STRAIGHTNESS WITH AN EDGE

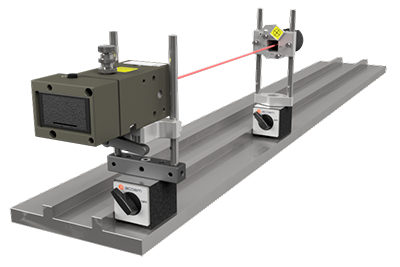

Straightness measurement

The straightness application is measured in two axes, where the laser beam is used as a reference. The deviation in distance between the laser beam and the measurement object is measured in two or more positions with the use of a receiver.

The program allows for up to 99 points to be measured.

Typical straightness applications are measurements of machine guides, machine beds, machine ways, and guide rails.

How to do a straightness measurement

1. Configuration

Quick and easy to configure

Pre-defined configuration

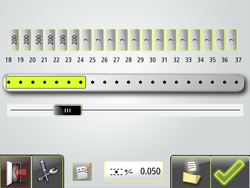

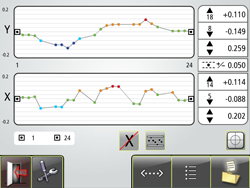

2. Measurement

Live values during the adjustment phase

The angle guide displays the accepted (green) measurement point registration area

Green arrows show you in which direction to adjust towards zero

Color-coded measurement values

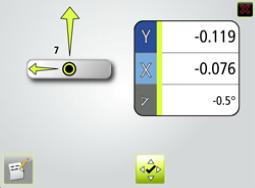

3. Adjustment

Live values during the adjustment phase

The angle guide displays the accepted (green) measurement point registration area

Green arrows show you in which direction to adjust towards zero

Color-coded measurement values

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.