index, the energy costs and the production hours must also be known.

Disclaimer

SONOTEC has developed a process for classifying and estimating the total leakage losses of a system to the best of its knowledge and ability, based on flow acoustics methods.

SONOTEC shall in no way be held liable for the results generated through the application of this process, nor for any decisions made on the basis of such results. All actions taken by the end user based on the results are the sole responsibility of the end user, who accepts full liability for any such actions.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set [HS-AA0310203] – M6 Face Carbide Tipped Spot Face Tool Set](https://www.faadtech.co.th/wp-content/uploads/2024/07/HS-AA031-600x600.jpg.webp)

![[ASH456] – HIGH TEMP ACCELEROMETER [ASH456] – HIGH TEMP ACCELEROMETER](https://www.faadtech.co.th/wp-content/uploads/2024/07/dASH456-2-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH214-3A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH214-3A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/06/MH214-3A-3-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH140-1A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH140-1A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/MH140-1A-1-600x600.jpg.webp)

![Magnet Mounting Base with 1/4-28 [MH137-1A] Magnet Mounting Base with 1/4-28 [MH137-1A]](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-MH136-1A-1-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH128-1A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH128-1A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-MH128-1A-2-600x600.jpg.webp)

![Multipurpose 2 Rail Magnet Mounting Base [MH114-3A] CTC Multipurpose 2 Rail Magnet Mounting Base [MH114-3A] CTC](https://www.faadtech.co.th/wp-content/uploads/2024/05/CTC-TREA330-2-600x600.jpg.webp)